Directly mountable strap-like reinforced fuel tank arrangement for motor vehicles

A technology for motor vehicles and fuel tanks, which is applied in the direction of the power plant, the arrangement combined with the fuel supply of the internal combustion engine, and vehicle components, to achieve the effects of reducing costs, achieving mechanical strength, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

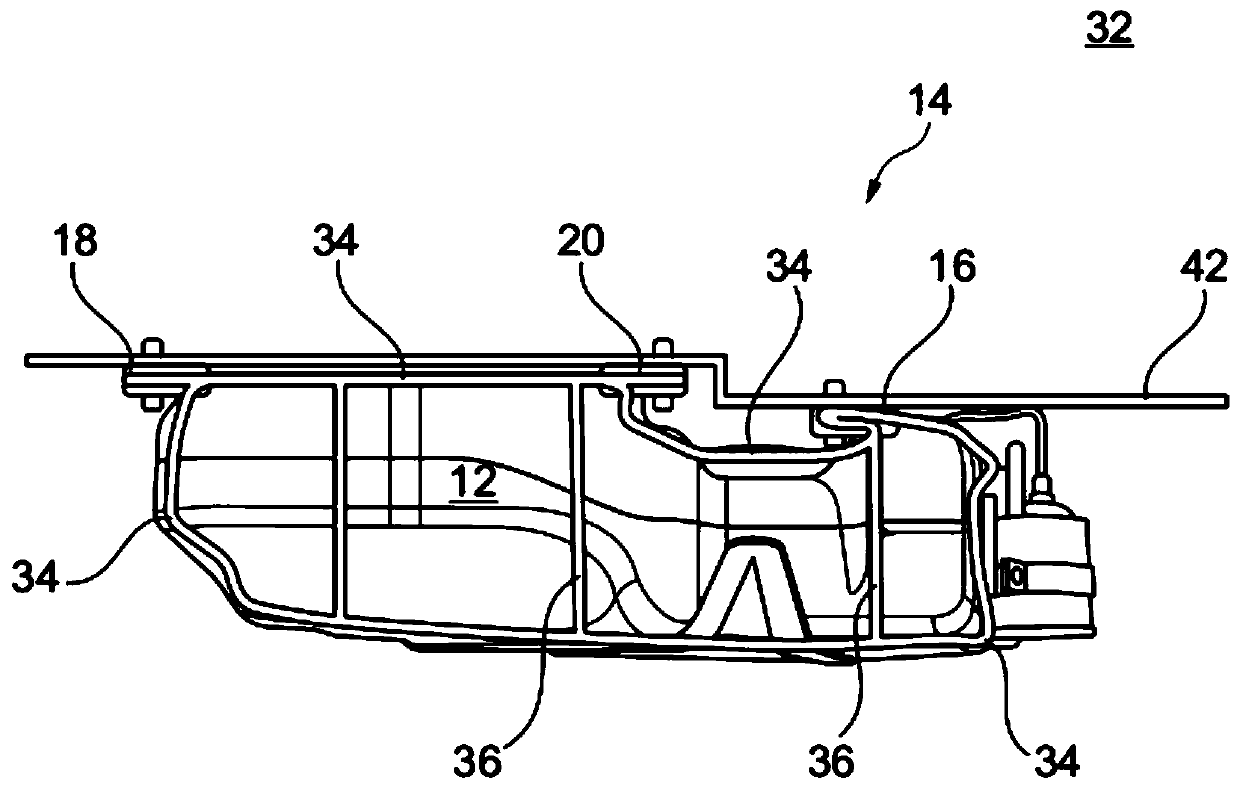

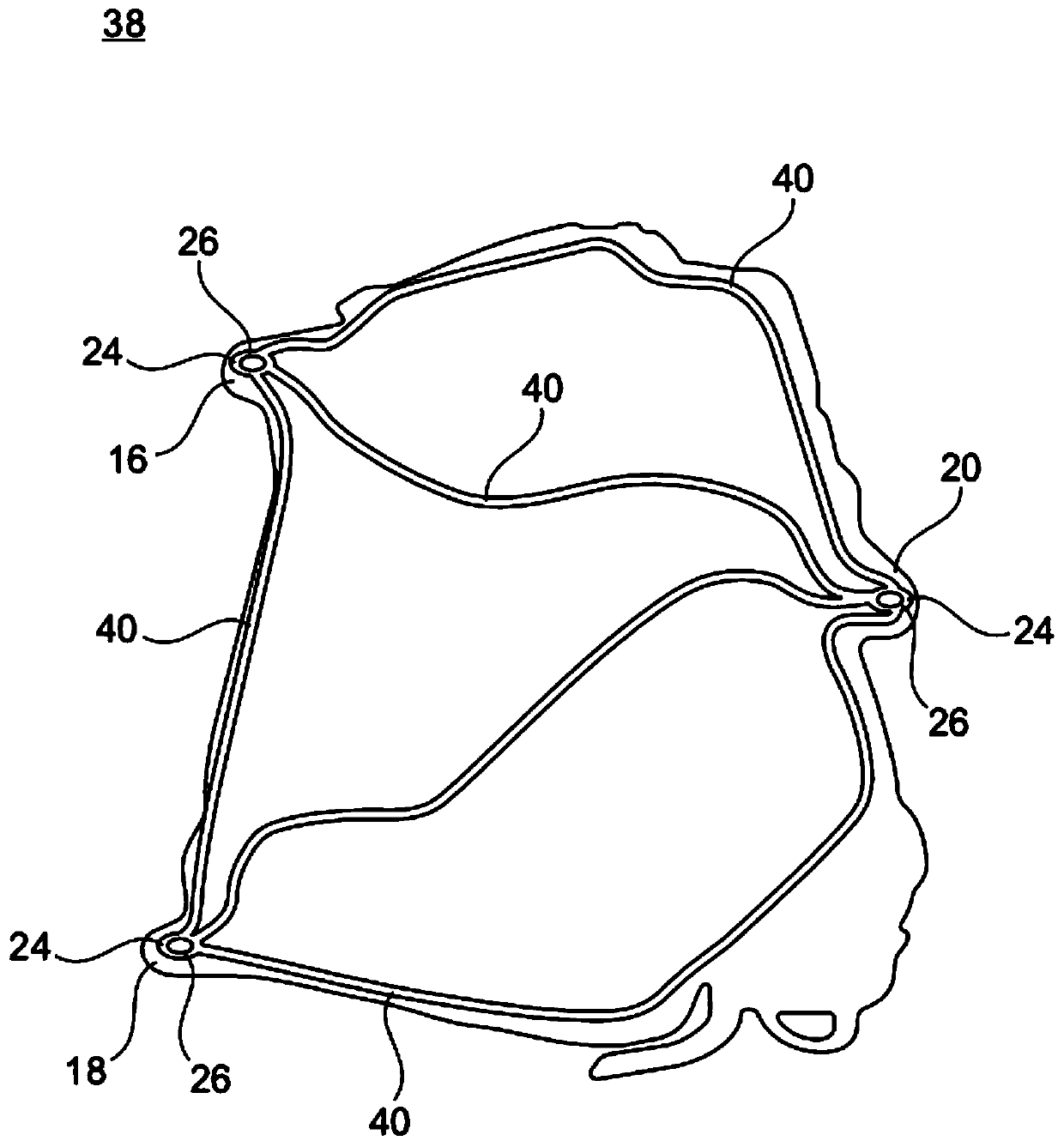

[0057] In the different figures, identical parts are always given the same reference numerals, so they are usually also described only once.

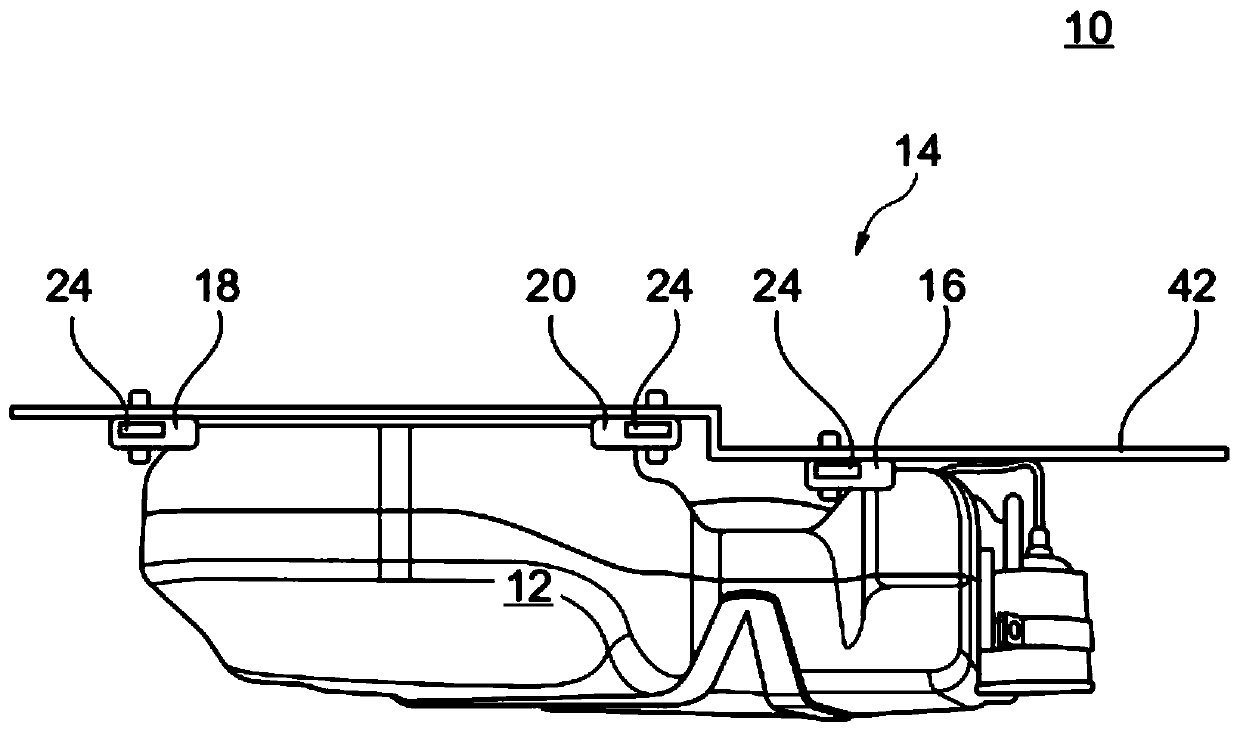

[0058] figure 1 is a side view of a possible embodiment of a fuel tank arrangement 10 for a motor vehicle according to the invention. The fuel tank arrangement 10 is shown in a state in which the fuel tank arrangement 10 is mounted on a chassis 42 of a motor vehicle, which is constructed as a passenger car.

[0059] The fuel tank arrangement 10 has a fuel tank 12 for containing fuel and a fixing device 14 for fixing the fuel tank 12 to a motor vehicle.

[0060] Fuel tank 12 comprises a first thermoplastic material, which in this particular embodiment is formed from high density polyethylene (PE-HD). In other embodiments, the first thermoplastic material may be made of medium density polyethylene (PE), polypropylene (PP), polyamide (PA), polyphenylene sulfide (PPS), foamed forms of the mentioned materials or at least A combination of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap