Cooling structure of construction machine

A technology of construction machinery and structure, which is applied in the combination of cooling arrangement of buildings and power units, earth movers/excavators, etc., to achieve the effect of improving cooling capacity and reducing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

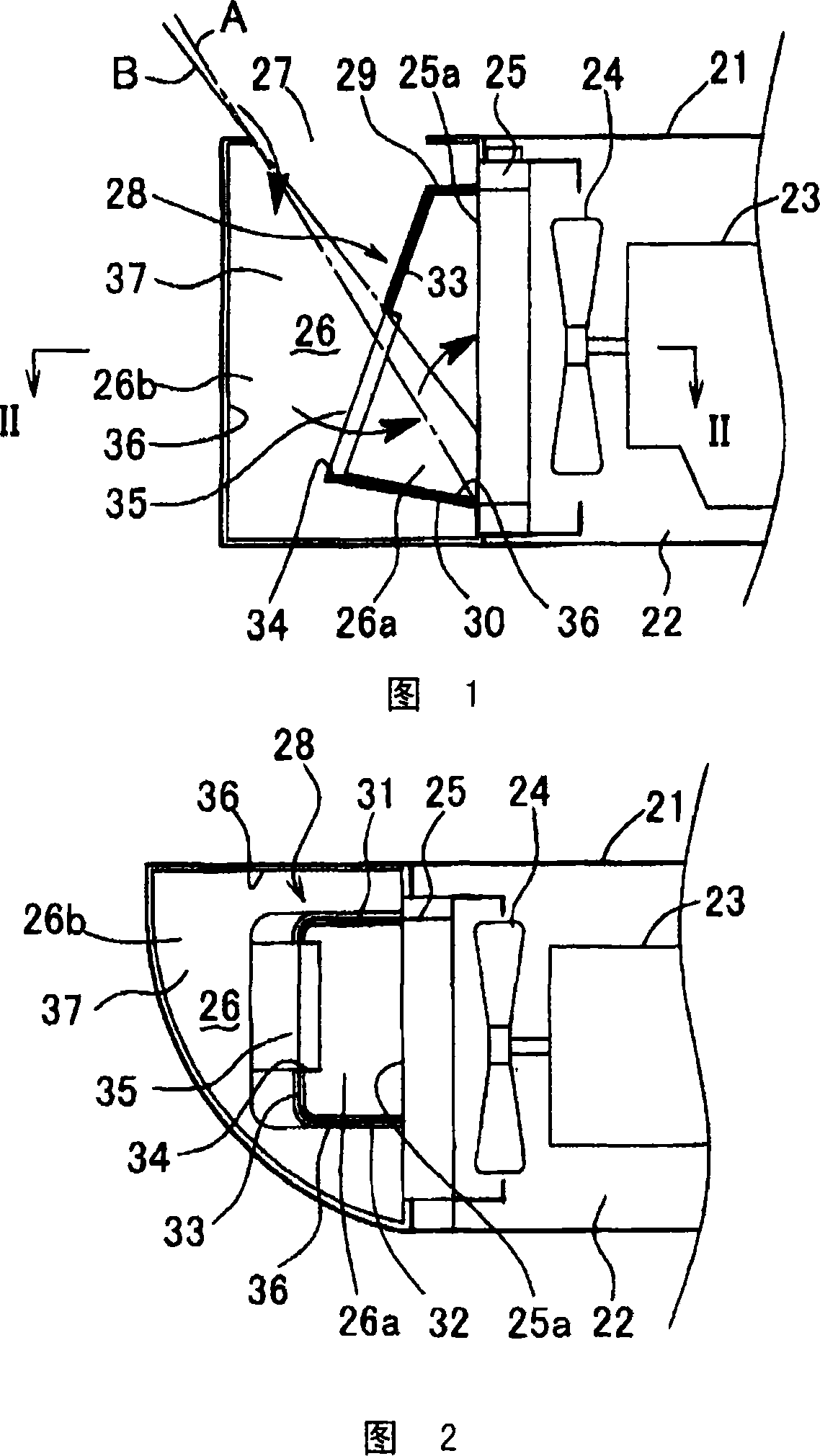

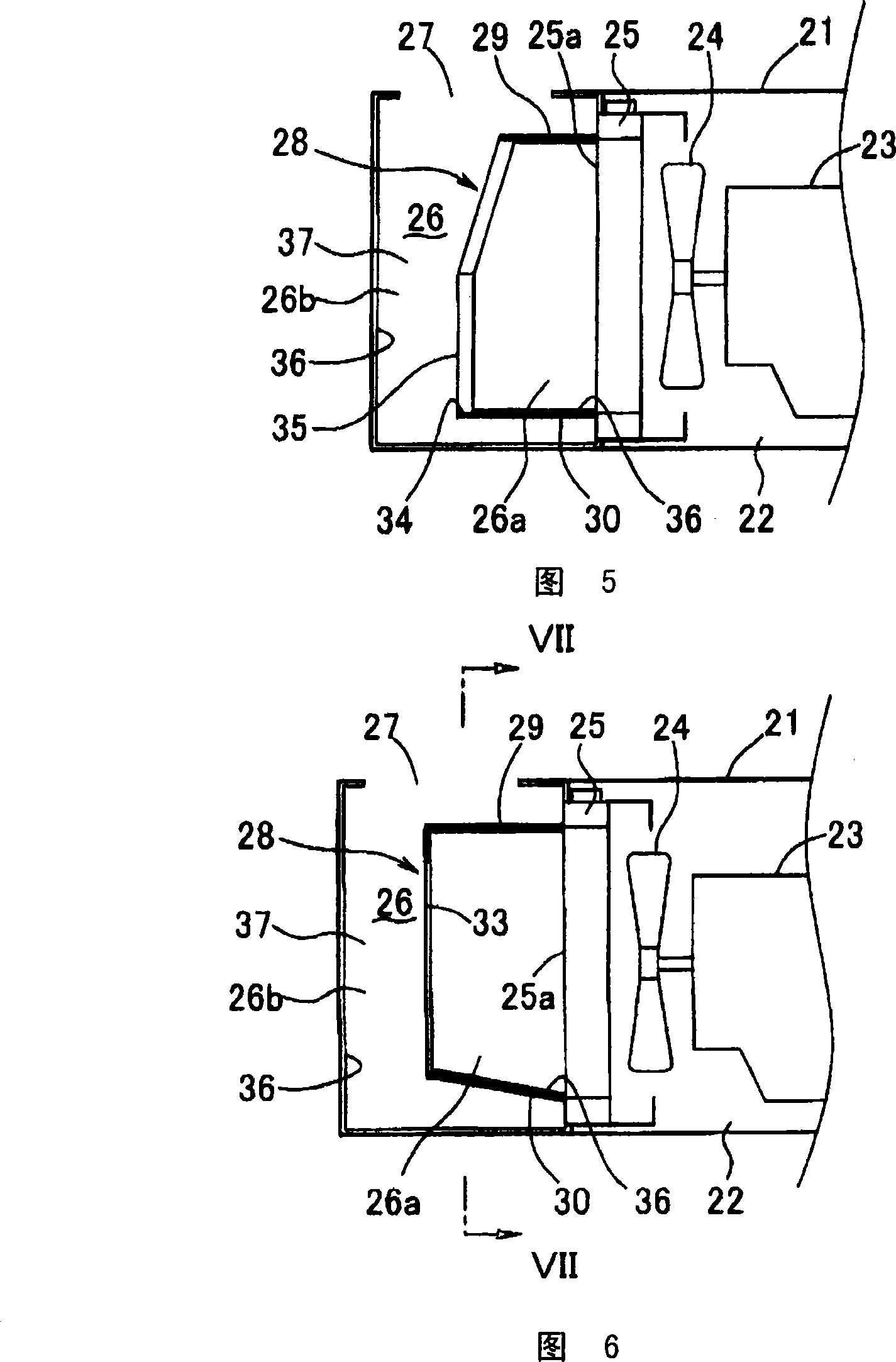

[0048] First Embodiment (Refer to FIG. 1 and FIG. 2 )

[0049] In each of the first to ninth embodiments shown in FIGS. 1 to 11 , ducts are provided as shielding members.

[0050] In the first embodiment, the following basic structure is the same as the technique shown in FIG. 13 .

[0051] (A) An engine compartment 22 covered with a cover material 21 such as an engine guard, a part of a counterweight, and an upper surface of a fuel tank is provided at the rear of the upper revolving body.

[0052] (B) Heat exchangers (one of which is shown here) 25 such as an engine 23 , a hydraulic pump not shown, a cooling fan 24 , and a radiator are provided in the engine room 22 .

[0053] (C) An air intake chamber 26 is formed on the air intake side of the heat exchanger 25 in the engine compartment 22, and a first air intake chamber for introducing air from the outside is provided on the upper surface of the air intake chamber 26 (the upper surface portion of the cover material 21). Air...

