Tibia endoprosthesis

A tibial and prosthesis technology, applied in the field of knee joint prosthesis, can solve the problem of not limiting the rearward displacement distance of the tibial pad, limiting the front-to-back translation distance of the tibial pad, and failing to ensure that the anterior side of the tibial pad is not lifted, etc. problems, to speed up the recovery time, ensure the stability of movement, and avoid the effect of dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

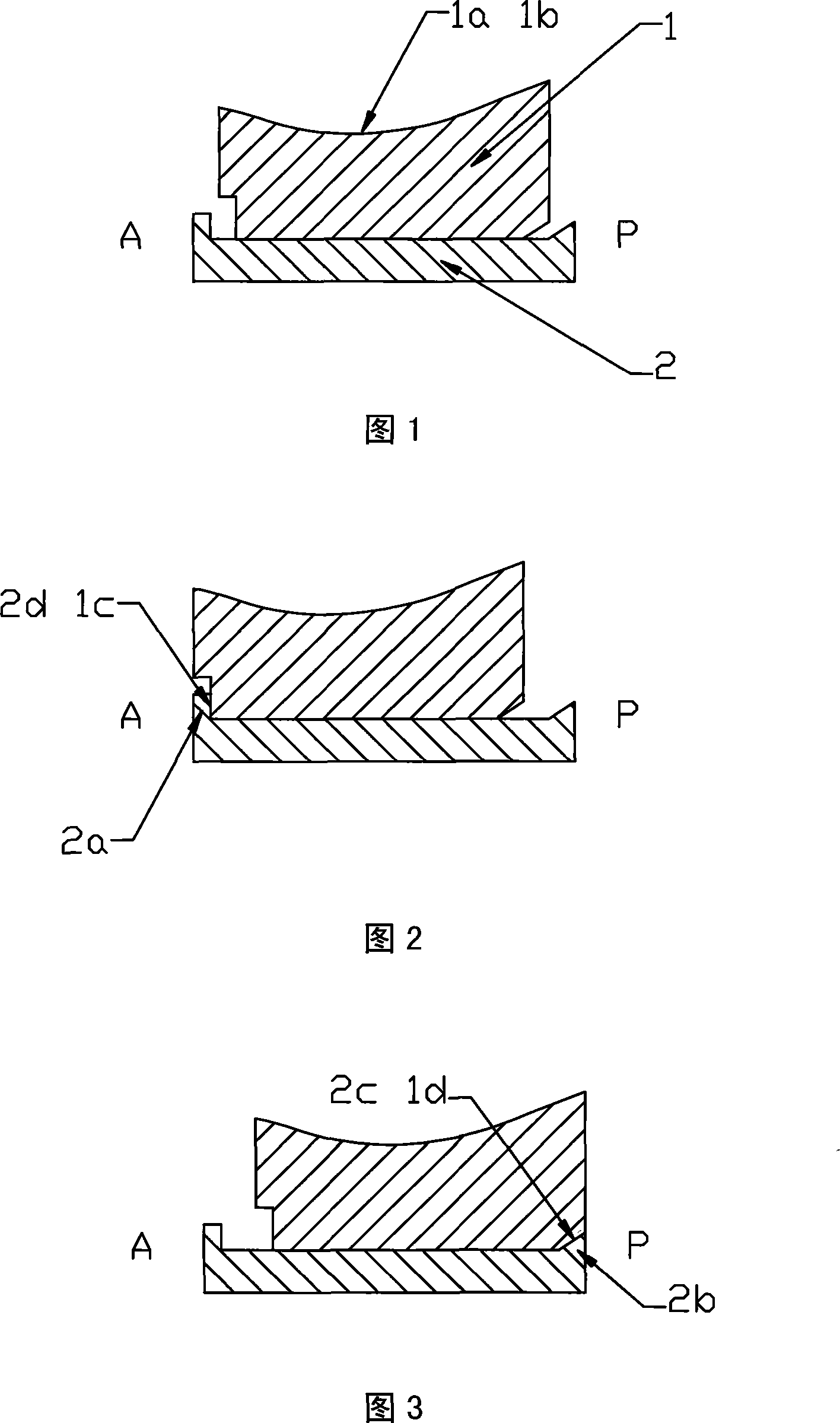

[0019] In Figure 1, Figure 2 and Figure 3, the tibial abutment 2 is connected to the proximal end of the tibia through the tibial mounting stem (not shown in the figure) or bone cement, and the tibial liner 1 is placed on the femoral prosthesis (not shown in the figure) Between the tibial bearing 2 and the tibial bearing 2, the tibial liner 1 can translate along the A-P direction (anterior-posterior direction) on the tibial bearing 2. Simulate the normal human natural knee joint movement process.

[0020] In FIG. 1 , the knee joint is in a fully extended knee position. At this time, the tibial pad 1 is in a free state along the A-P direction (anterior-posterior direction) on the tibial bearing 2 .

[0021] In Fig. 2, the knee joint is in a hyperextended position. At this time, the front positioning surface 1c of the tibial pad 1 is in contact with the inner surface 2d of the front positioning block 2a on the tibial bearing 2, so as to ensure that the forward movement distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com