Method and apparatus for sorting electrostatic attraction type weight

An electrostatic attraction and weight separation technology, applied in electrostatic effect separation, chemical instruments and methods, solid separation, etc., can solve the problem that the sorting efficiency of the whole machine is difficult to meet the requirements of drug production, the detection efficiency of a single weight sensor is limited, and the high cost is known. The actual weight and other issues have achieved the effect of easy promotion, convenient use and maintenance, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

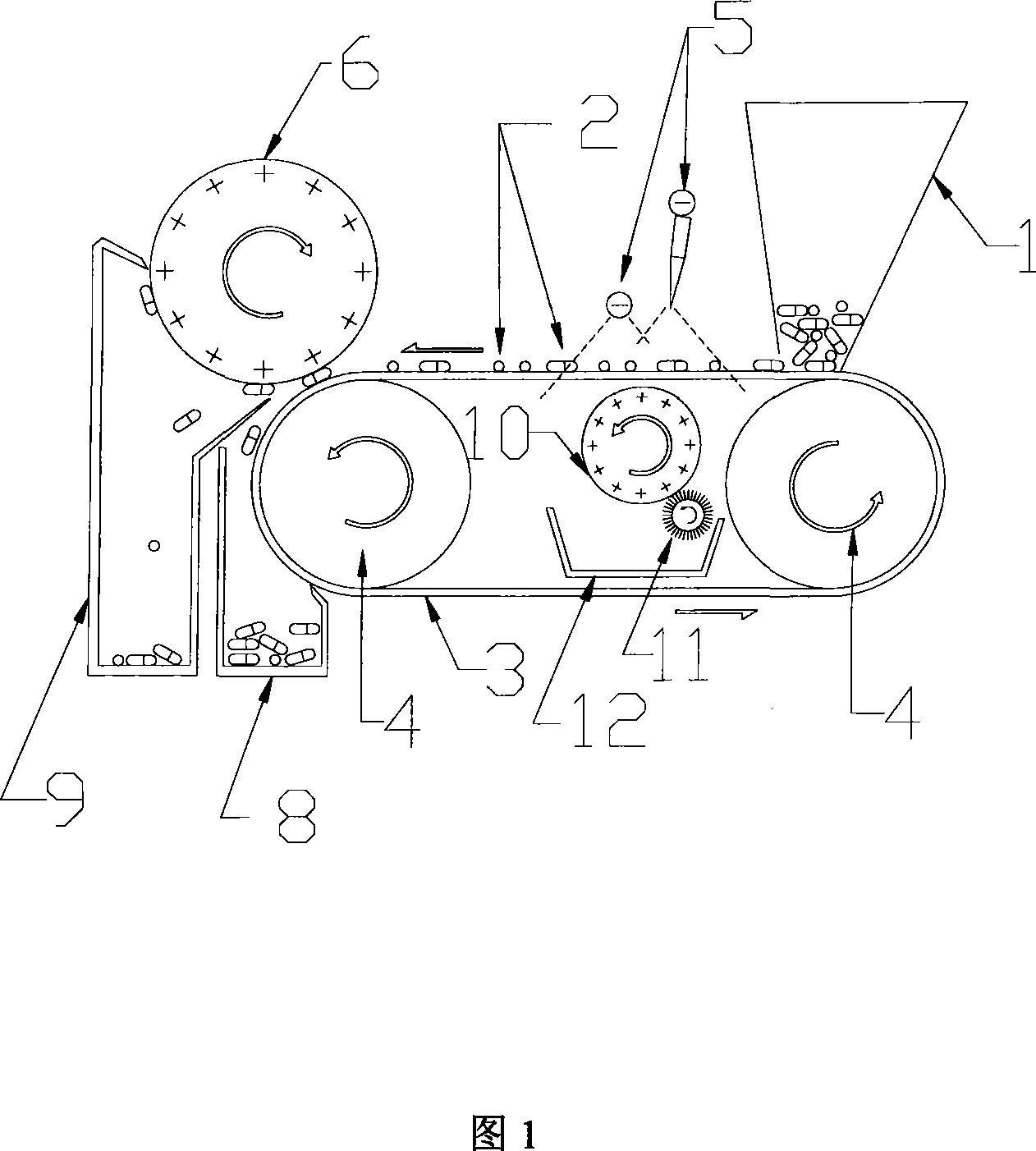

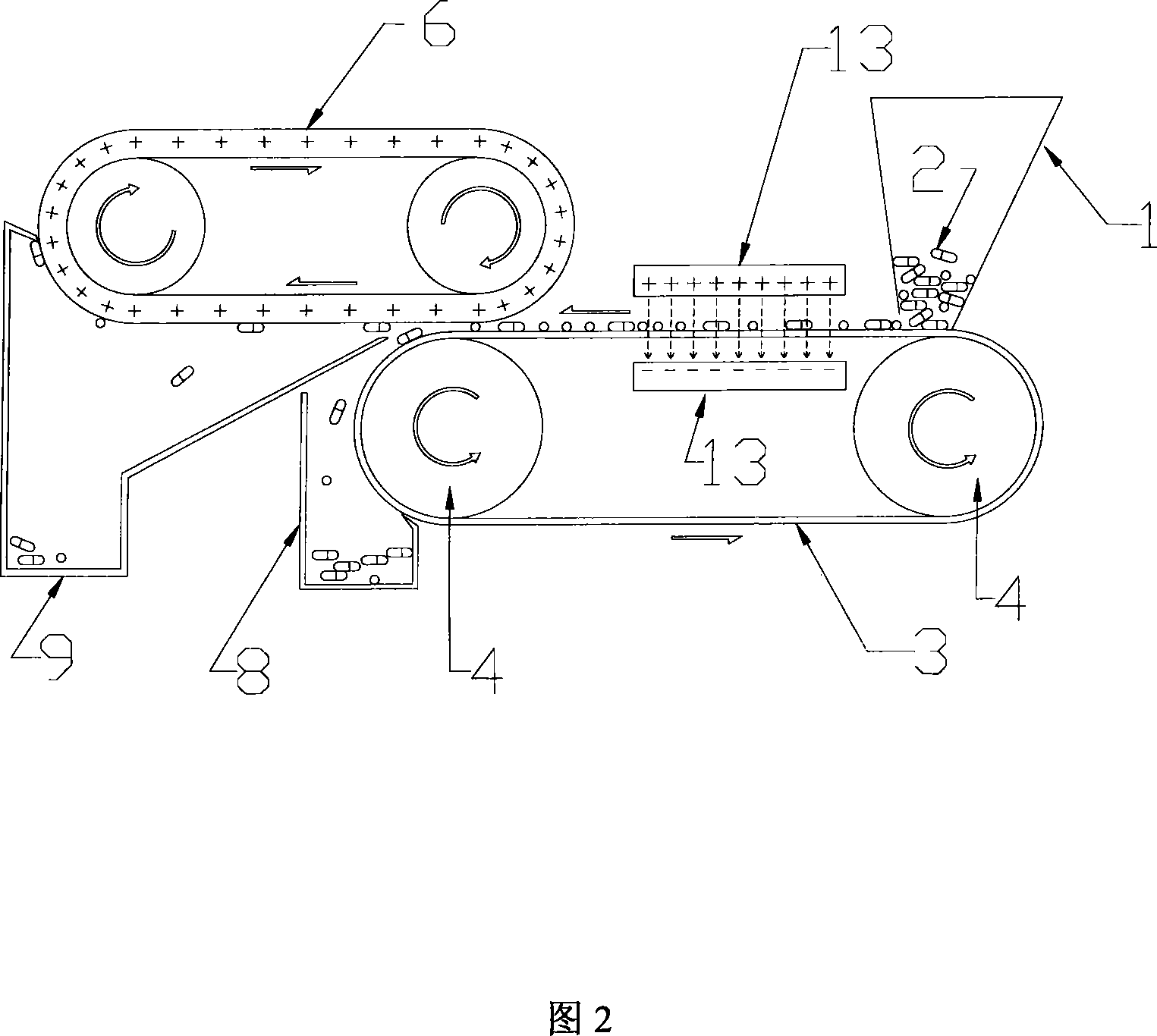

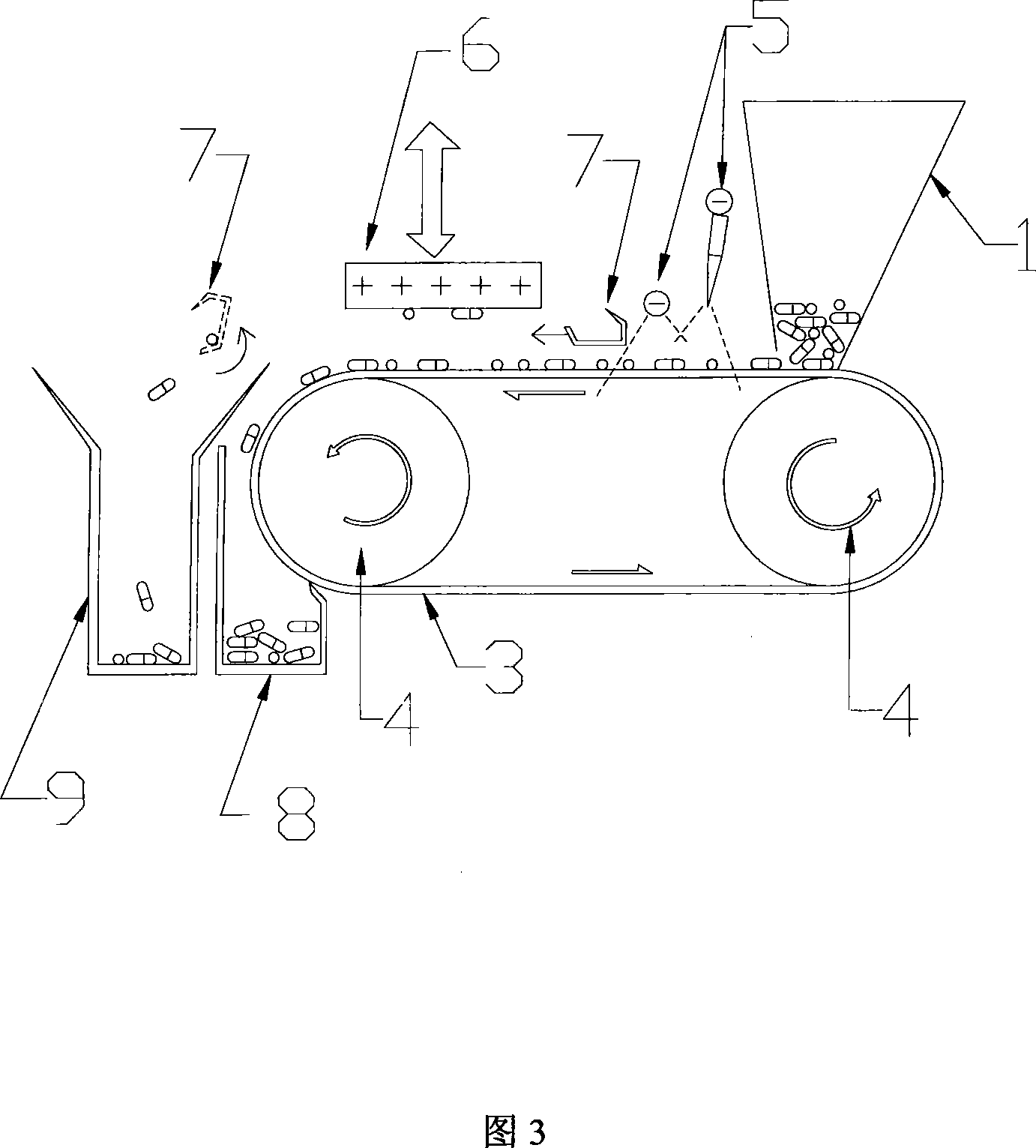

[0029] An electrostatic attraction weight sorting method, which makes the object to be sorted be charged with one kind of charge, and the sorting mechanism is charged with another kind of charge, so that the object to be sorted is close to the sorting mechanism, and when the sorting mechanism is located In the case of above the object, adjust the power carried by the sorting mechanism and the object to be sorted, and adjust the distance between the sorting mechanism and the object to be sorted, so that the attraction between them is just equal to the current sorting. The gravity value of the object to be sorted with a standard weight is used as the standard value of this sorting, and then the position of the sorting mechanism is fixed and the electricity carried by it is fixed, and each to be sorted The electricity carried by the objects is the same and fixed, so when the weight of an object to be sorted is less than the standard value of sorting, then the gravity it receives i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com