LCD device, photoelectric device and process for production thereof

A liquid crystal display device and liquid crystal display panel technology, applied in light guides, optics, optical components, etc., can solve the problems of flexible substrates that are easily deformed, affect the display quality of the display, and cannot fully support the display medium, and achieve the effect of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

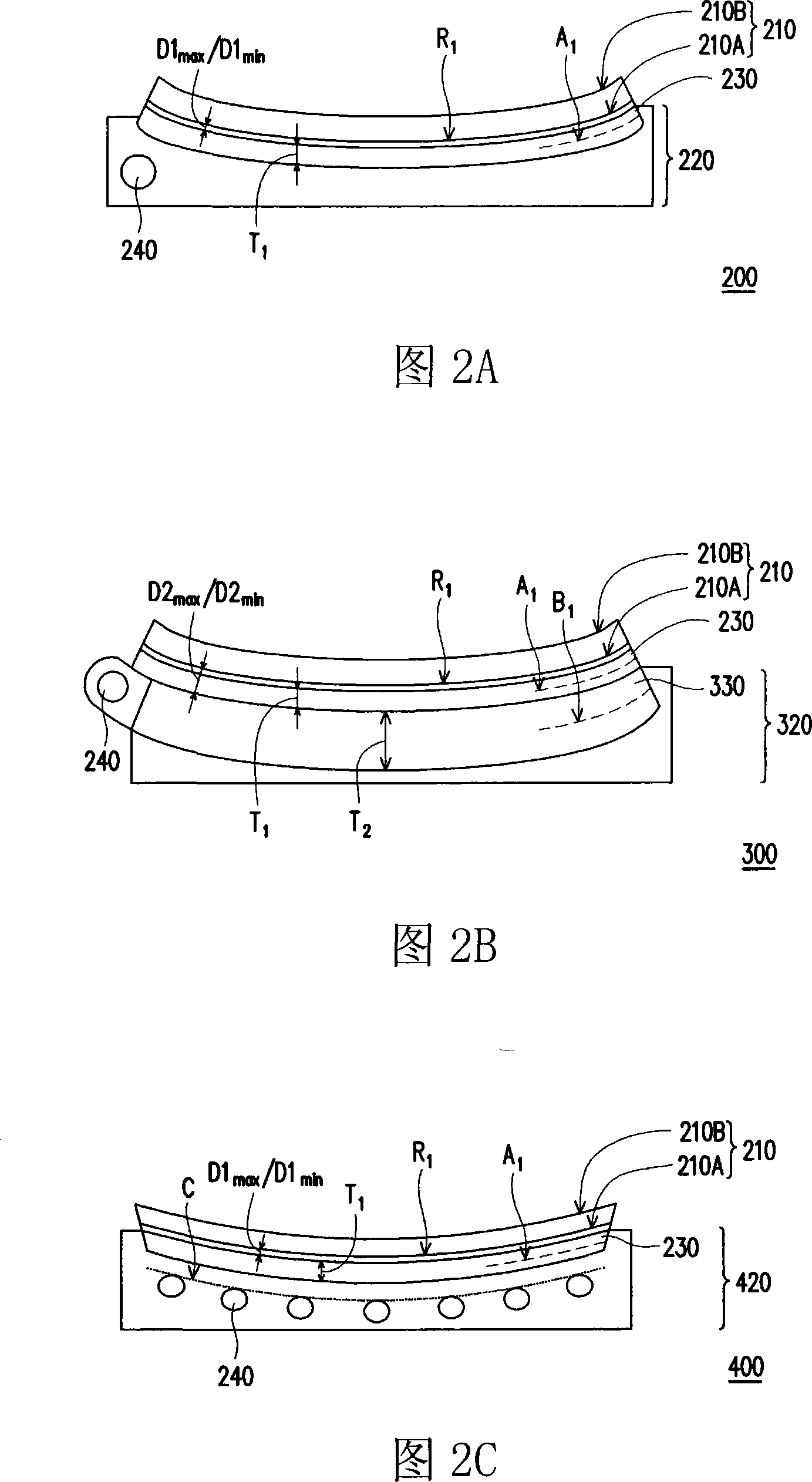

[0061] FIG. 2A is a schematic diagram of a liquid crystal display device of the present invention. Please refer to FIG. 2A , the liquid crystal display device 200 includes a curved liquid crystal display panel 210 and a backlight module 220 . The curved LCD panel 210 has an inner curved surface 210A and an outer curved surface 210B. As shown in FIG. 2A , the outer curved surface 210B is concave. The backlight module 220 is disposed on the inner curved surface 210A of the curved liquid crystal display panel 210, and the backlight module 220 has a curved optical film 230 and a light source 240, wherein the bending degree of the curved optical film 230 and the curved liquid crystal display panel 210 are substantially the same, here It should be noted that when the shortest distance from any point on the curved optical film 230 to the curved liquid crystal display panel 210 is substantially the same, it is defined as the same degree of curvature. In addition, the curved optical ...

