Compressed spring type guide screw transmission platform lifting mechanism

A screw drive, platform lifting technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of high maintenance technology and cost, high working intensity, poor synchronization and reliability, etc., and achieve good ergonomic adaptability, The effect of strong environmental adaptability and good self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

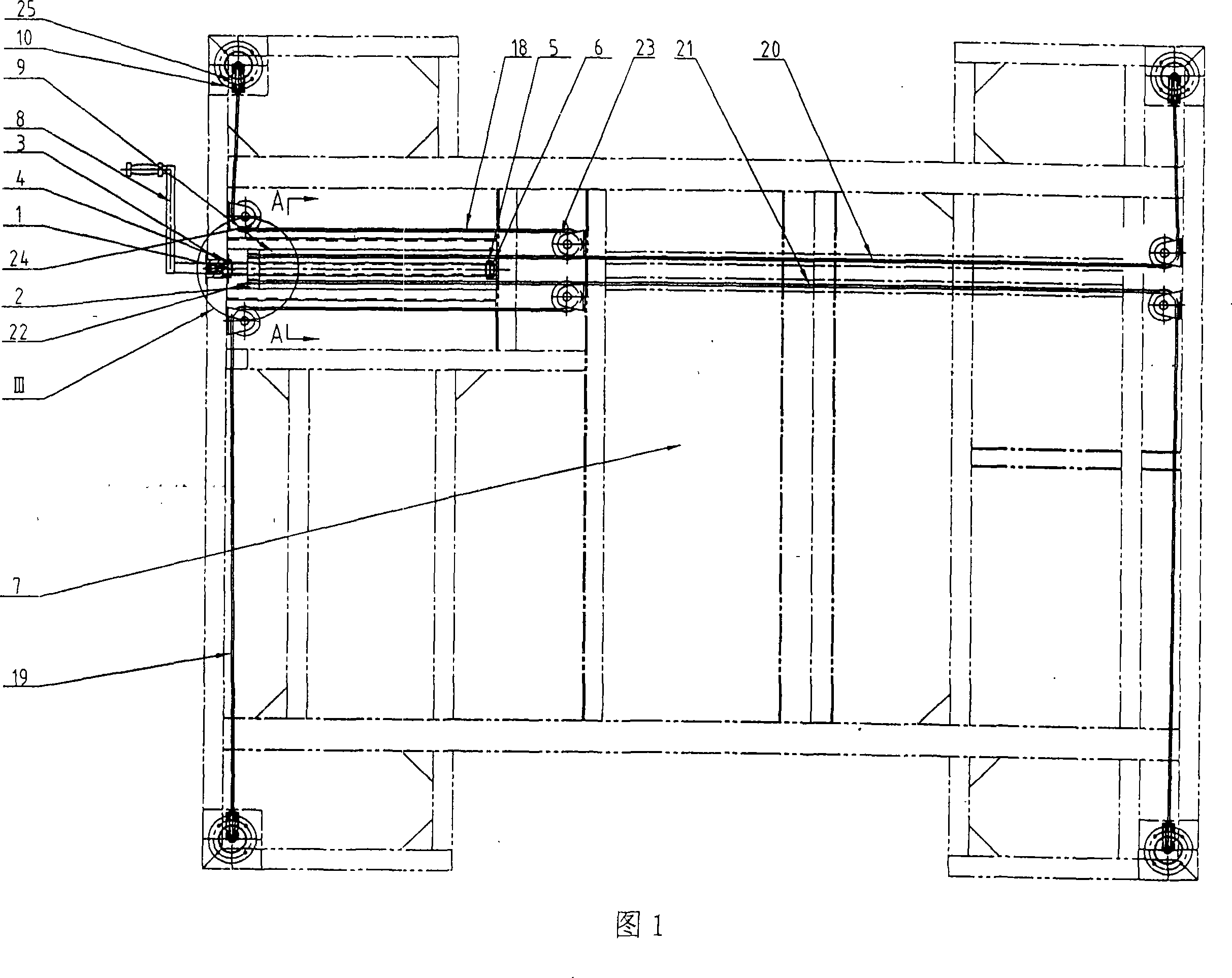

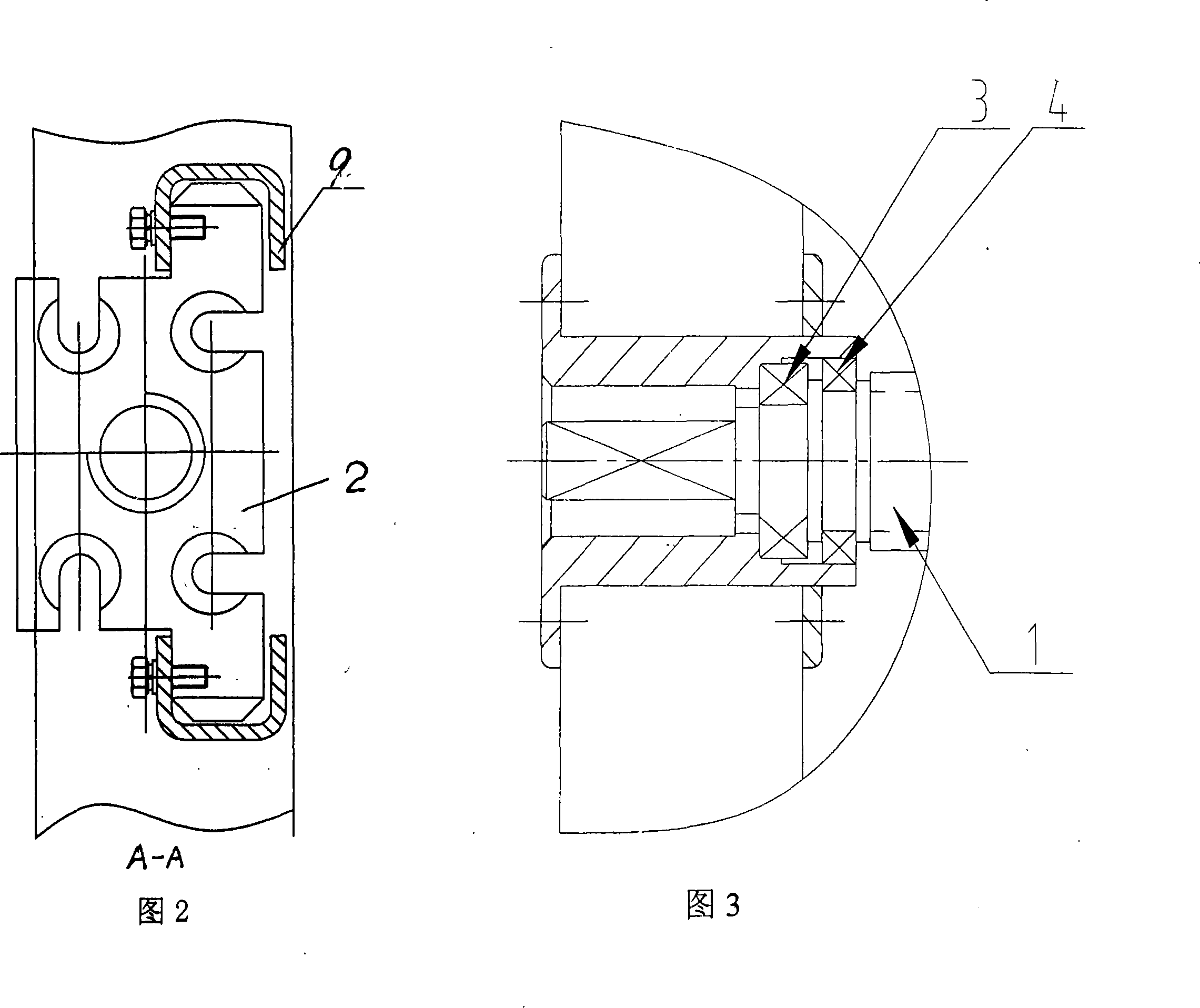

