Metal laminated type of cylinder head gasket

A stacked type, cylinder head technology, applied in the direction of engine sealing, engine sealing device, machine/engine, etc., can solve the problem of no surface pressure to form a balance, and achieve the effect of stable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

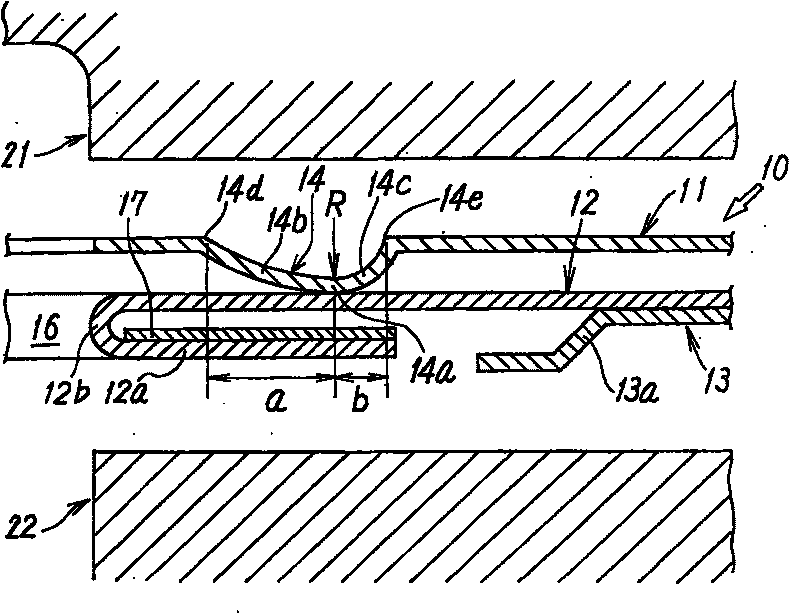

[0028] figure 1 It is a cross-sectional view showing the main part of an embodiment of the metal laminated cylinder head gasket according to the present invention, that is, the part around the combustion chamber hole 16 . The cylinder head gasket 10 is interposed between a cylinder head 21 and a cylinder block 22 of the engine. The cylinder head gasket is formed by laminating at least a plurality of metal plates, and in this embodiment, the cylinder head gasket 10 is composed of a first metal plate 11 on the outer layer, a second metal plate laminated on the first metal plate The plate 12 and the third metal plate 13 are formed.

[0029] The above-mentioned first metal plate 11 has an asymmetric protrusion 14 formed around the combustion chamber hole 16 . In this asymmetric protrusion 14, it is necessary to make the width a of the protrusion portion 14b having a larger curvature radius on the side of the combustion chamber hole 16 relative to the protrusion top 14a and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap