Fluid pressure circuit

A fluid pressure and circuit technology, which is applied to fluid pressure actuators, servo meter circuits, servo motors, etc., can solve the problems of not being able to improve linkage, and achieve the effect of improving linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

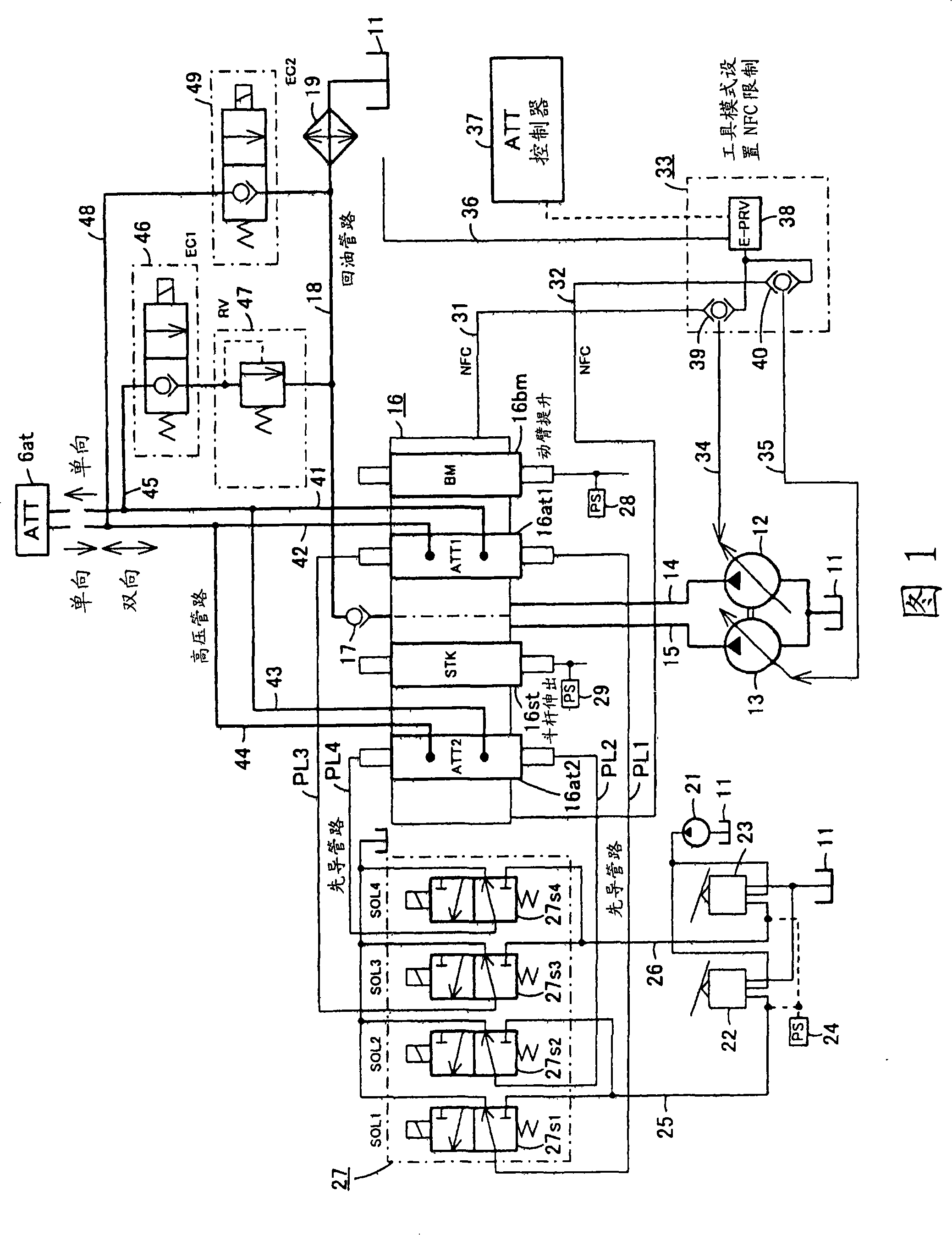

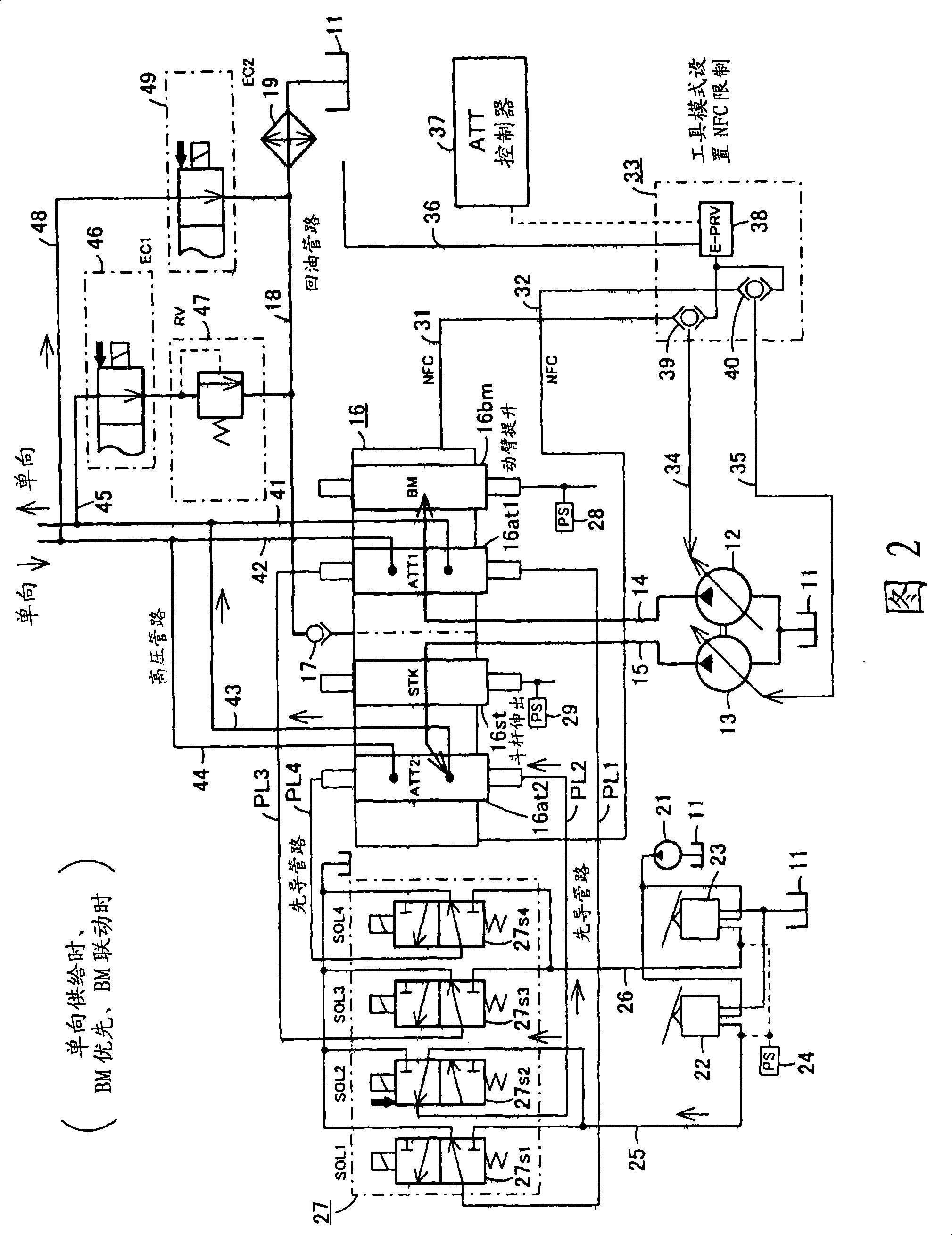

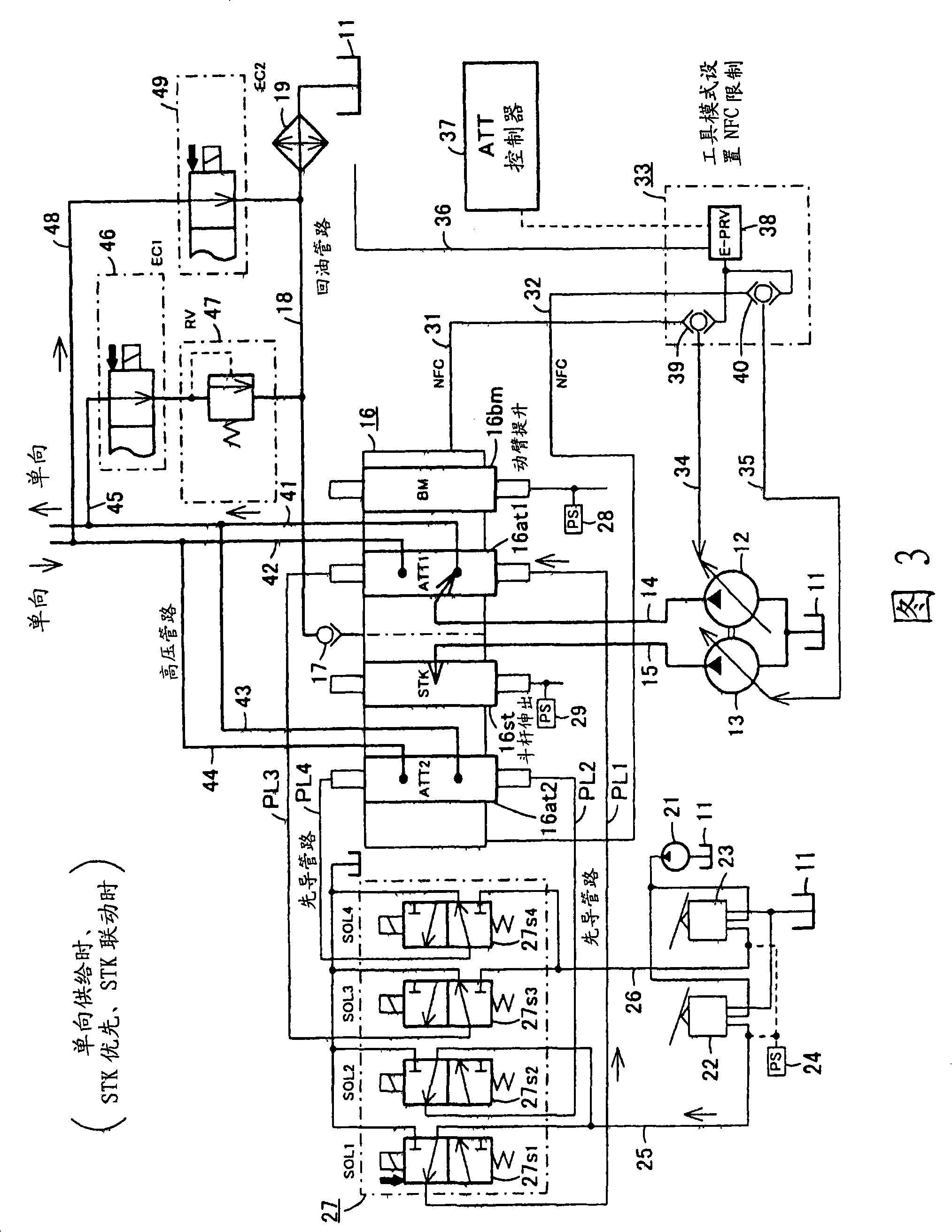

[0044] Referring to the first embodiment shown in FIGS. 1 to 7 , the second embodiment shown in FIG. 8 , and Figure 9 The work machine A shown illustrates the invention in detail.

[0045] Since it has been detailed Figure 9 The working machine A shown is omitted here. The boom 4 of the working device 3 of the working machine A is moved by the boom cylinder 4bm as the first actuator, and the arm 5 connected to the front end of the boom is moved by the boom cylinder 4bm as the first actuator. The arm cylinder 5st of the second actuator is operated, and the attachment 6 connected to the tip of the arm 5 is operated by the tool actuator 6at as a specific actuator.

[0046] Fig. 1 shows the first embodiment of the fluid pressure circuit, the suction port of the driving pump 12 as the first pump and the suction port of the idle pump 13 as the second pump are respectively connected on the oil tank 11 containing the working fluid (ie working oil). The drive pump 12 is directly driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com