Automatic measurement method of bearing oil groove based on structured light

A technology of automatic measurement and measurement method, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of not being able to determine the actual size of the oil groove, low measurement accuracy of tracing, and low measurement accuracy, so as to improve detection efficiency, Simple structure and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

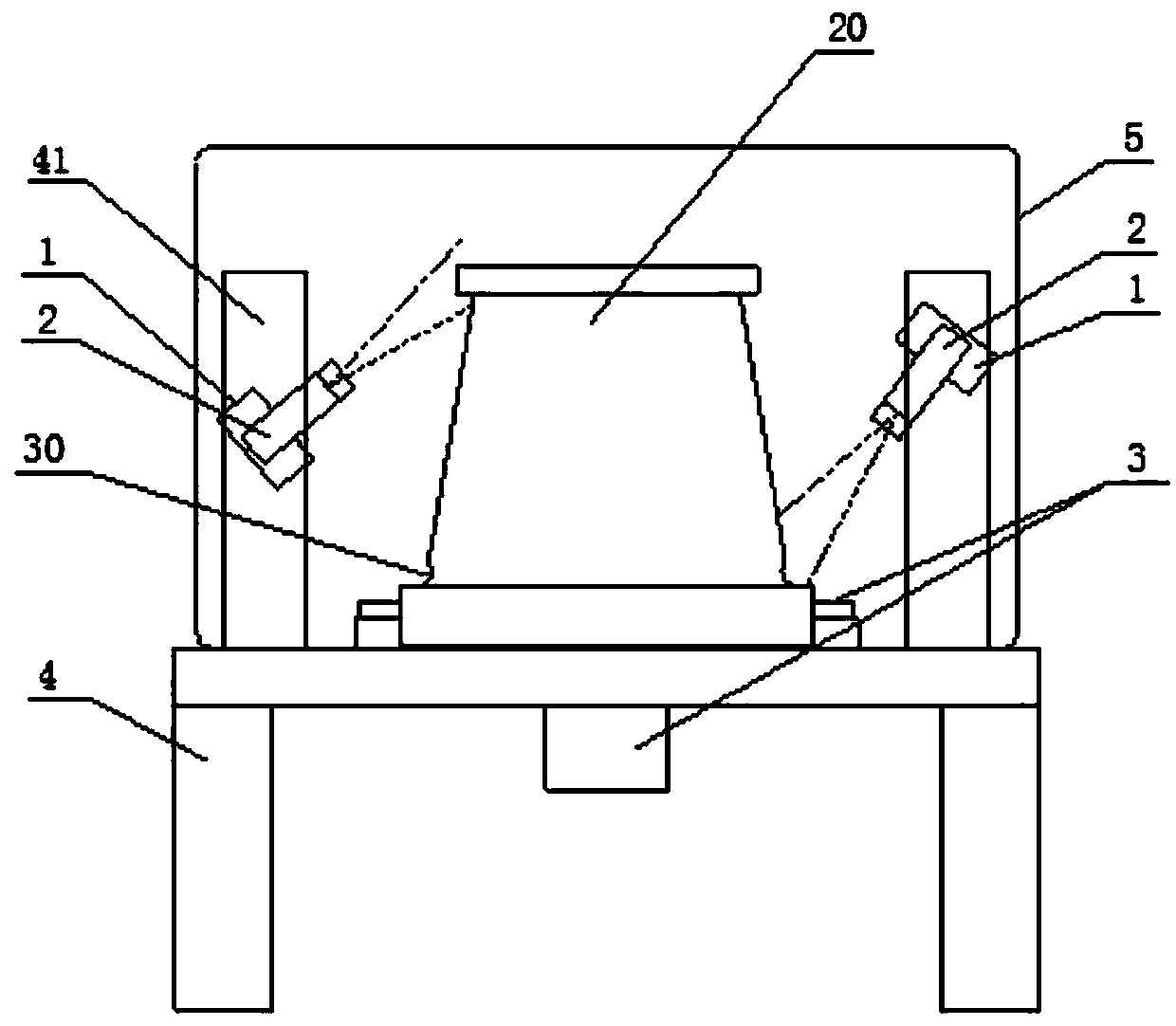

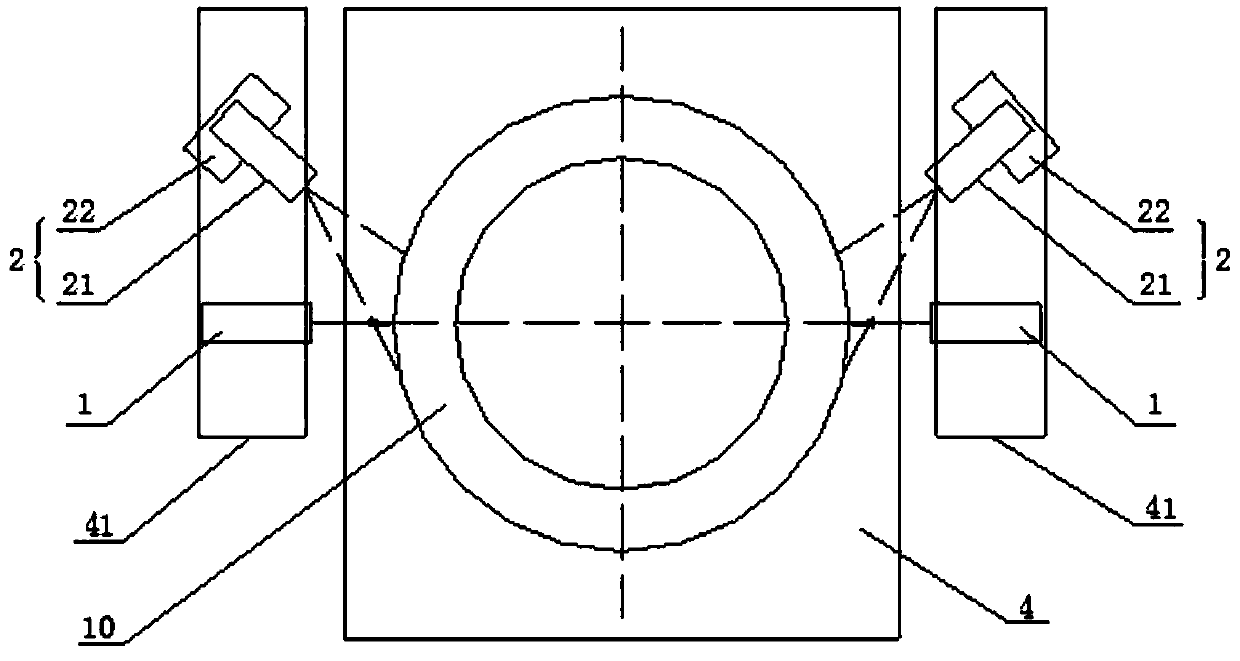

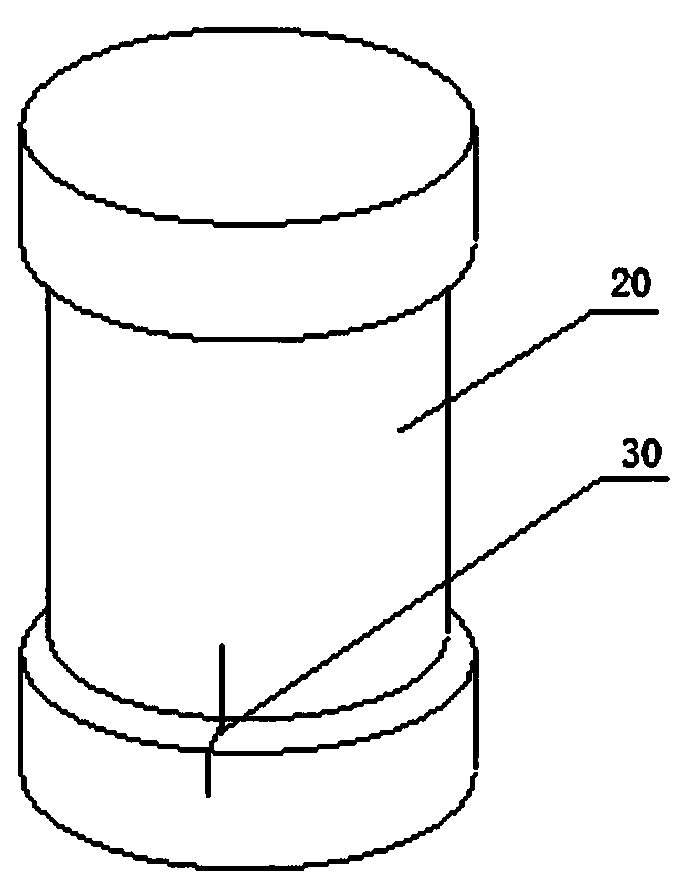

[0041] Figure 1 to Figure 3 It shows an embodiment of a bearing oil groove automatic measurement system based on structured light of the present invention, which includes a line laser emitter 1, a vision probe 2 and a driving turntable 3, and the bearing 10 to be tested is fixedly installed on the driving turntable 3 and It rotates synchronously with the driving turntable 3. In this embodiment, the driving turntable 3 includes a turntable and a motor for driving the turntable to rotate. The direction of the line laser beam emitted by the line laser transmitter 1 passes through the rotation axis of the inner ring of the bearing to be detected, and a section of contour generatrix 30 can be formed on the surface of the oil groove of the inner ring of the bearing. Driven by the continuous rotation of the driving turntable 3, many Segmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com