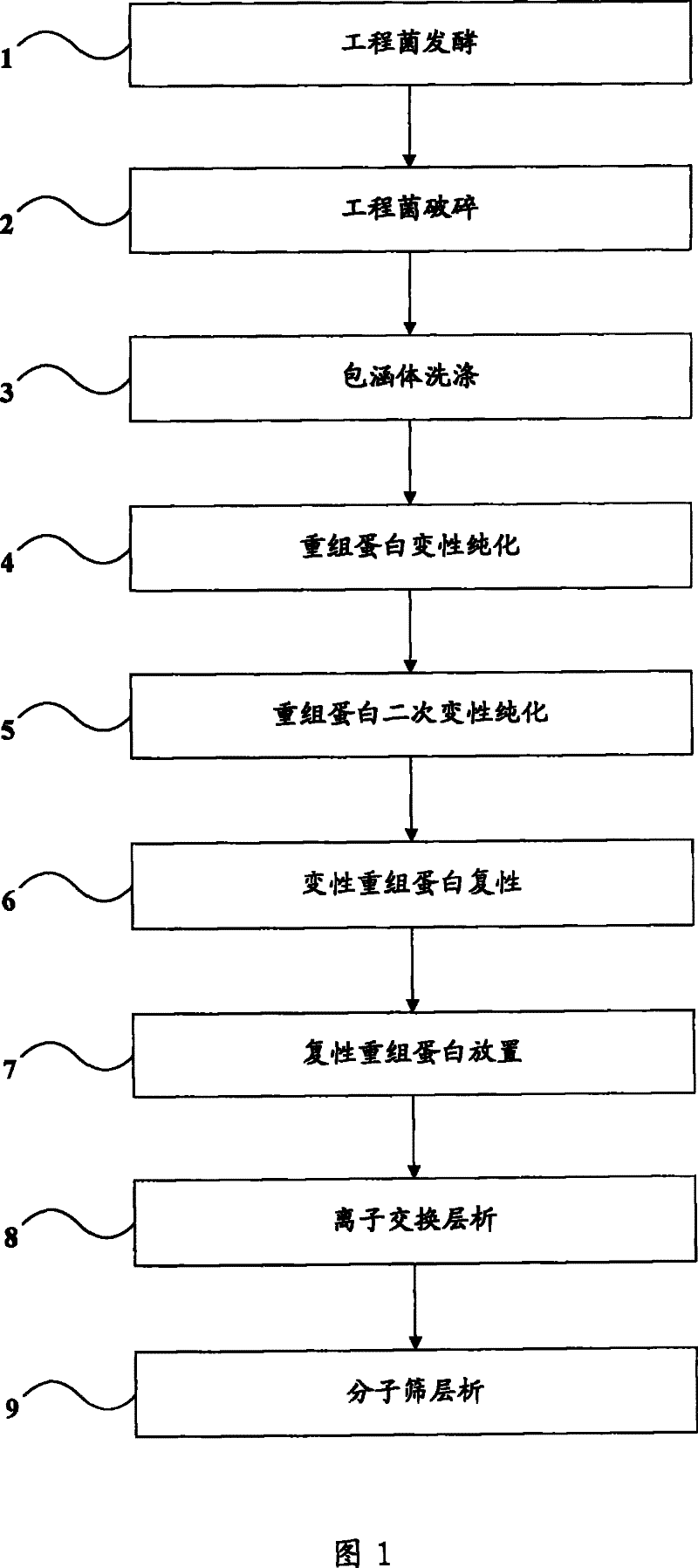

Extraction and purification process for recombinant protein

A technology of recombinant protein and purification method, applied in the field of biopharmaceuticals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

