Stable-state high-power water load

A high-power, water-loaded technology, applied in the direction of electric power measurement by thermal method, can solve the problems of low thermal conductivity of rubber materials, difficult heat conduction, water leakage in the water tank, etc., to reduce the force and eliminate the hidden danger of water leakage , the effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

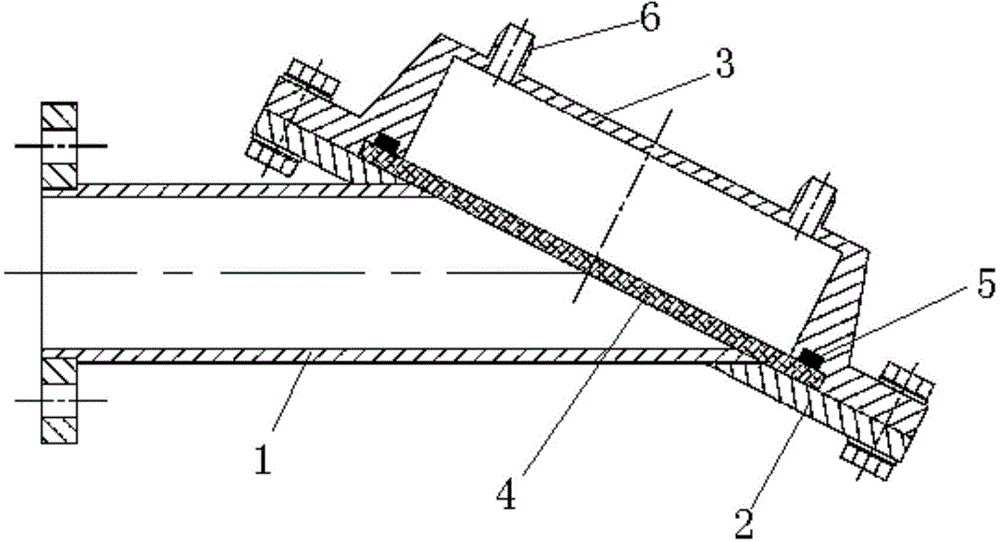

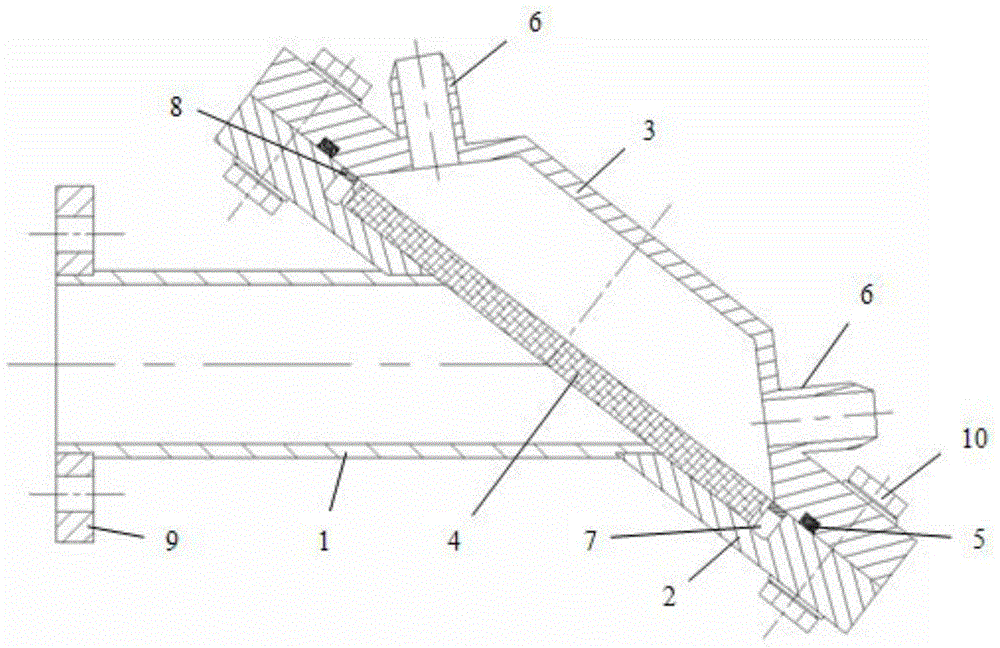

[0015] Such as figure 1 shown. Steady-state high-power water load, including a rectangular waveguide 1 with a straight cavity inside and two ends respectively set as cavity openings, a waveguide flange 9 is installed on the cavity wall at one end of the rectangular waveguide 1, and a cavity wall at the other end of the rectangular waveguide 1 It is processed into a slope shape to form a bevel, and a circular flange 2 flush with the bevel is installed on the wall of the bevel. The circular flange 2 is provided with a ceramic sheet 4 covering the bevel. It is also provided with an annular groove 7 surrounding the outside of the ceramic sheet 4. The notch of the annular groove 7 is provided with a metal ring 8, and also includes a metal cavity 3. The water interface 6, and the metal cavity 3 is installed on the waveguide circular flange 2.

[0016] A sealing groove surrounding the annular groove 7 is provided on the joint surface of the metal cavity 3 and the circular flange 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com