Agricultural material dynamic characteristic test apparatus and method

A technology for mechanical properties and test devices, which is applied in measurement devices, strength properties, scientific instruments, etc., can solve the problems of inappropriate structure, significant differences in engineering materials, technical parameters and sensor accuracy cannot meet the measurement requirements, and achieve accurate experimental, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

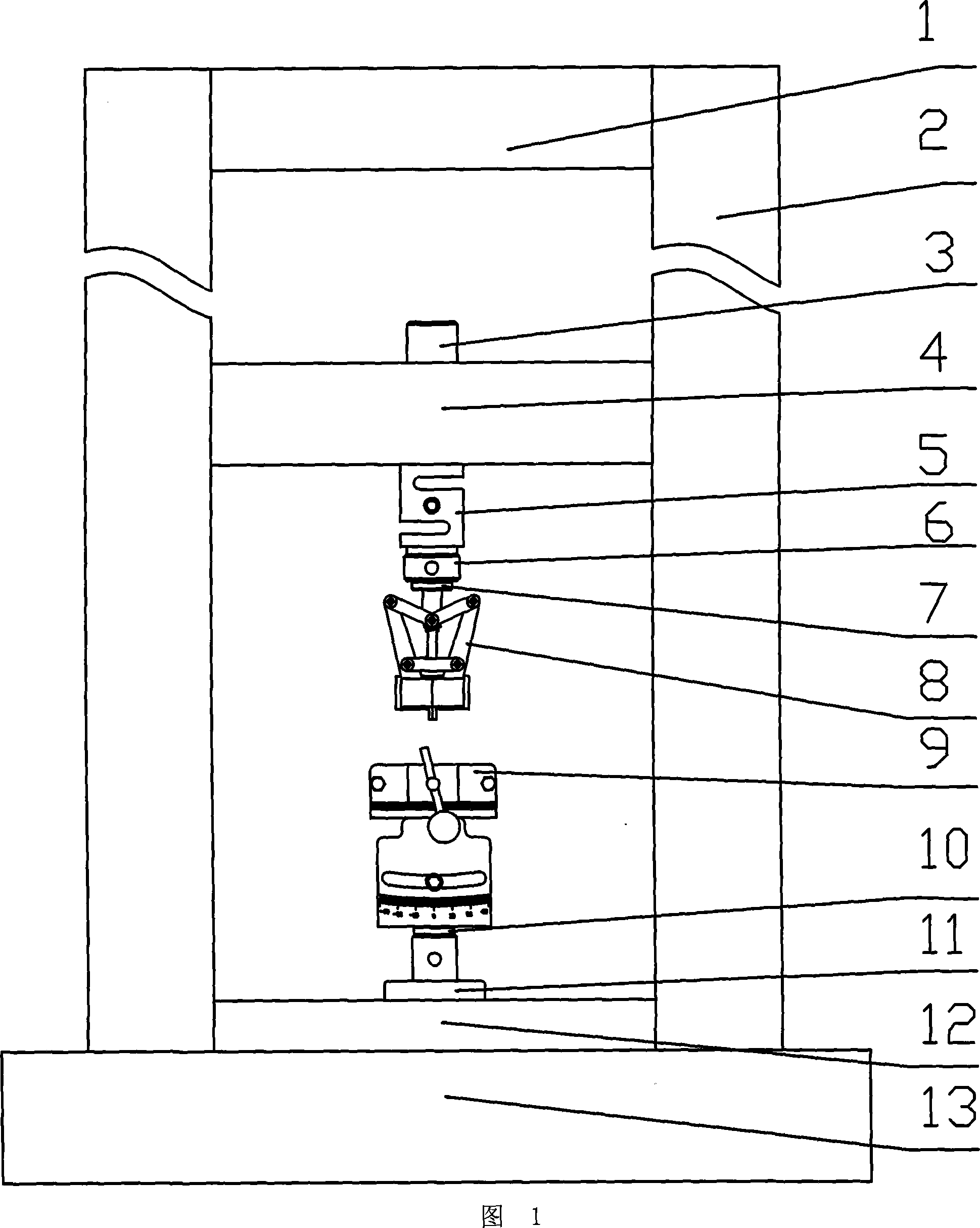

