Emergency braking arrangement for automobiles

An emergency braking, automobile technology, applied in the direction of brakes, braking components, vehicle parts, etc., can solve the problems of road damage, high hydraulic pressure, affecting braking effect, etc., to increase adhesion, prevent car accidents, save money The effect of braking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

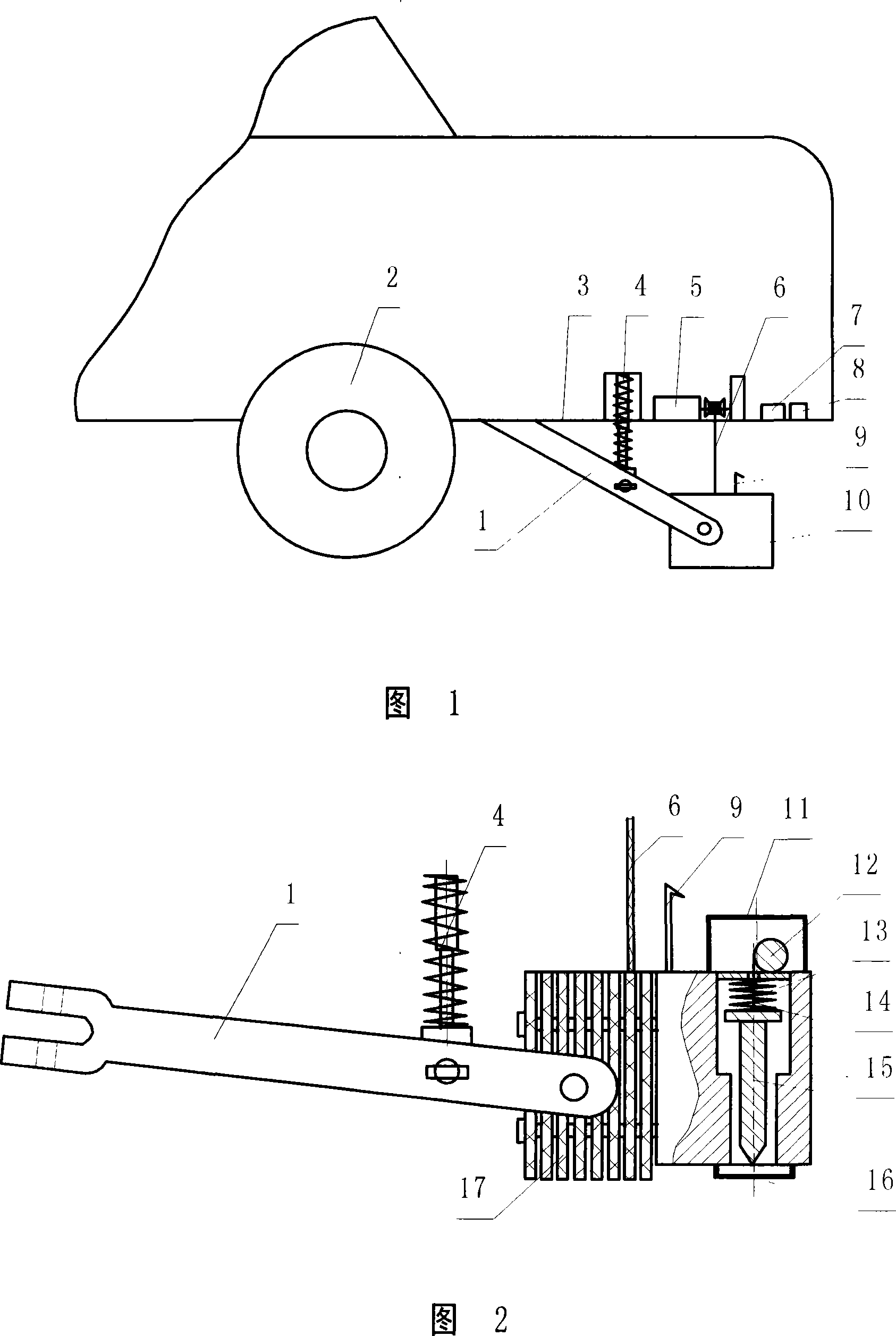

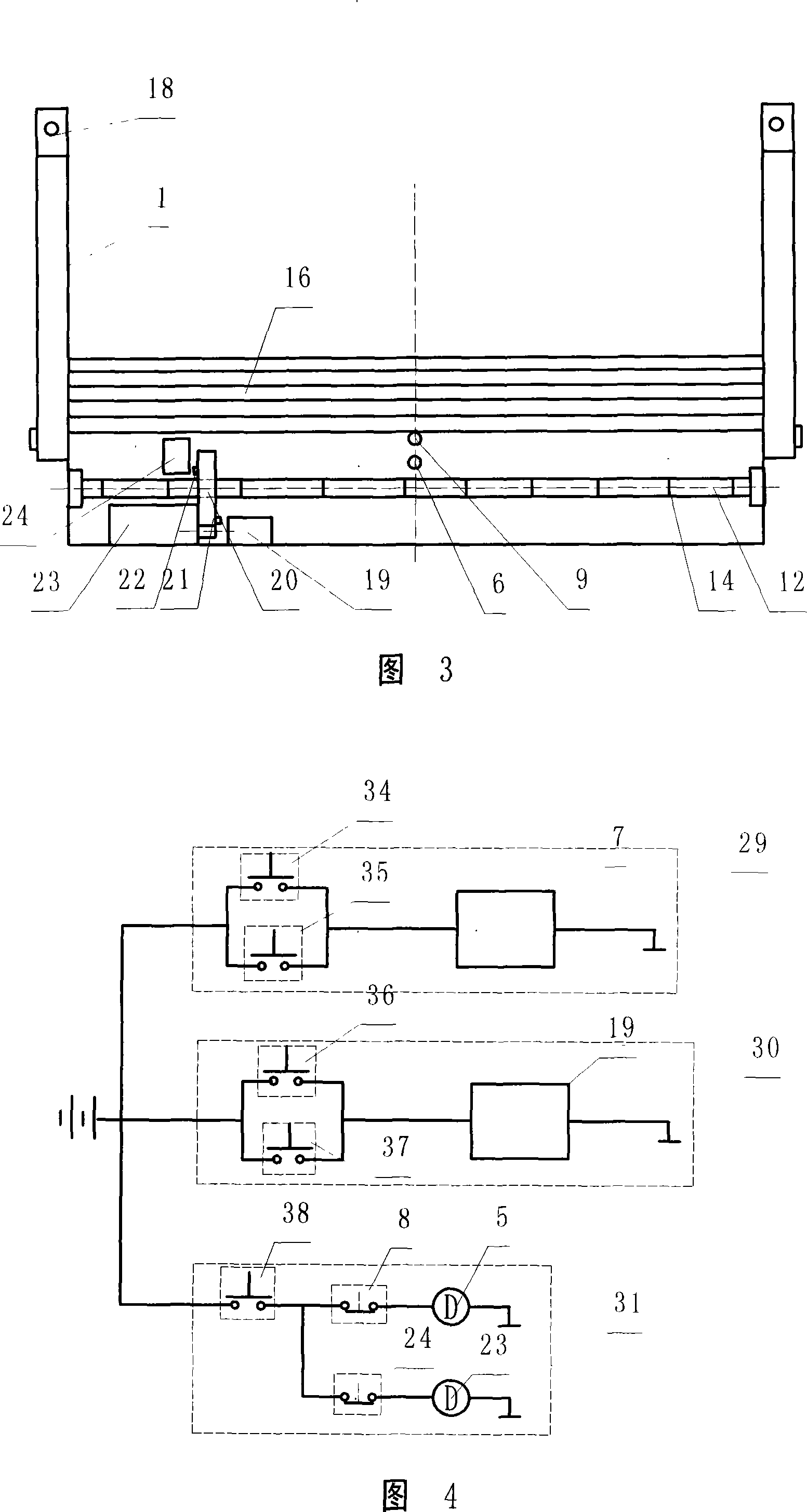

[0021] With reference to accompanying drawing 1, Fig. 2, Fig. 3, Fig. 4, present embodiment comprises the fixing frame that is fixedly installed in the rear bottom of automobile, dragging anchor type brake, dragging anchor type brake lifting device, it is characterized in that described dragging anchor type brake is set There is a dragging anchor arm 1, and a dragging anchor brake main body 10 is connected with the dragging anchor arm 1. A plurality of friction-resistant and high-temperature-resistant brake composite material plates 17 are installed on the dragging anchor brake main body 10, and are fixed with fastening nails 18. Close to the brake composite material plate 17, ten retractable brake nails 15 are arranged side by side, and the brake nails 15 are connected with a brake nail lifting device. 1 is provided with a booster spring 4, and the upper end of the booster spring 4 is fixedly connected to the bottom plate 3 of the rear box. Be provided with motor I5, solenoid...

