Engine air valve controlling mechanism

A technology of engine valves and control mechanisms, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of many parts, complex structures, complex mechanisms, etc., to improve fuel economy and power, reduce mechanical Loss, optimize the effect of gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

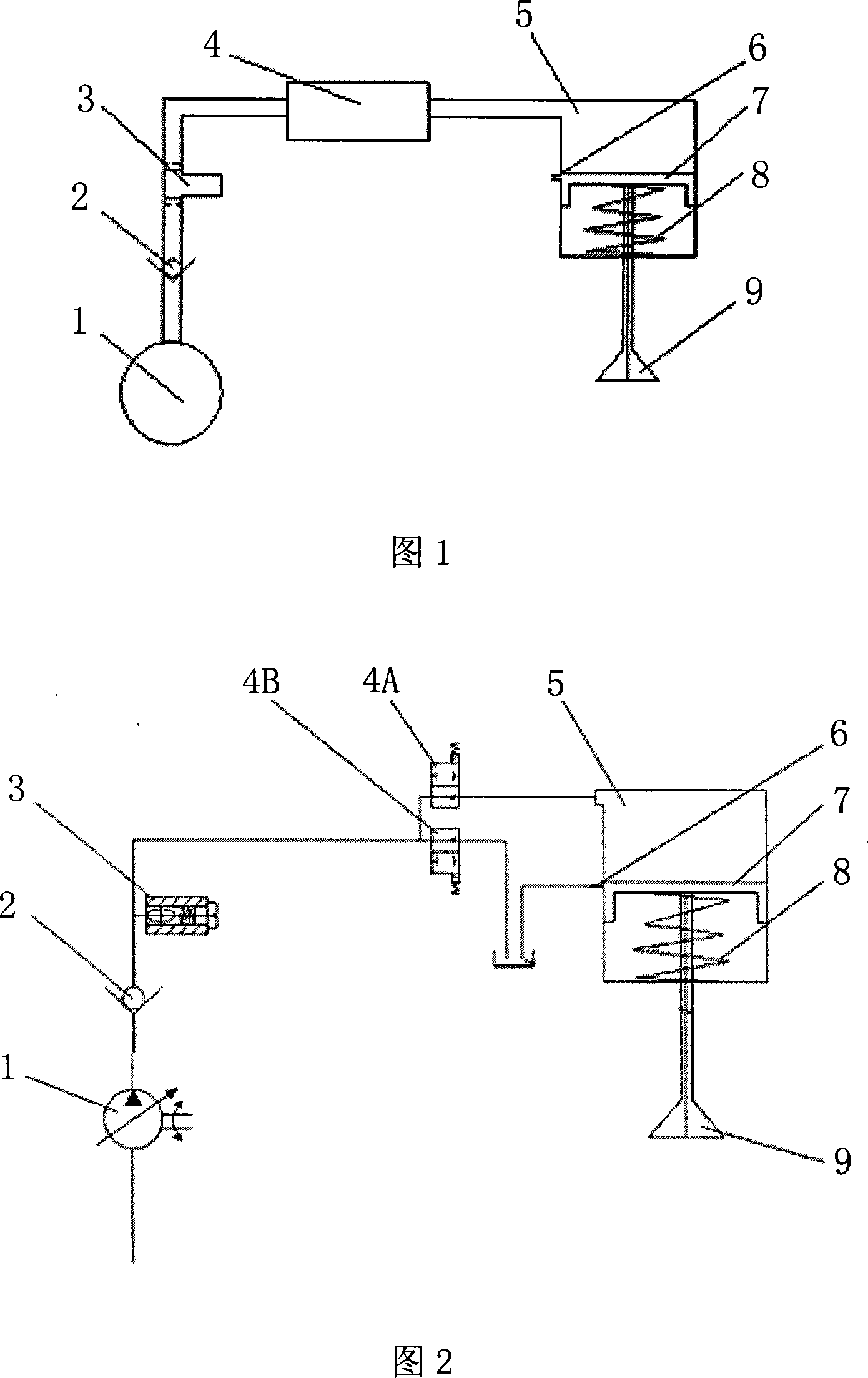

[0009] As shown in Fig. 1, 2, a kind of engine valve control mechanism, the present invention comprises the oil pump 1 that is driven by engine crankshaft, and the oil outlet end of oil pump 1 is provided with check valve 2, and the oil outlet end of check valve 2 and electromagnetic valve Or the oil inlet end of the electromagnetic valve group 4 is connected, and the oil outlet end of the electromagnetic valve or the electromagnetic valve group 4 is connected with the control device for controlling the valve lift and the oil tank respectively.

[0010] Since the engine speed has an influence on the speed of the oil pump, the pump oil volume is large when the speed is high, and the pump oil volume is small when the speed is low. The present invention utilizes this relationship to drive and control the oil pumped by the oil pump through the solenoid valve or solenoid valve group 4 Valve lift control device, this control device cooperates with the opening and closing of the solen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com