Liquid crystal panel drive circuit and LCD

A liquid crystal panel and driving circuit technology, applied in static indicators, instruments, nonlinear optics, etc., can solve the problems of screen flicker, liquid crystal shift, liquid crystal clamping screen flicker, etc., and achieve the effect of avoiding flicker.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

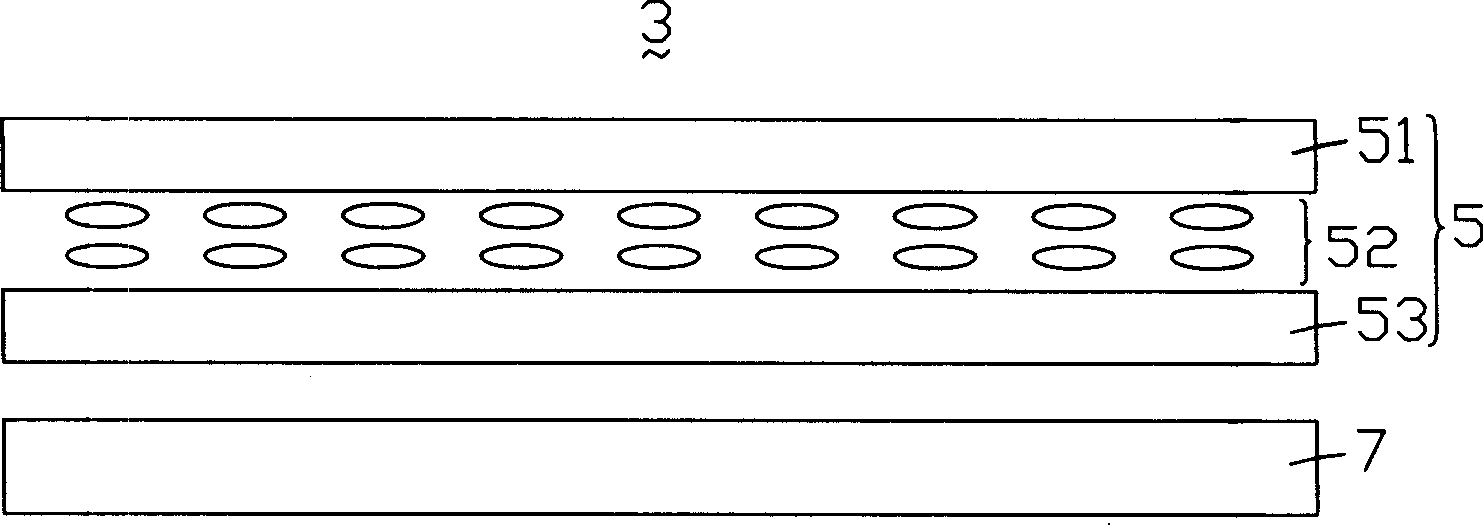

[0018] see figure 2 , is a schematic structural view of a preferred embodiment of the liquid crystal display of the present invention. The liquid crystal display 3 includes a liquid crystal panel 5 and a backlight module 7 for providing planar light to the liquid crystal panel 5 . The liquid crystal panel 5 includes an upper substrate 51 , a lower substrate 53 and a liquid crystal layer 52 sandwiched between the upper substrate 51 and the lower substrate 53 . The liquid crystal panel 5 is driven by a liquid crystal panel driving circuit (not shown).

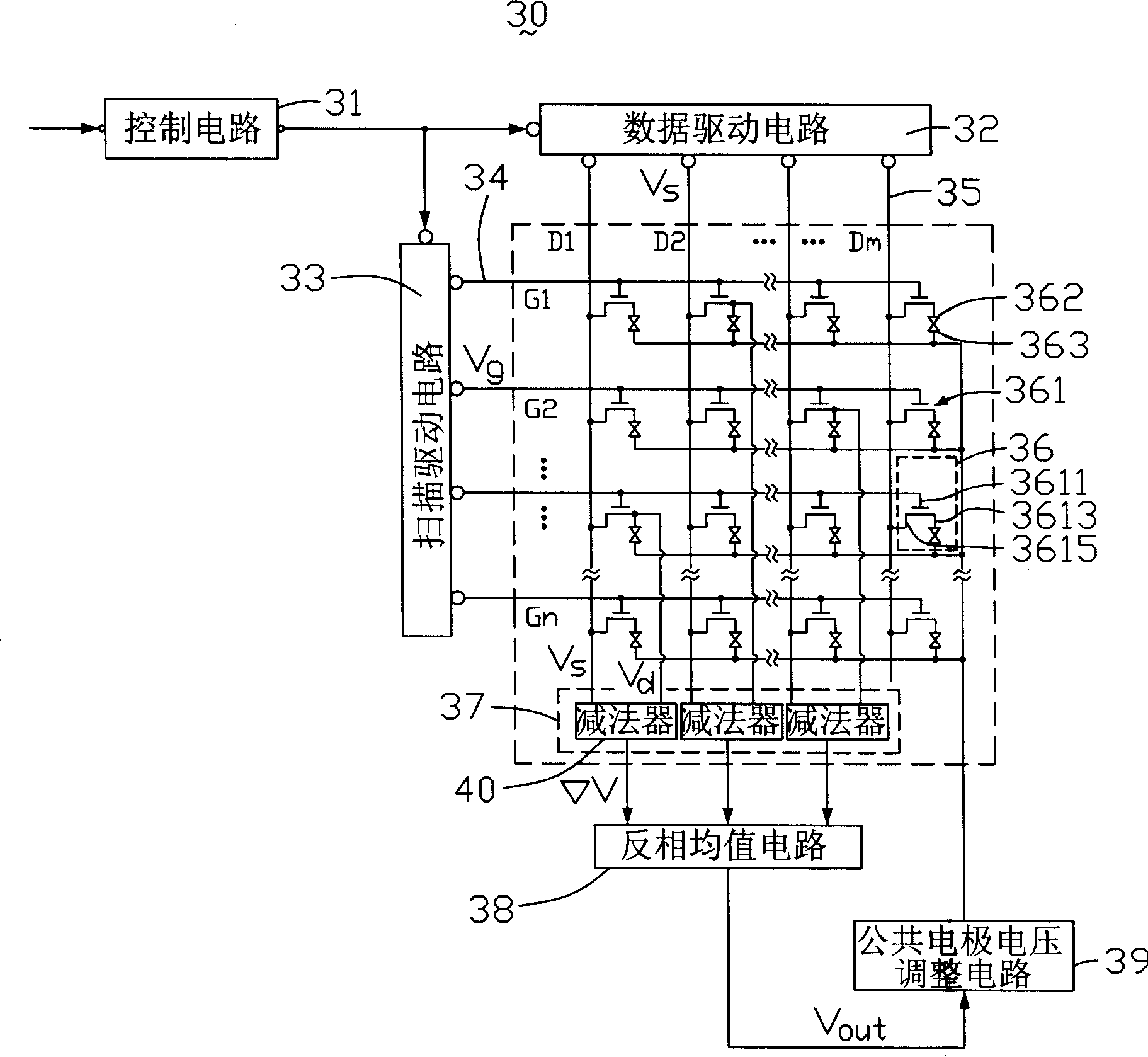

[0019] see image 3 , is a schematic circuit diagram of a liquid crystal panel drive circuit for driving the liquid crystal panel 5 . The liquid crystal panel driving circuit 30 includes a control circuit 31, a data driving circuit 32, a scanning driving circuit 33, a plurality of scanning lines 34 parallel to each other, and a plurality of data lines 35 parallel to each other and vertically insulated from the scanning lines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com