Sheathed-element glow plug

A glow plug and rod-shaped technology, which is applied to heating element materials, lighting and heating equipment, combustion ignition, etc., can solve the problems of excessive current, damage, and destruction of heating body materials in heating devices, and achieve simplified operation and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

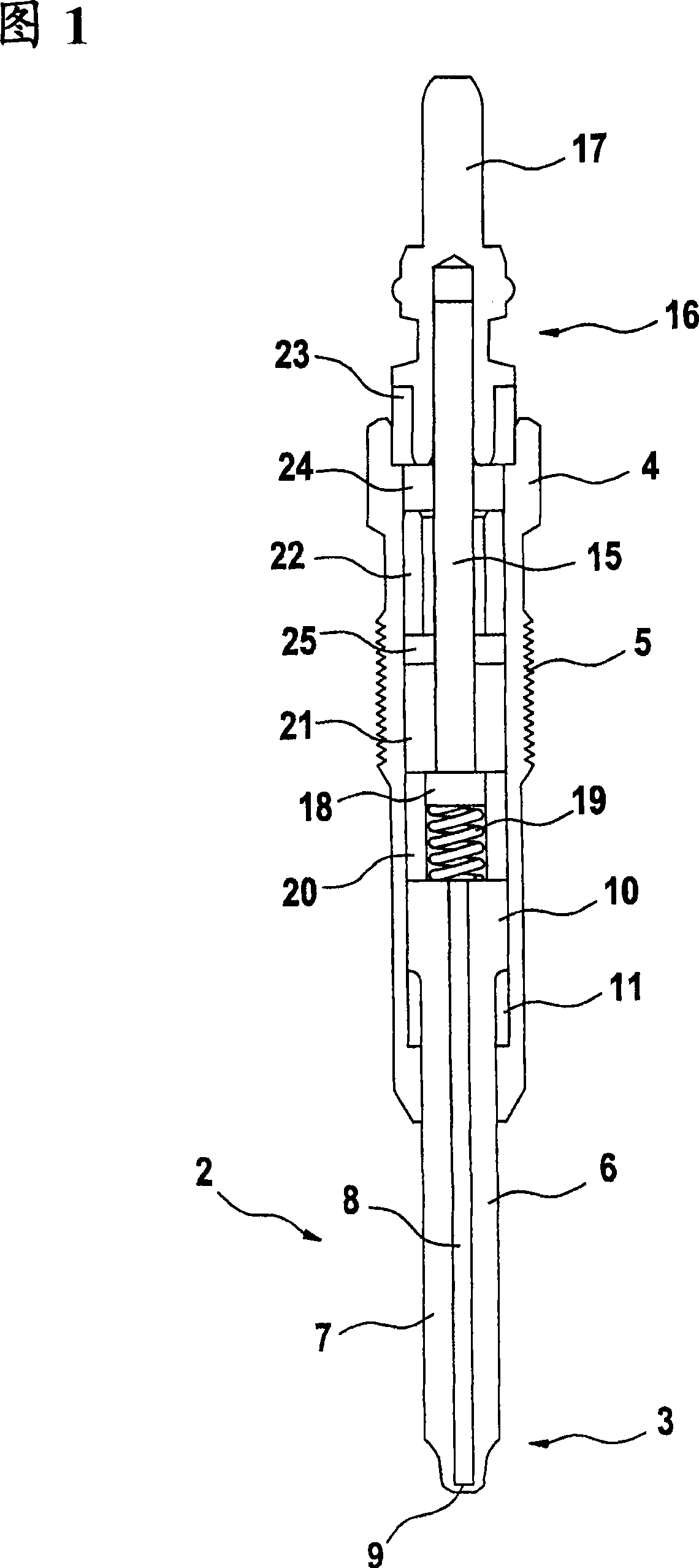

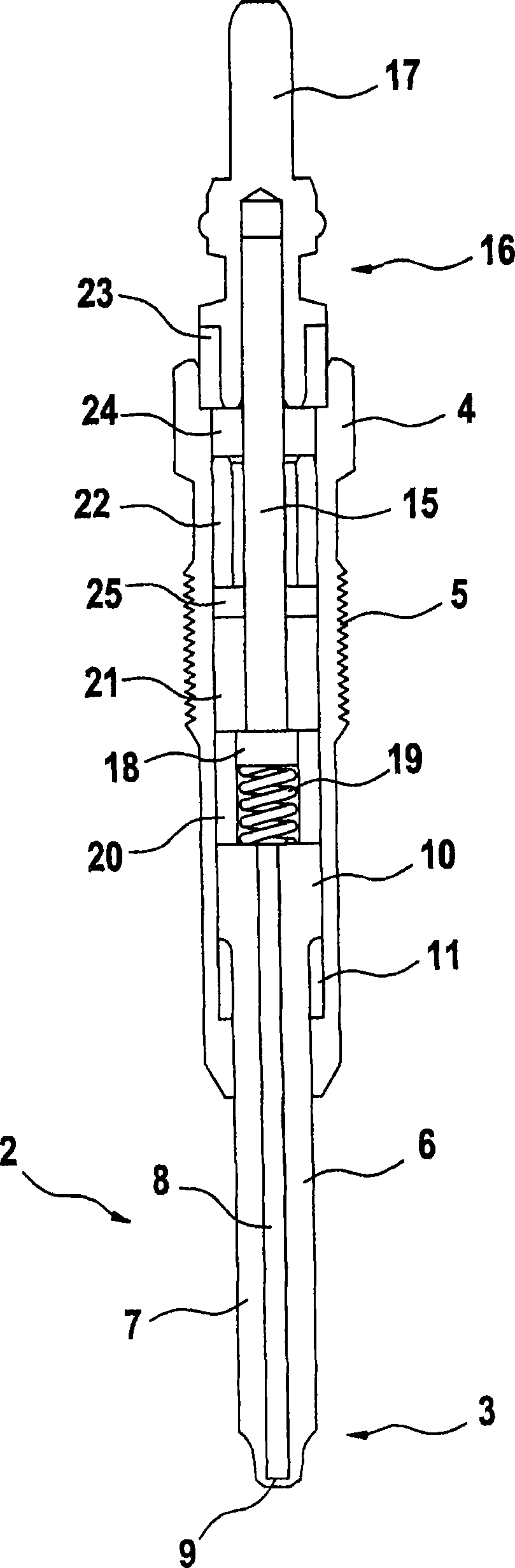

[0015] figure 1 A schematic view of an exemplary embodiment of a rod-shaped glow plug 1 is shown. The rod-shaped glow plug 1 can be specially designed as a rod-shaped glow plug 1 for an air-compressed, self-ignition internal combustion engine. During operation, the heating body 2 of the glow plug 1 protrudes with its combustion chamber-side end 3 at least partially into the combustion chamber of the internal combustion engine. For pre-chamber engines and swirl chamber engines, the heating body 2 can extend into the pre-chamber or swirl chamber; for direct fuel injection engines, the heating body then extends into the combustion chamber of the engine. The rod-shaped glow plug 1 according to the invention is also suitable for other applications.

[0016] The glow plug 1 has a housing 4 which preferably consists of a metallic material. On this housing 4 there is an external thread 5 by means of which the glow plug 1 can be screwed into a bore of an internal combustion engine o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com