Large-span moving staircase girders and Large-span moving staircase formed thereby

An escalator and large-span technology, applied in escalators, transportation and packaging, etc., can solve the problems of unguaranteed lateral stiffness and stability of trusses and multiple building spaces, saving building space, enhancing safety, and ensuring lateral Effects of stiffness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

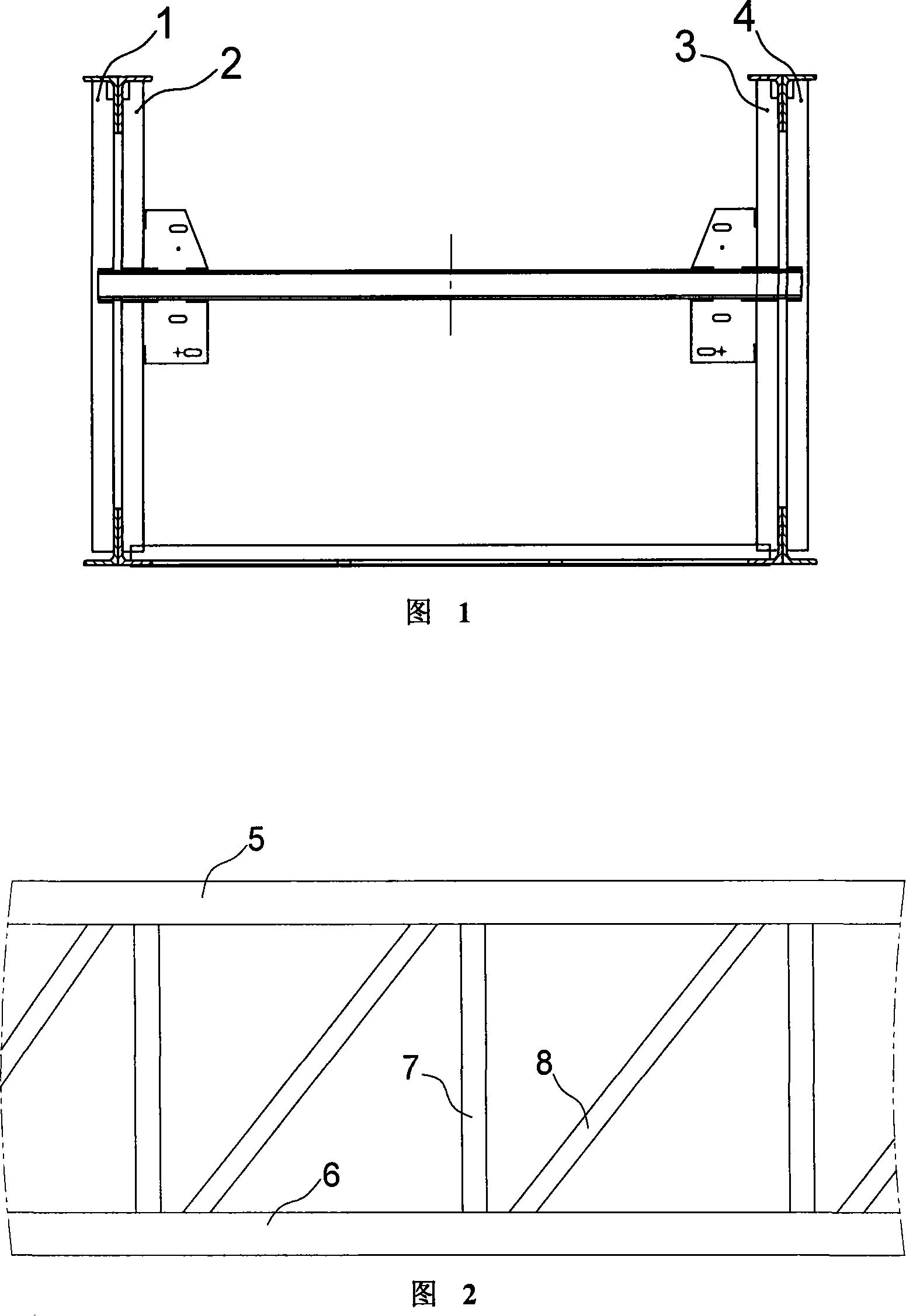

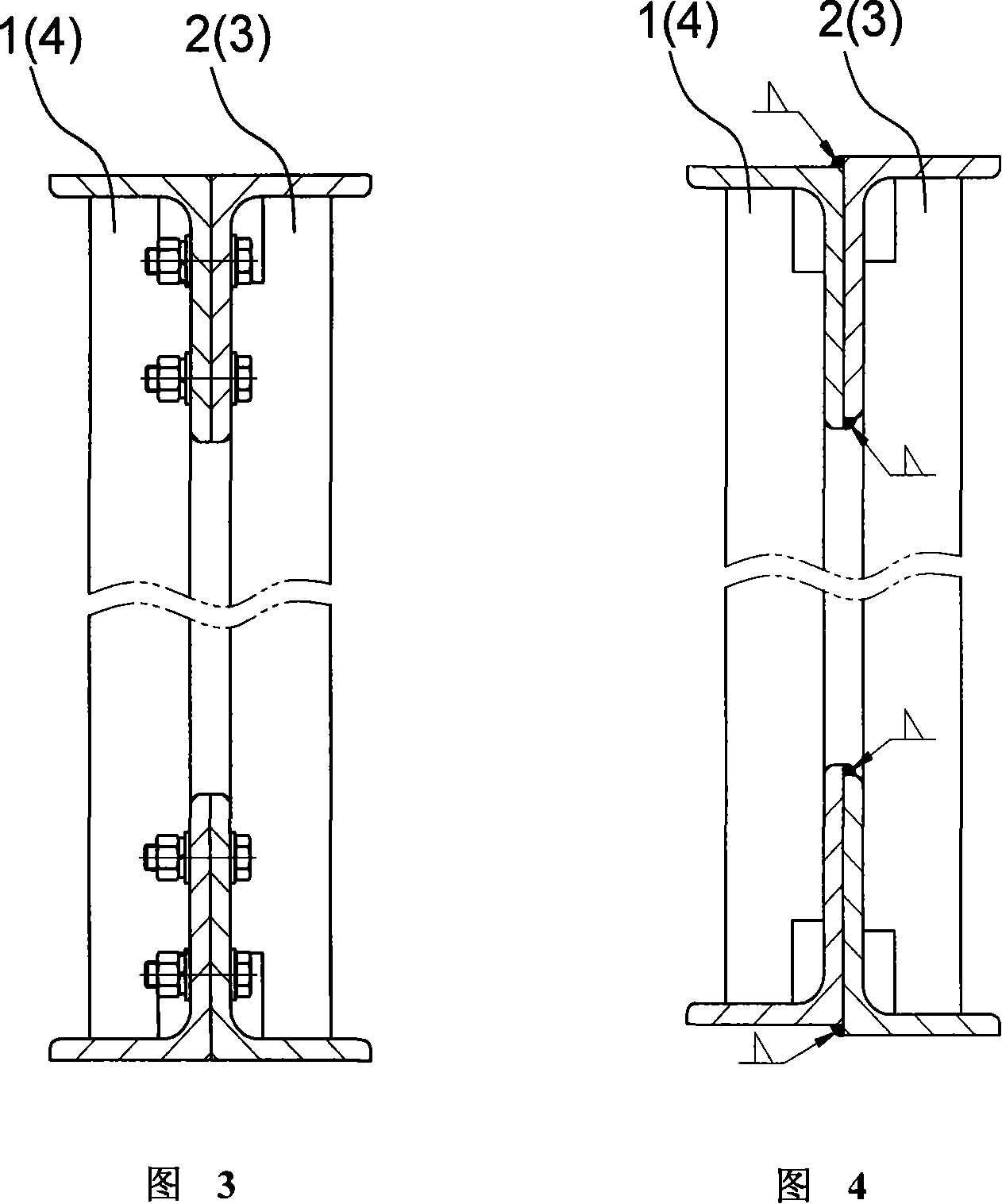

[0020] Embodiment 1: As shown in Figure 1 and Figure 2, a large-span escalator truss includes a truss single piece, which consists of four truss single pieces, namely, the left outer single piece 1, the left inner single piece 2, and the right inner single piece 3 and right outer monolithic 4 constitute. The left outer single piece 1 and the left inner single piece 2 are closely connected together by bolts, and the right inner single piece 3 and the right outer single piece 4 are closely connected together by bolts.

[0021] In the present invention, two truss monoliths are added on the outside, and the size in the width direction only needs to be slightly increased, so that the strength can be greatly improved, and at the same time, the thickness of the inclined part of the monolith can be increased to meet the needs of large-span escalators without intermediate support , to ensure the lateral rigidity and stability of the truss, enhance the safety of the escalator, and save ...

Embodiment 2

[0024] Embodiment 2: This embodiment is a long-span escalator truss. The difference between it and Embodiment 1 is that, as shown in Figure 4, the left outer single piece 1 and the left inner single piece 2 are closely connected together by welding , the right inner single piece 3 and the right outer single piece 3 are tightly connected together by welding.

Embodiment 3

[0025] Embodiment 3: This embodiment is a large-span escalator, which has the truss described in Embodiment 1, including a truss monolith, consisting of four truss monoliths, namely the left outer monolith 1, the left inner monolith 2, Right inner single piece 3 and right outer single piece 4 constitute. The left outer single piece 1 and the left inner single piece 2 are closely connected together by bolts, and the right inner single piece 3 and the right outer single piece 4 are closely connected together by bolts.

[0026] The upper chord 5 and the lower chord 6 of the truss single piece, that is, the left outer single piece 1, the left inner single piece 2, the right inner single piece 3 and the right outer single piece 4 adopt square tubes or angle steel, and the vertical rod 7 and the oblique Bar 8 adopts square tube or angle steel or channel steel. The truss pieces on the left and right sides are welded and connected by the beam and the back cover plate in the tradition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com