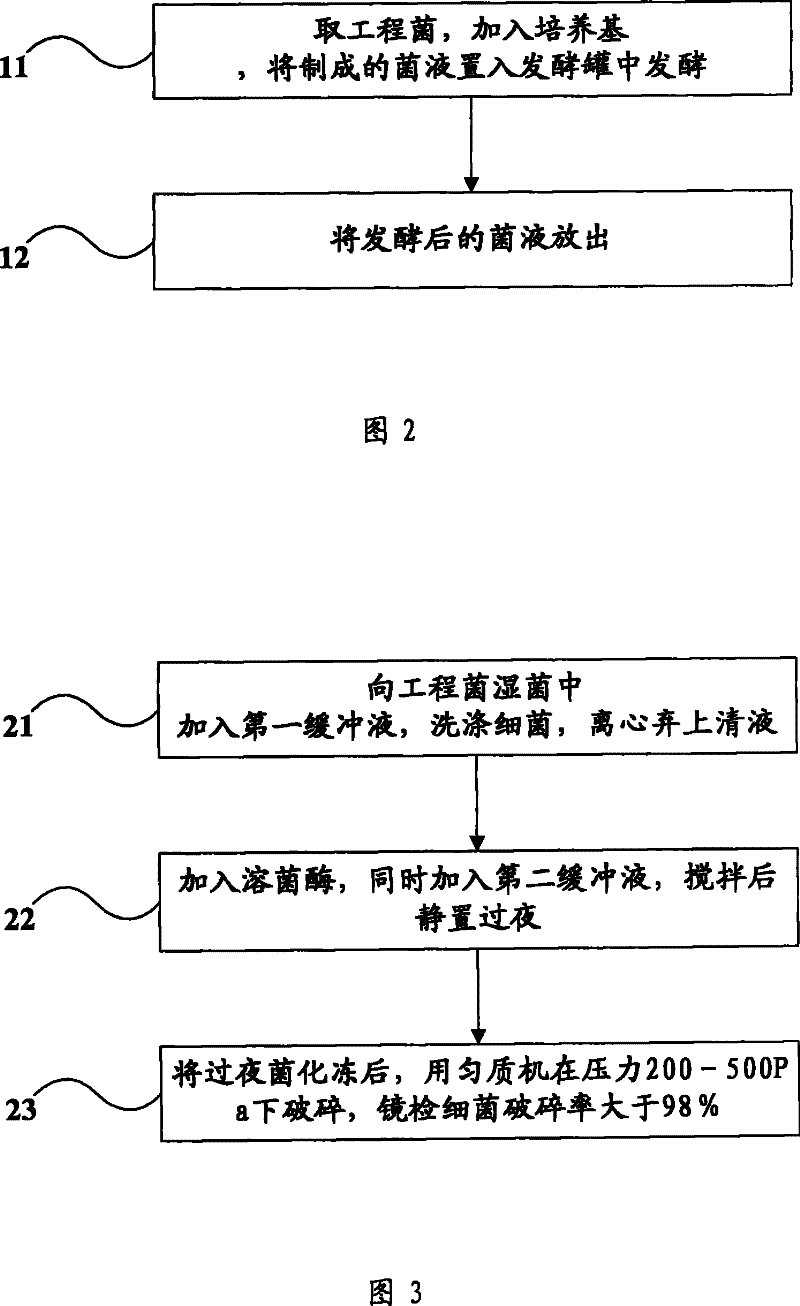

[0079] Step 101, get the engineering bacteria, carry out amplification with bacteriolysis broth medium (LB medium), put the engineering bacteria liquid of 10% of the fermentation volume into a fermenter containing high-density formula medium for fermentation, high-density formula The medium is 10g / L tryptone, 20g / L yeast extract, 12.5g / L hydrolase protein, 4g / L KH 2 PO 4 , 15g / L glucose;

[0080] Step 102, during the fermentation process, regularly and continuously drop increasing amounts of high-density formula culture medium;

[0081] Step 103, after 7.5 hours of fermentation, induce the engineered bacteria at a temperature of 42° C. for 3.5 hours, and release the fermented bacterial liquid from the fermenter after 11 hours of fermentation;