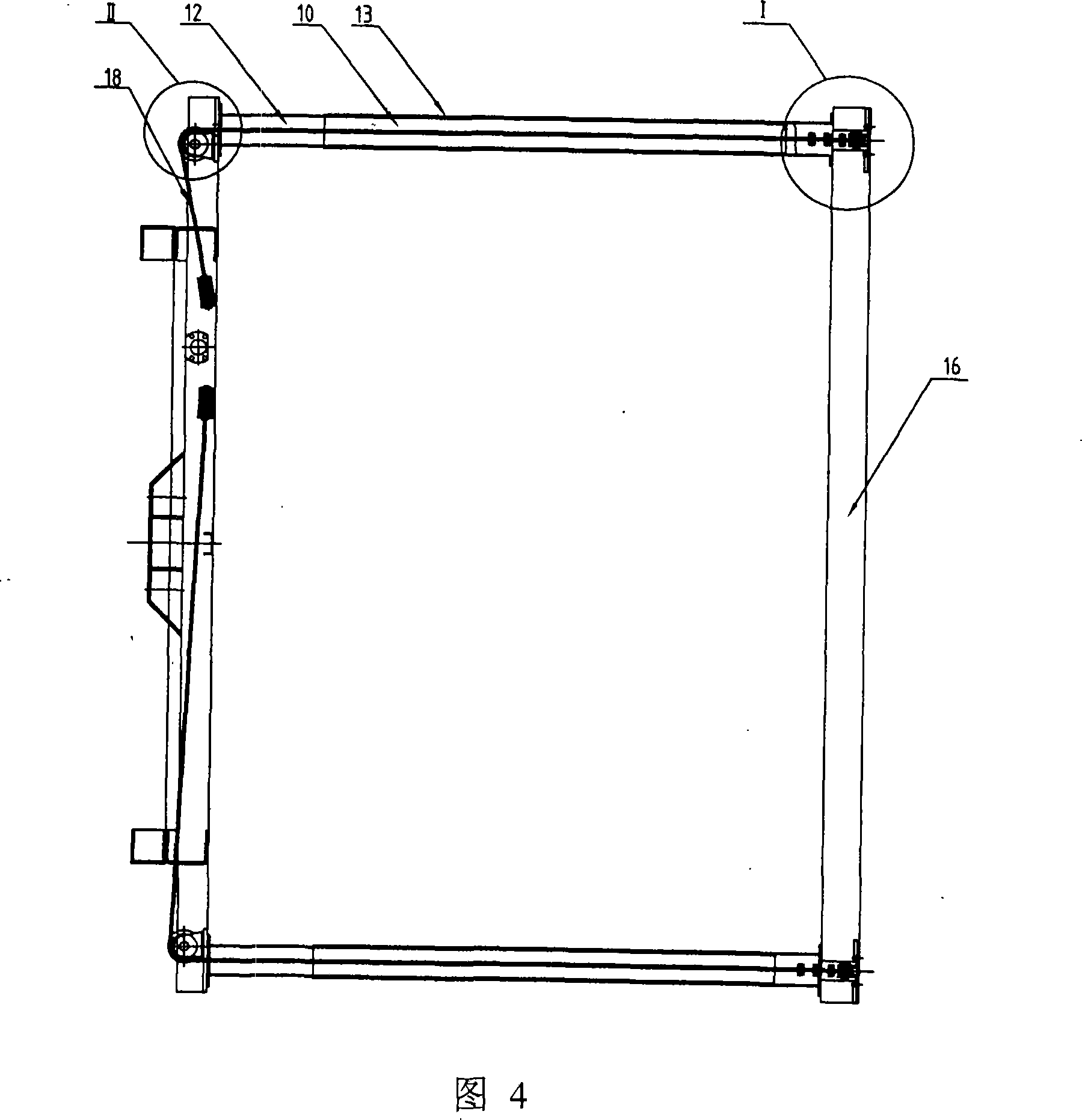

[0017] As shown in the figure, a compression spring type screw drive platform lifting mechanism includes a screw drive pair, a platform base and a ceiling, and the screw drive pair includes a screw rod 1 and a screw nut 2 . The lead screw is fixed on the base 7 of the platform through bearing 3, bearing 4, bearing 5 and bearing 6, wherein 4 and 5 are thrust bearings, 3 and 6 are rolling bearings, the lead screw 1 is driven by the leveling and lifting handle 8, and the screw nut 2 and the lead screw 1 are screwed together. Connected and placed on the guide rail 9 of the base 7; the compression spring mechanism includes a column 10 and a compression spring 11. The column 10 is composed of an inner tube 12 and an outer tube 13. The inner tube 12 is fixed to the base with bolts 14, and the outer tube is fixed to the ceiling 16 with bolts 15. The inner tube 12 can slide relative to the outer tube 13. The gap between the inner tube and the outer tube is 1 mm; the compression spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com