Magnetic force interlocking valve without sealing by filling materials and sealing ring

A sealing ring and magnetic technology, which is applied to the valve field of ferromagnetic material rotor to realize on-off control, can solve the problems of water leakage and failure, internal structure failure, and inability to maintain two-way power after power failure, so as to solve the problem of maintaining the valve position after power failure. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

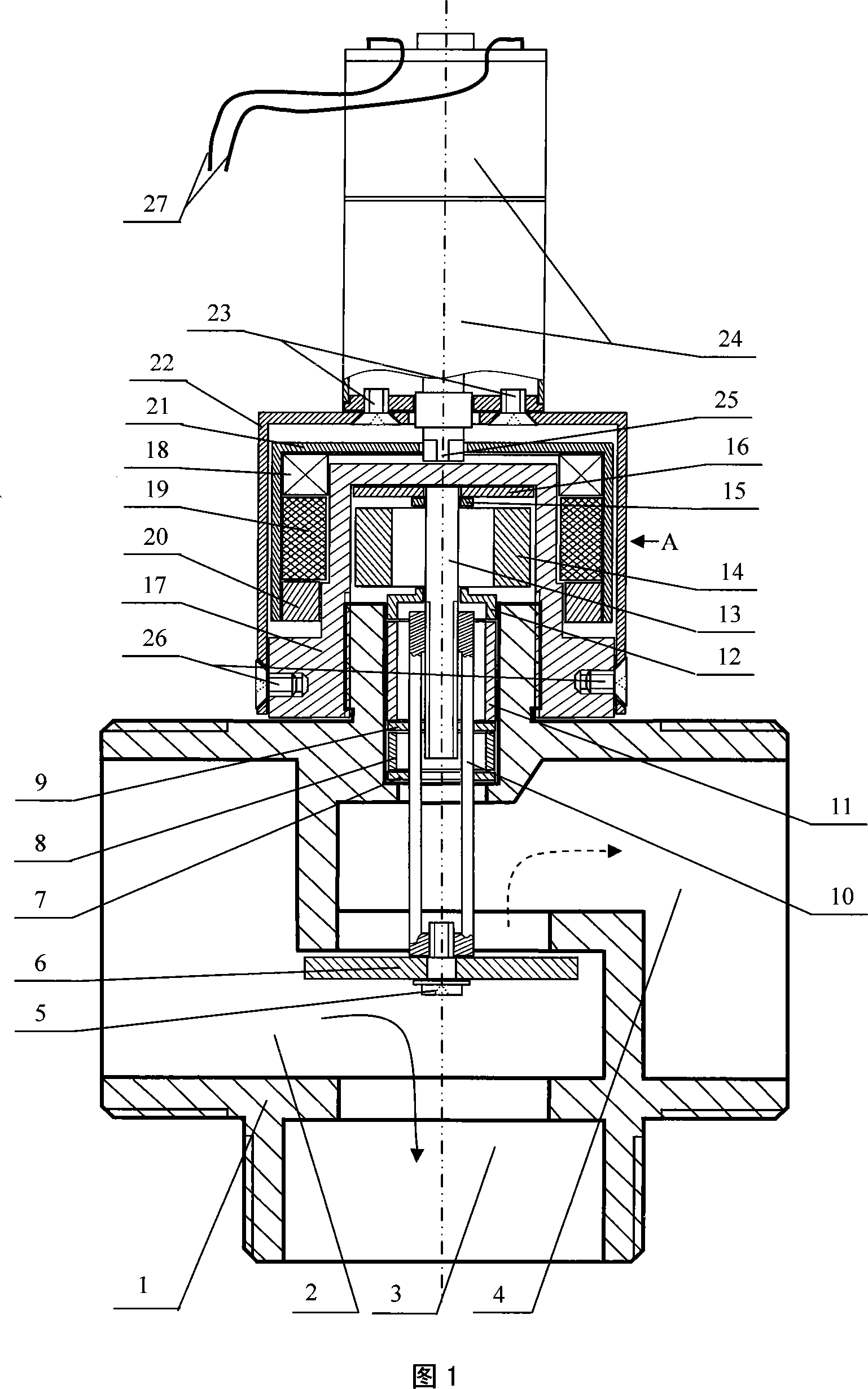

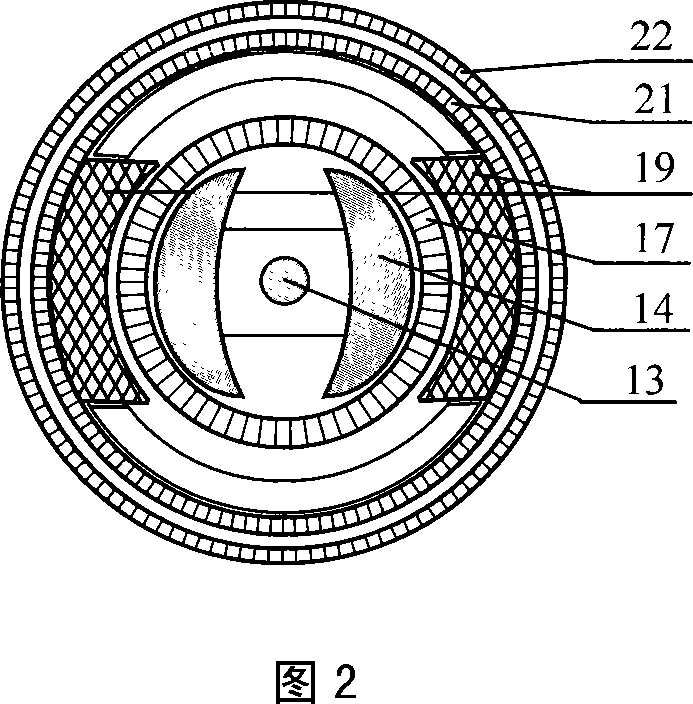

[0025] See attached drawing 1.

[0026] The permanent magnet positioning rings 18, 20, the permanent magnet 19, and the outer rotor shell 21 are assembled into an outer rotor. The inner rotor 14 and the threaded inner rotor shaft 13 are fixedly fastened together. The reduction motor 24 and the outer rotor shield 22 are fixed together with the motor fixing screws 23 . The valve plate 6 is sent into the valve cavity through the water inlet of the valve body 1, and the valve plate 6 and the valve stem 10 are fixed as a whole with the screw 5 . Then put the valve stem brackets 7, 8, 9, the valve stem bracket positioning jacking pipe 11, and the inner rotor shaft positioning frame 12 into the cavity shown in the figure in sequence. The inner rotor 14 and the threaded inner rotor shaft 13 fixed together in advance are inserted into the hole of the inner rotor shaft positioning frame 12, and a part of the thread is screwed into the screw hole of the valve stem 10. Insert the gaske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com