no. 2 approach

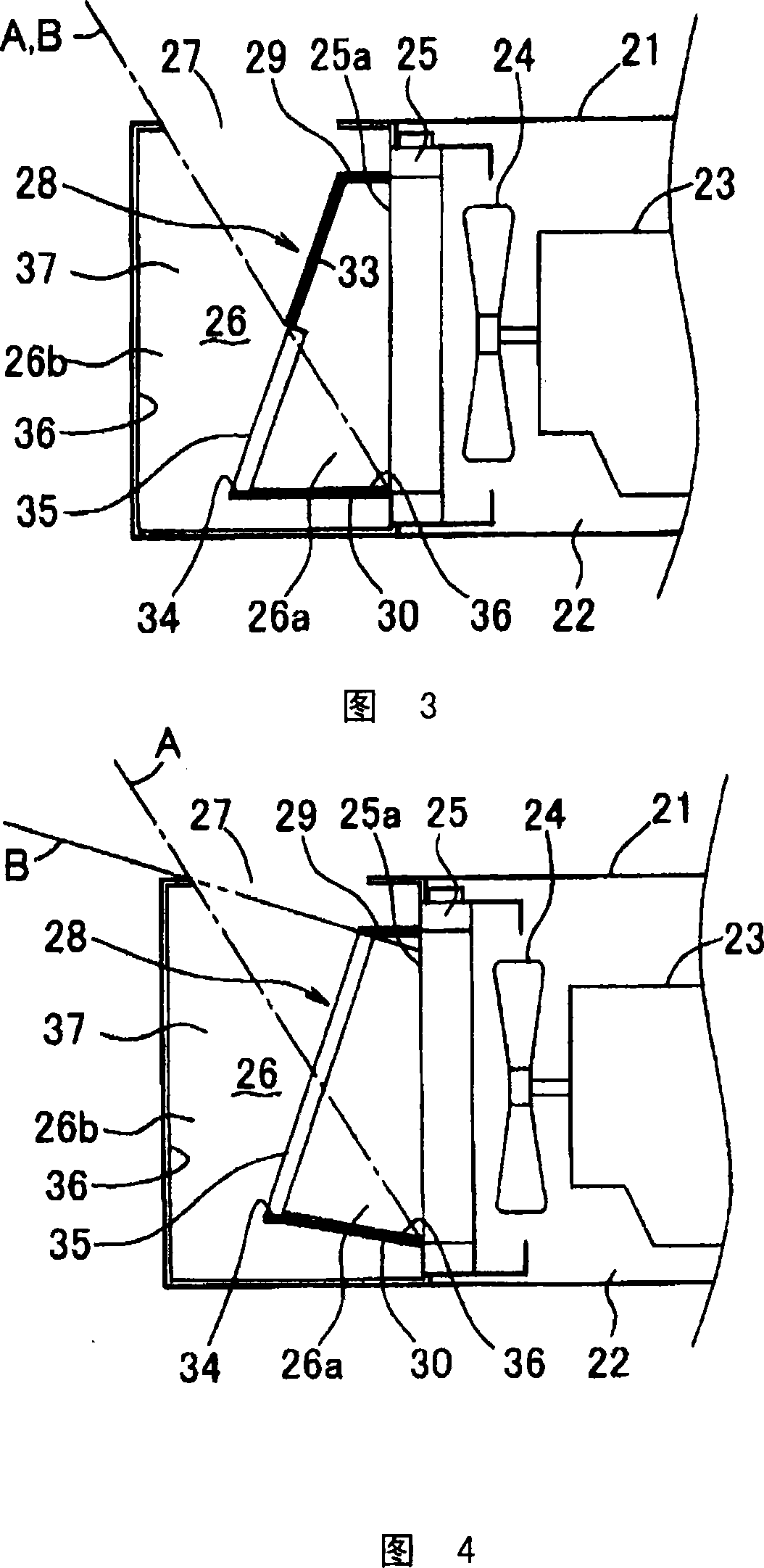

[0081] Second embodiment (refer to FIG. 3 )

[0082] In the first embodiment, it is arranged so that a part of the heat exchanger core surface 25 a cannot be directly seen from the outside through the first and second intake ports 27 , 34 .

[0083] Specifically, as shown in FIG. 1, it is arranged so that: the straight line B connecting the outermost end of the first air inlet 27 and the upper end of the second air inlet 34 is less than the straight line B connecting the outer end of the first air inlet and the heat exchanger core. The straight line A at the lower end of the surface 25a is slightly but notably on the upper side.

[0084] Thus, leakage of direct sound, which is directly discharged from the heat exchanger core surface 25a to the outside, occurs, though rarely.

[0085] In the second embodiment, as an improvement technique for this point, the second air inlet 34 is made smaller than that of the first embodiment while maintaining the same size of the second air i...

no. 3 approach

[0088] Third embodiment (refer to FIG. 4 )

[0089] In the first and second embodiments, the second suction port 34 is provided only on the suction downstream side (lower half) of the duct front portion 33 , but in the third embodiment, the duct front portion The entire surface of the is provided with a second suction port 34 . In addition, at this time, since the duct front part does not exist substantially as a surface, it is not attached with the code|symbol in FIG. 4. FIG.

[0090] According to this structure, the range directly seen from the outside of the heat exchanger core surface 25a becomes larger, so it is disadvantageous in terms of direct sound isolation, but since the sucked air can be supplied to the heat exchanger core surface 25a with the minimum resistance , so it is advantageous in terms of cooling efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com