no. 2 example

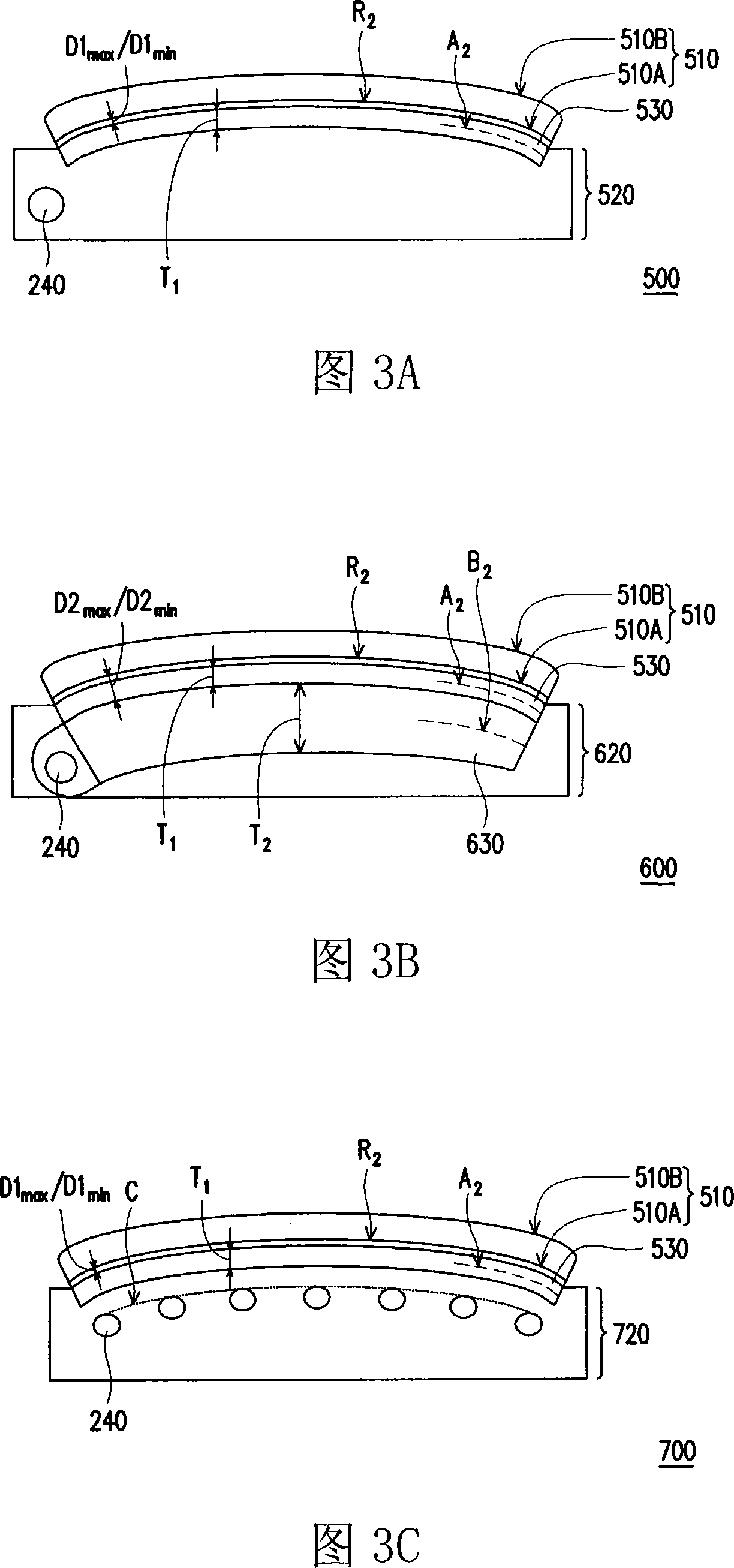

[0070] FIG. 3A is a schematic diagram of a liquid crystal display device of the present invention. Referring to FIG. 3A , the liquid crystal display device 500 includes a curved liquid crystal display panel 510 and a backlight module 520 . The curved LCD panel 510 has an inner curved surface 510A and an outer curved surface 510B. As shown in FIG. 3A , the outer curved surface 510B is convex. The backlight module 520 is disposed on the inner curved surface 510A of the curved liquid crystal display panel 510, and the backlight module 520 has a curved optical film 530 and a light source 240, wherein the bending degree of the curved optical film 530 and the curved liquid crystal display panel 510 are substantially the same, here It should be noted that when the shortest distance from any point on the curved optical film 530 to the curved liquid crystal display panel 510 is substantially the same, it is defined as the same degree of curvature.

[0071] Specifically, the thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com