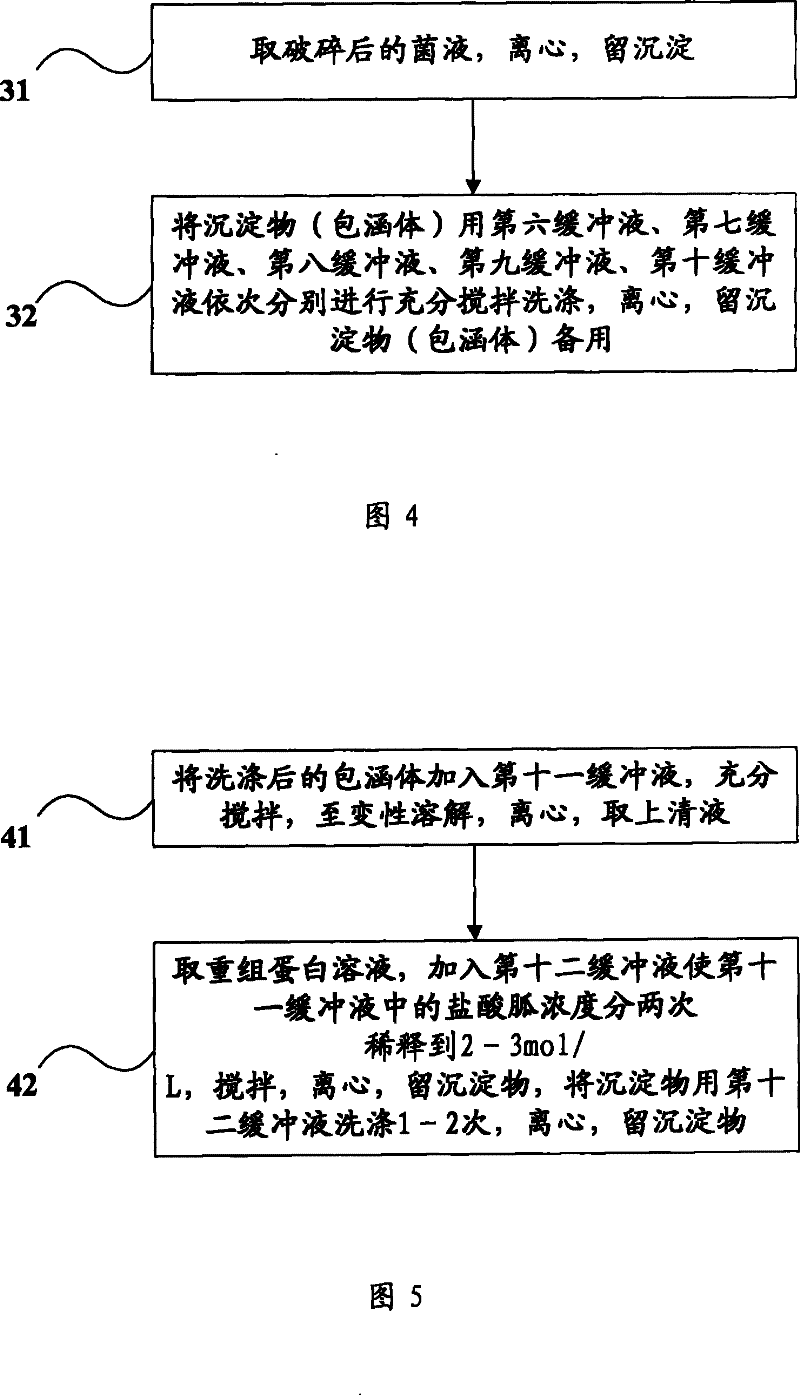

[0082] Step 104, take 100 g of engineering bacteria wet bacteria, add 1000 ml of the first buffer solution (20 mmol / LTris-HCl (tris-hydrochloric acid), pH 8.0), wash the bacteria, and centrifuge at 4 ° C for 10 minutes, Rotate at 700...

no. 2 example

[0099] Step 201, get engineering bacterium, after carrying out amplification with bacteriolysis broth culture medium (LB medium), insert the engineering bacterium of 10% by fermentation volume in the fermenter that contains high-density formula medium to carry out fermentation; High-density formula The medium is 5g / L tryptone, 15g / L yeast extract, 7.5g / L hydrolase protein, 1g / L KH 2 PO 4 , 10g / L glucose;

[0100] Step 202, during the fermentation process, regularly and continuously drop increasing amounts of high-density formula culture medium;

[0101] Step 203, after 8 hours of fermentation, inducing the engineered bacteria at a temperature of 42°C for 3 hours, and releasing the fermented bacterial liquid from the fermenter after 11 hours of fermentation;

[0102] Step 204, take 100 g of engineering bacteria wet bacteria, add 500 ml of the first buffer solution (20 mmol / LTris-HCl (tris-hydrochloric acid), pH 8.0), wash the bacteria, and centrifuge at 4 ° C for 10 minutes, ...

no. 3 example

[0119] Step 301, get the engineering bacteria, after amplifying with the bacteriolysis broth medium (LB medium), insert the engineering bacteria liquid according to 10% of the fermented body into the fermenter containing the high-density formula medium to enter the fermentation, the high-density Formula medium is 15g / L tryptone, 25g / L yeast extract, 17.5g / L hydrolase protein, 9g / L KH 2 PO 4 , 20g / L glucose;

[0120] Step 302, during the fermentation process, regularly and continuously drop increasing amounts of high-density formula culture medium;

[0121]Step 303, after 7 hours of fermentation, inducing the engineered bacteria at a temperature of 42°C for 4 hours, and releasing the fermented bacterial liquid from the fermenter after 11 hours of fermentation;

[0122] Step 304, take 100 g of engineering bacteria wet bacteria, add 800 ml of the first buffer solution (20 mmol / LTris-HCl (tris-hydrochloric acid), pH 8.0), wash the bacteria, and centrifuge at 4 ° C for 10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com