Automatic meat floss machine

An automatic technology for frying and loosening machines, applied in baking, food preparation, food science, etc., can solve the problems of uneven heating and the failure of artificial intelligence in frying and loosening machines, and achieve uniform heating, high product quality, and artificial intelligence high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

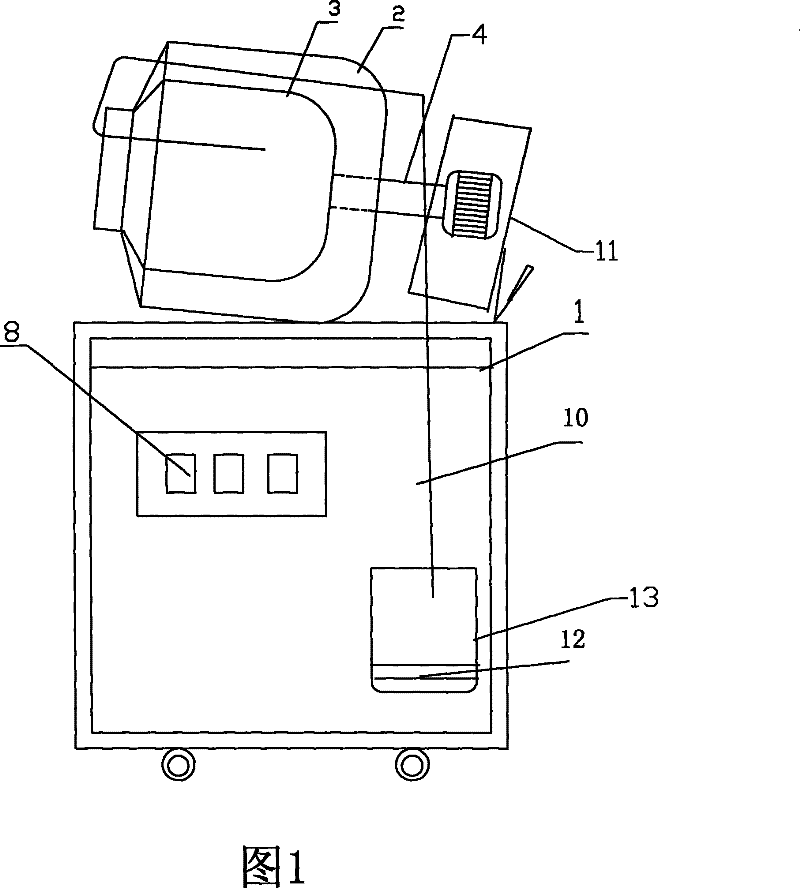

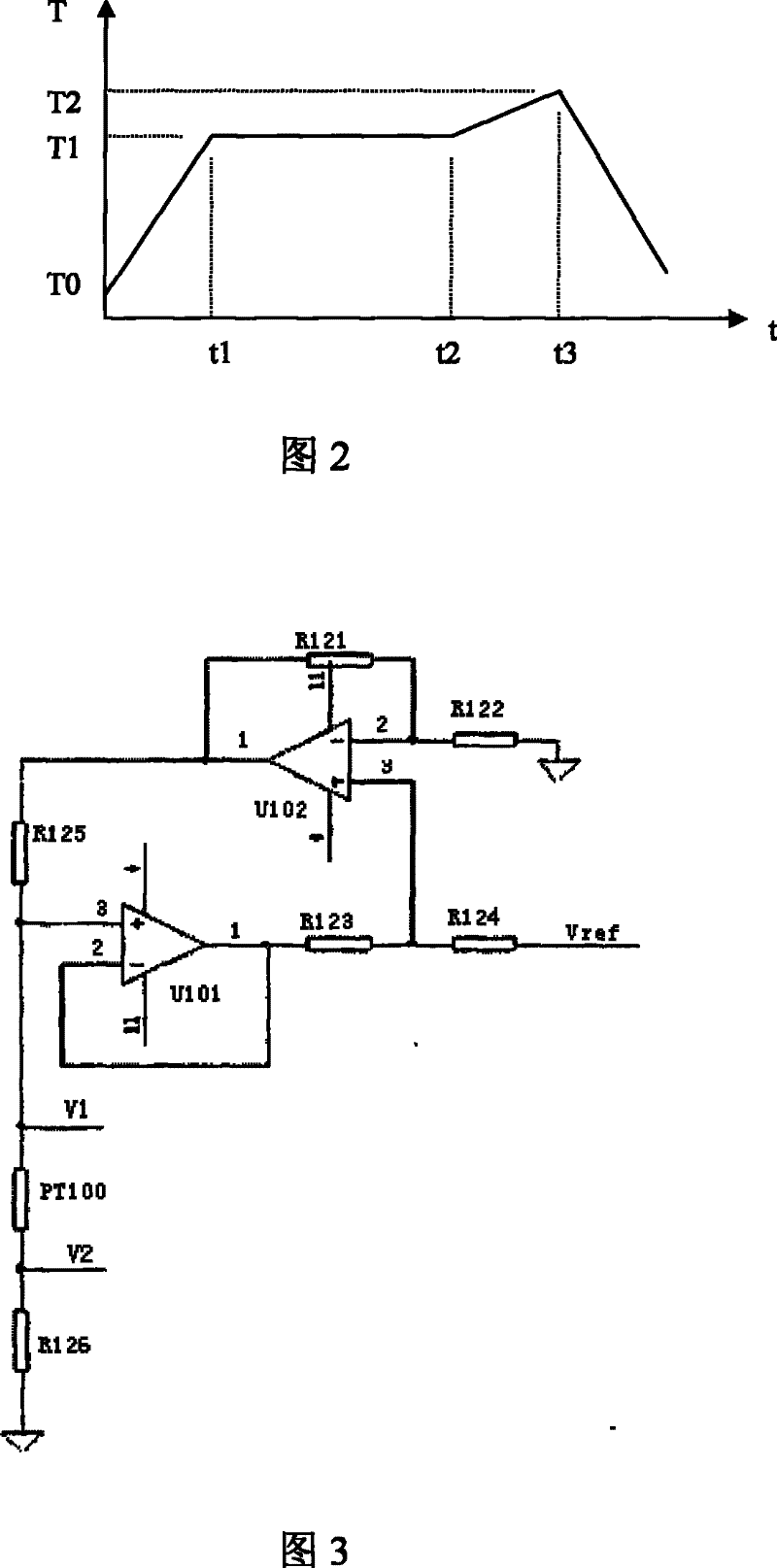

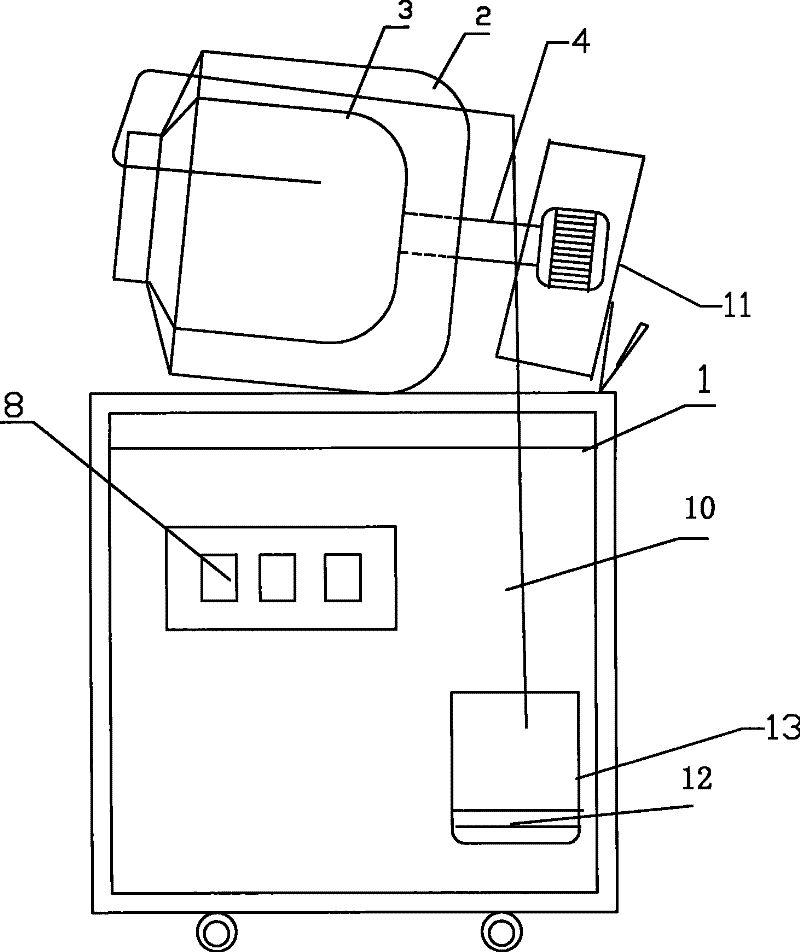

[0013] refer to Figure 1-3 : an automatic stir frying machine, comprising a frame 1, a cylinder 2 is arranged on the frame 1, specifically, the rear end of the cylinder 2 is connected with an organic base 11, and the base 11 is installed on the frame 1 through a bearing, and the cylinder The body 2 is covered with an inner tank 3, and the rotary shaft 4 of the inner tank 3 is connected to the drive motor through a reducer; the electric heating device is arranged in the interlayer between the cylinder body 2 and the inner tank 3, and the interlayer is equipped with a device in contact with the inner tank. The first brush and the second brush, the electric heating device is in thermal contact with the inner tank 3 through the first brush, and the second brush is connected to a signal input terminal of a temperature sensor, The temperature sensor measures the real-time temperature of the inner tank through the second electric brush; the automatic stir-frying machine of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com