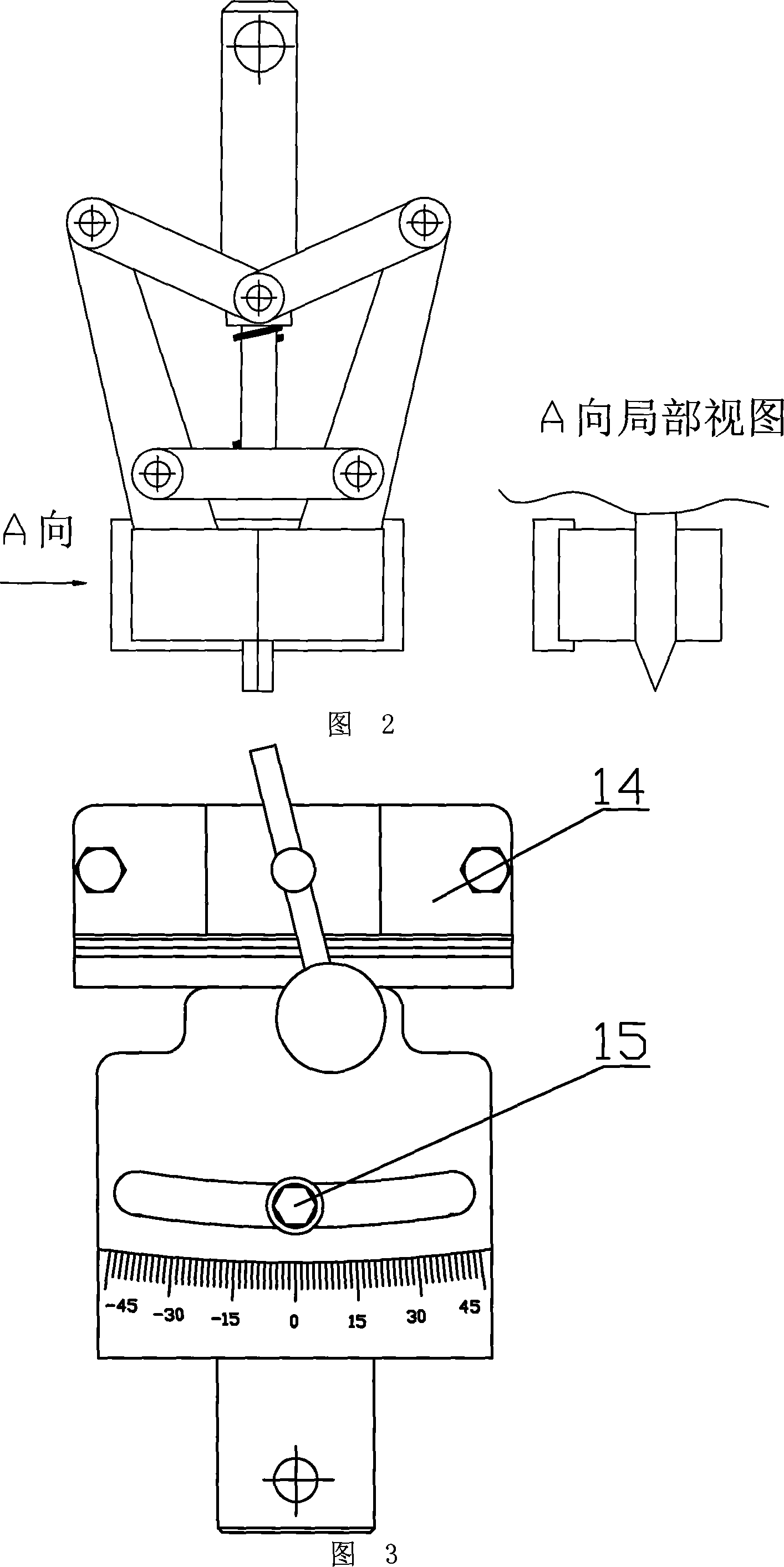

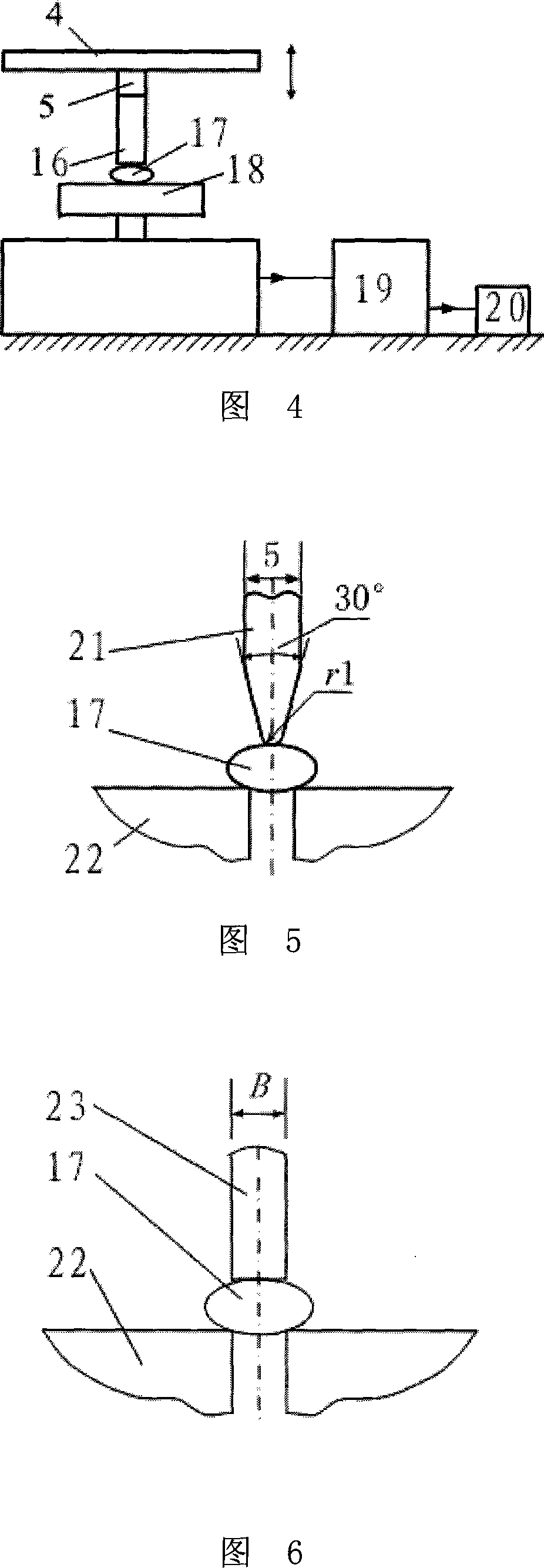

[0024] As shown in Figure 1, the left and right brackets 2 are erected on the left and right sides of the base 13, and the uppermost crossbeam 1 above the left and right brackets 2 is fixedly connected. On the lower crossbeam 12, the moving crossbeam 4 is installed between the upper crossbeam 1 and the lower crossbeam 12 and connected with the left and right brackets 2 to form a base frame. The moving beam 4 can move up and down in the left and right brackets 2 to obtain stretching and compression strokes, and the stroke is controlled by the upper and lower limit blocks; the force sensor 5 is installed on the moving beam 4 through the sensor connecting rod 3, and then the pin 7 and the upper joint 6 connect the upper chuck 8 with the force sensor 5; the force sensor 5 adopts a small-range, high-precision sensor, and its test force measurement range is 2 to 500N, and the measurement accuracy is ±0.5% of the indicated value , the resolution is 1 / 240000. To replace the collet, y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com