Moisture-proof structure for optoelectronic device and preparation method of moisture-proof structure

A technology for optoelectronic devices and electronic devices, applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, nanotechnology for materials and surface science, etc. and other problems, to achieve the effect of increasing the distribution range and quantity, avoiding environmental pollution, and increasing working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

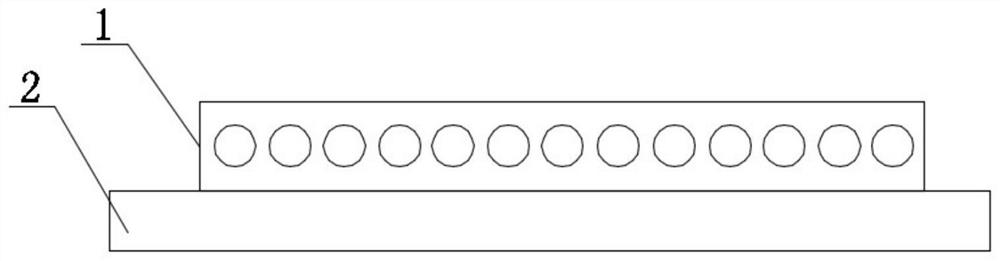

[0035] Such as figure 1 As shown, the moisture-proof film that can be used for optoelectronic devices has a total thickness of 15 μm, and the mixed solvent is ethylene glycol, polymer polyelectrolyte type 731 dispersant, silane coupling agent YGO-1204 and aqueous emulsion. These four components The ratio is: 1:1:1:1; the moisture-proof agent is applied by roller coating, LB film method, scraping coating, spin coating, drop coating, spray coating, pulling method, casting method, dip coating, inkjet printing, self-assembly Or have a stable film structure after screen printing treatment, a mixture of 20% weeping willow root extract and glycerin with larger contact area and green environmental protection characteristics, and the protective agent is nano-scale porous SiO with ethylene glycol as a solvent 2 particles. The ingredients are as follows:

[0036] Mixed solvent: 65%, moisture-proof agent: 25%, protective agent: 10%;

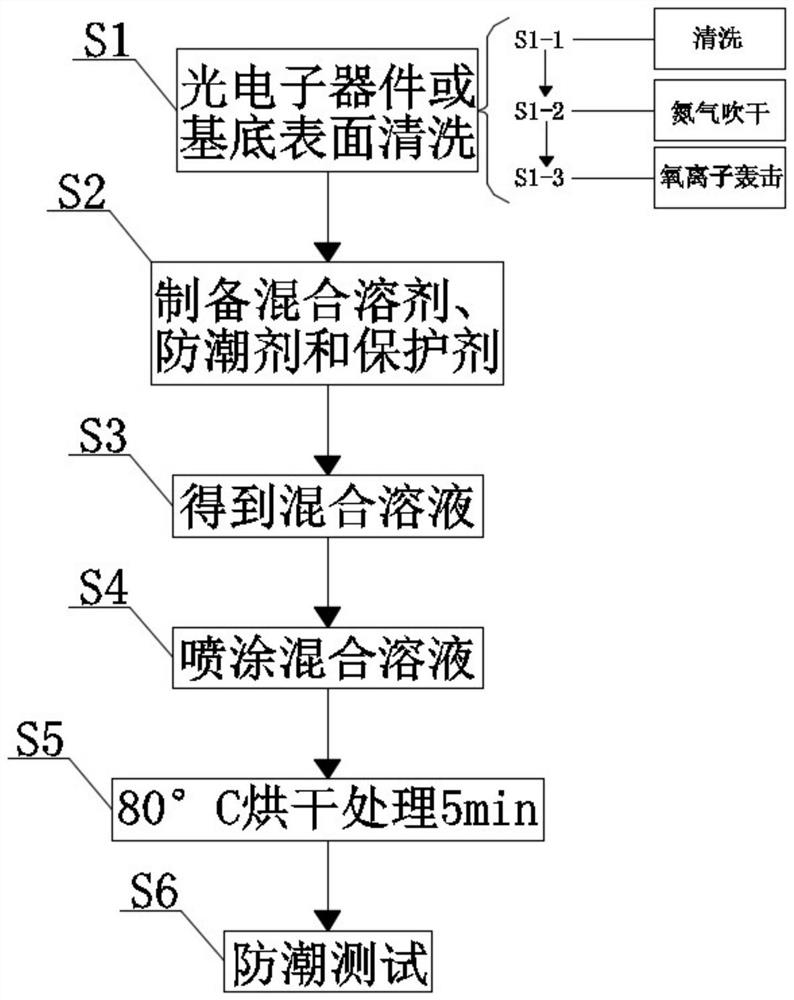

[0037] The preparation method is as follows:

[00...

Embodiment 2

[0043] Such as figure 1As shown, the moisture-proof film that can be used for optoelectronic devices has a total thickness of 15 μm, and the mixed solvent is ethylene glycol, polymer polyelectrolyte type 731 dispersant, silane coupling agent YGO-1204 and aqueous emulsion. These four components The ratio is: 1:1:1:1; the moisture-proof agent is applied by roller coating, LB film method, scraping coating, spin coating, drop coating, spray coating, pulling method, casting method, dip coating, inkjet printing, self-assembly Or have a stable film structure after screen printing treatment, a mixture of 20% weeping willow root extract and glycerin with larger contact area and green environmental protection characteristics, and the protective agent is nano-scale porous SiO with ethylene glycol as a solvent 2 particles. The ingredients are as follows:

[0044] Mixed solvent 65%, moisture-proof agent 20%, protective agent 15%;

[0045] The preparation method is as follows:

[0046] ...

Embodiment 3

[0051] Such as figure 1 As shown, the moisture-proof film that can be used for optoelectronic devices has a total thickness of 15 μm, and the mixed solvent is ethylene glycol, polymer polyelectrolyte type 731 dispersant, silane coupling agent YGO-1204 and aqueous emulsion. These four components The ratio is: 1:1:1:1; the moisture-proof agent is applied by roller coating, LB film method, scraping coating, spin coating, drop coating, spray coating, pulling method, casting method, dip coating, inkjet printing, self-assembly Or have a stable film structure after screen printing treatment, a mixture of 20% weeping willow root extract and glycerin with larger contact area and green environmental protection characteristics, and the protective agent is nano-scale porous SiO with ethylene glycol as a solvent 2 particles. The ingredients are as follows:

[0052] Mixed solvent 60%, moisture-proof agent 25%, protective agent 15%;

[0053] The preparation method is as follows:

[0054]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com