Anti-ultraviolet radiation thin film material and anti-ultraviolet radiation thin film for optoelectronic device and preparation method of anti-ultraviolet radiation thin film

A technology for anti-ultraviolet radiation and optoelectronic devices, which is applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of insufficient stability and lasting thickness of anti-ultraviolet radiation films, improve the efficiency of anti-ultraviolet radiation, increase the distribution range and quantity, The effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

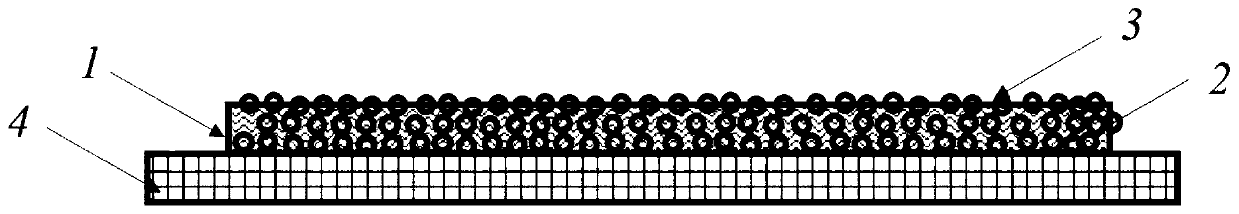

Image

Examples

Embodiment 1

[0038] The anti-ultraviolet radiation film material that can be used in optoelectronic devices, the composition is as follows:

[0039] Mixed solvent 60%,

[0040] UV protection agent 25%,

[0041] Porous Protectant 15%,

[0042] Wherein, the mixed solvent is a mixture of 35% ethylene glycol, 35% polymer polyelectrolyte type 731 dispersant, 15% silane coupling agent YGO-1204 and 15% of 20% water-based acrylic resin emulsion, and the anti-ultraviolet radiation agent is 30% A mixture of % weathering wood oil solution and 70% glycerin, the porous protective agent is nanoporous SiO with ethylene glycol as solvent 2 Granular, nanoporous SiO 2 The mass / volume ratio of particles and ethylene glycol is 40g / mL, and the nanoporous SiO 2 The particle size of the particles is 20-50 nm.

[0043] The preparation method of the anti-ultraviolet radiation film that can be used for optoelectronic device is as follows:

[0044] (1) First clean the optoelectronic device or the surface substra...

Embodiment 2

[0048] The anti-ultraviolet radiation film material that can be used in optoelectronic devices, the composition is as follows:

[0049] Mixed solvent 57%,

[0050] UV protection agent 28%,

[0051] Porous Protectant 15%,

[0052] Wherein, the mixed solvent is a mixture of 35% ethylene glycol, 35% polymer polyelectrolyte type 731 dispersant, 15% silane coupling agent YGO-1204 and 15% of 20% water-based acrylic resin emulsion, and the anti-ultraviolet radiation agent is 30% A mixture of % weathering wood oil solution and 70% glycerin, the porous protective agent is nanoporous SiO with ethylene glycol as solvent 2 Granular, nanoporous SiO 2 The mass / volume ratio of particles and ethylene glycol is 40g / mL, and the nanoporous SiO 2 The particle size of the particles is 20-50 nm.

[0053] The preparation method of the anti-ultraviolet radiation film that can be used for optoelectronic device is as follows:

[0054] (1) First clean the optoelectronic device or the surface subst...

Embodiment 3

[0058] The anti-ultraviolet radiation film material that can be used in optoelectronic devices, the composition is as follows:

[0059] Mixed solvent 55%,

[0060] UV protection agent 30%,

[0061] Porous Protectant 15%,

[0062] Wherein, the mixed solvent is a mixture of 35% ethylene glycol, 35% polymer polyelectrolyte type 731 dispersant, 15% silane coupling agent YGO-1204 and 15% of 20% water-based acrylic resin emulsion, and the anti-ultraviolet radiation agent is 30% A mixture of % weathering wood oil solution and 70% glycerin, the porous protective agent is nanoporous SiO with ethylene glycol as solvent 2 Granular, nanoporous SiO 2 The mass / volume ratio of particles and ethylene glycol is 40g / mL, and the nanoporous SiO 2 The particle size of the particles is 20-50 nm.

[0063] The preparation method of the anti-ultraviolet radiation film that can be used for optoelectronic device is as follows:

[0064] (1) First clean the optoelectronic device or the surface subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com