Non-aqueous electrolyte secondary cell, manufacturing method thereof, and mounting method thereof

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte storage battery, electrolyte storage battery manufacturing, secondary battery, etc., can solve the problems of time-consuming processing, difficulty, difficult to use manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

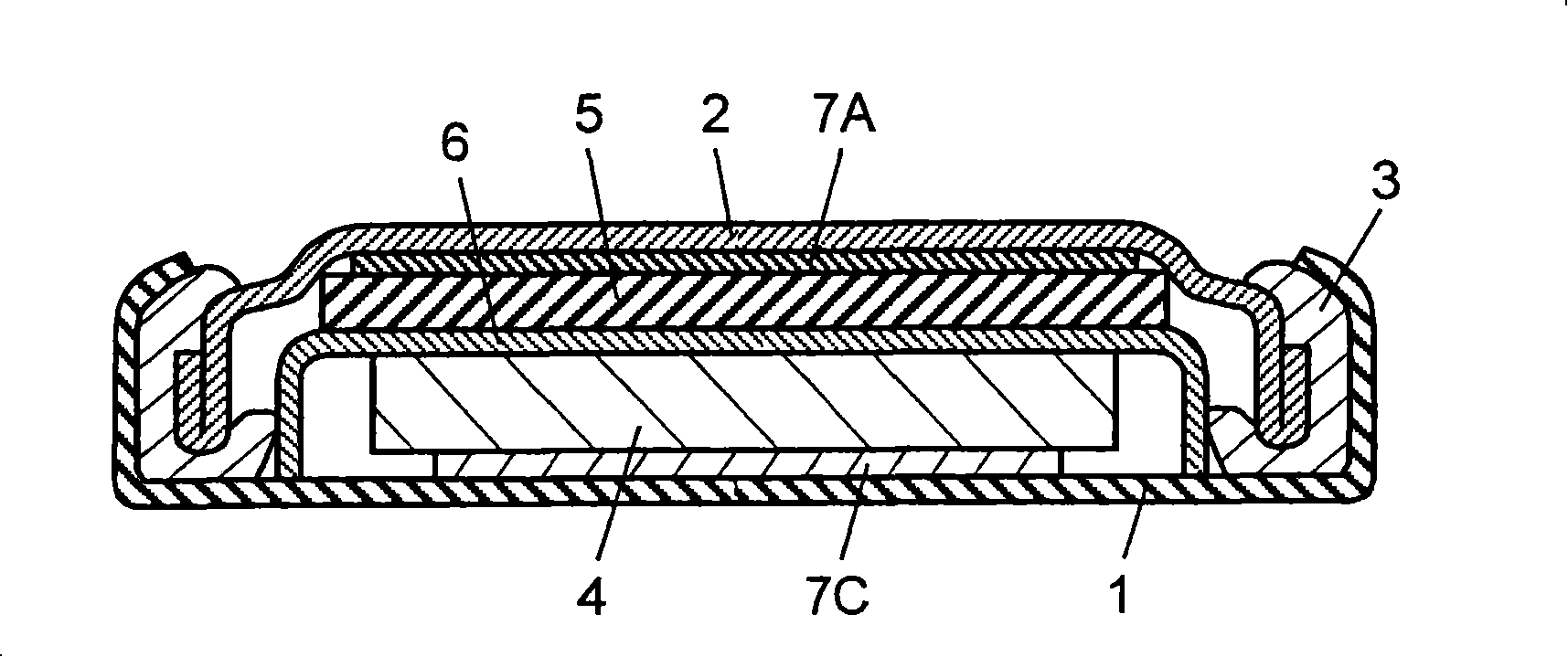

[0044] Hereinafter, preferred embodiments of the present invention will be described. First, display the figure 1 Ni / SUS304 / A1 aluminum alloy plate was used for the positive electrode can 1 in the coin-type battery, and SUS316 was used for the negative electrode can 2, and the results of various active materials were studied. Hereinafter, the procedure for producing the battery A will be described first.

[0045] Mix LiNO at a molar ratio of 1:3 3 with MnO 2 , after pre-sintering at 260°C for 5 hours, and then sintering at 340°C for 5 hours to prepare lithiated lanthanum manganese oxide. Then, the aforementioned oxide was mixed with carbon black as a conductive agent and PTFE as a binder to prepare an electrode mixture. In addition, the mixing ratio was a ratio of 88:5:7 by weight. The aforementioned electrode mixture was mixed at 2 ton / cm 2 After forming into pellets with a diameter of 10 mm under pressure, they were dried in the air at 250° C. to prepare positive elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com