Embodiment 2

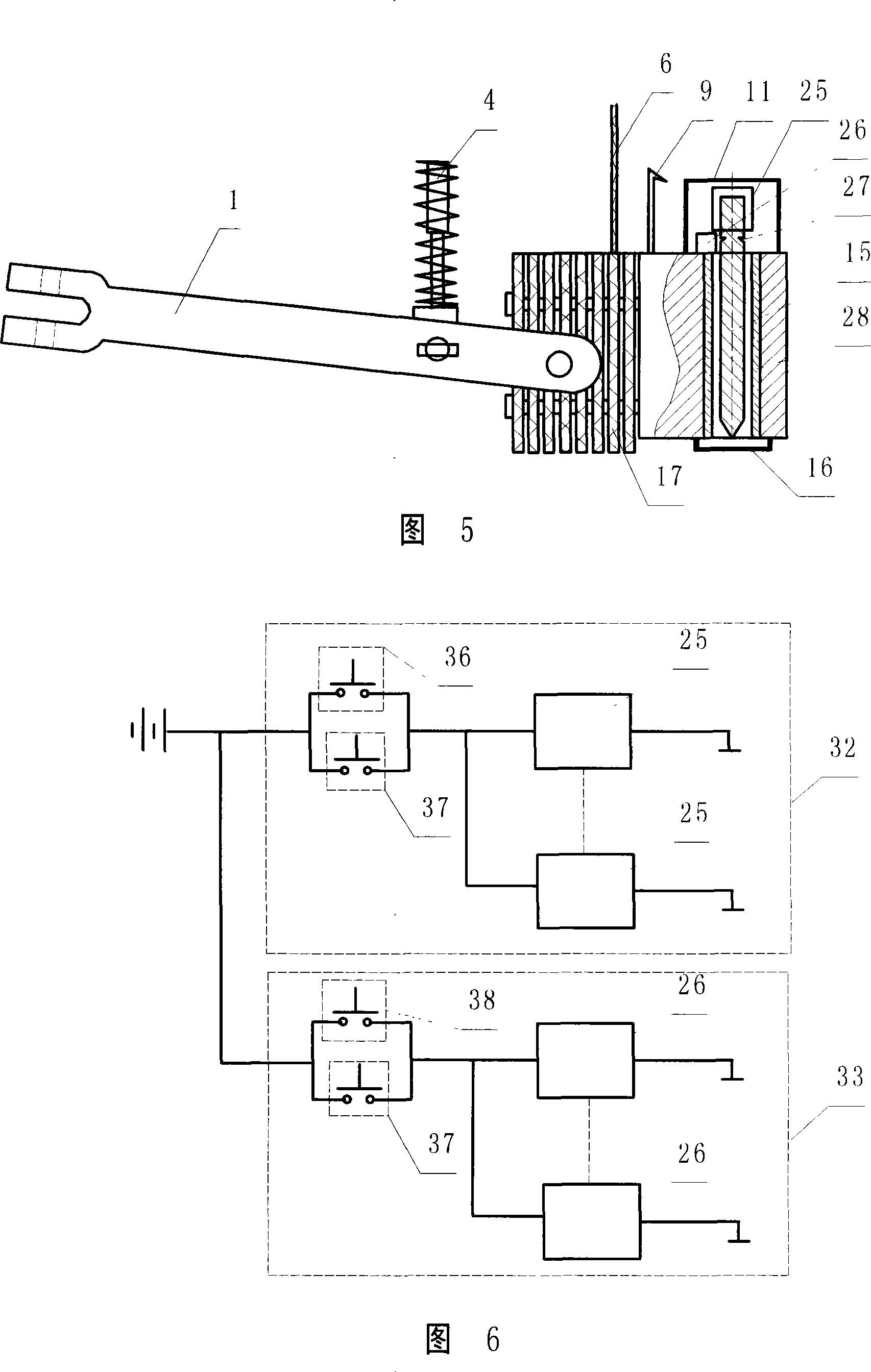

[0030] With reference to Fig. 5, shown in Fig. 6, compared with embodiment 1, the difference of this embodiment is that the brake nail elevating device, its structure is in the upper part of drag anchor type brake main body 10, each brake nail 15 is equipped with Electromagnetic valve III25 and electromagnetic valve IV26, brake nail positioning groove 27 is provided on the top of brake nail 15, and magnetic isolation sleeve 28 is provided in the brake nail whereabouts hole.

[0031] It works as follows:

[0032] When ice and snow appear on the road surface, utilize manual switch III38 or road surface detection switch 37, energize to make solenoid valve IV26 action, solenoid valve IV26 pin is extracted from brake nail positioning groove 27, and brake nail 15 falls.

[0033] When there is no need for the brake pin to brake, the manual switch II36 or the road surface detection switch 37 can be used to energize the solenoid valve III25, and the brake pin 15 will be lifted up rapid...

Embodiment 3

[0036] Compared with Embodiment 1, the difference of this embodiment is that the upper part of the main body 10 of the drag anchor brake is provided with an upper dust cover 11 to prevent dust accumulation and ensure the normal operation of components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com