Device for loading machines handling bulk materials

A loading device, technology for bulk materials, applied in the field of devices for loading machines handling bulk materials, able to solve problems such as efficiency limitations, and achieve the effect of efficient driving, simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

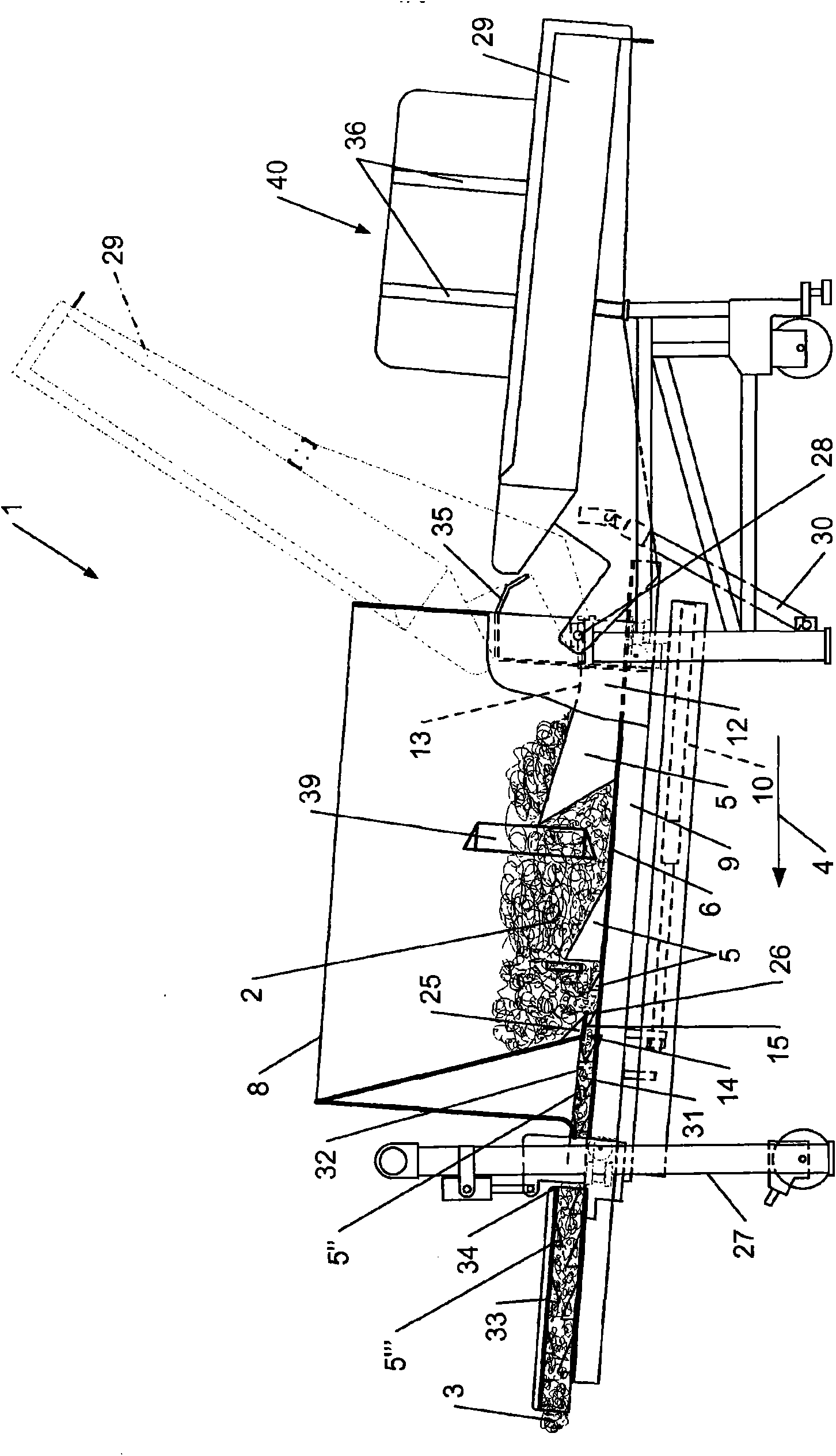

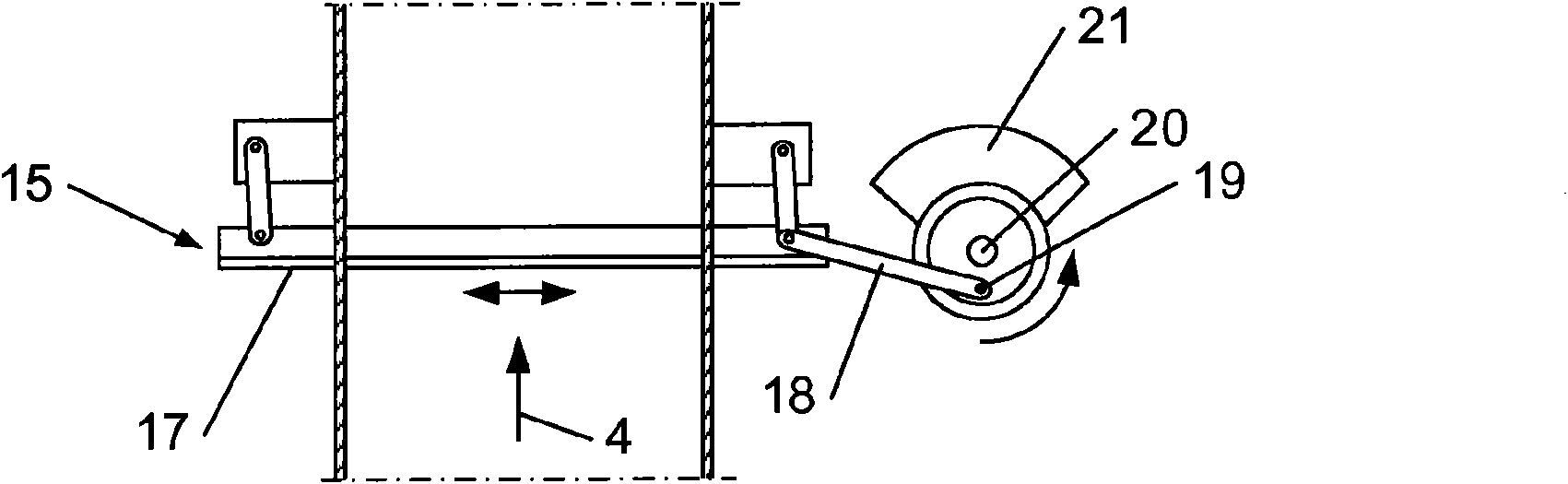

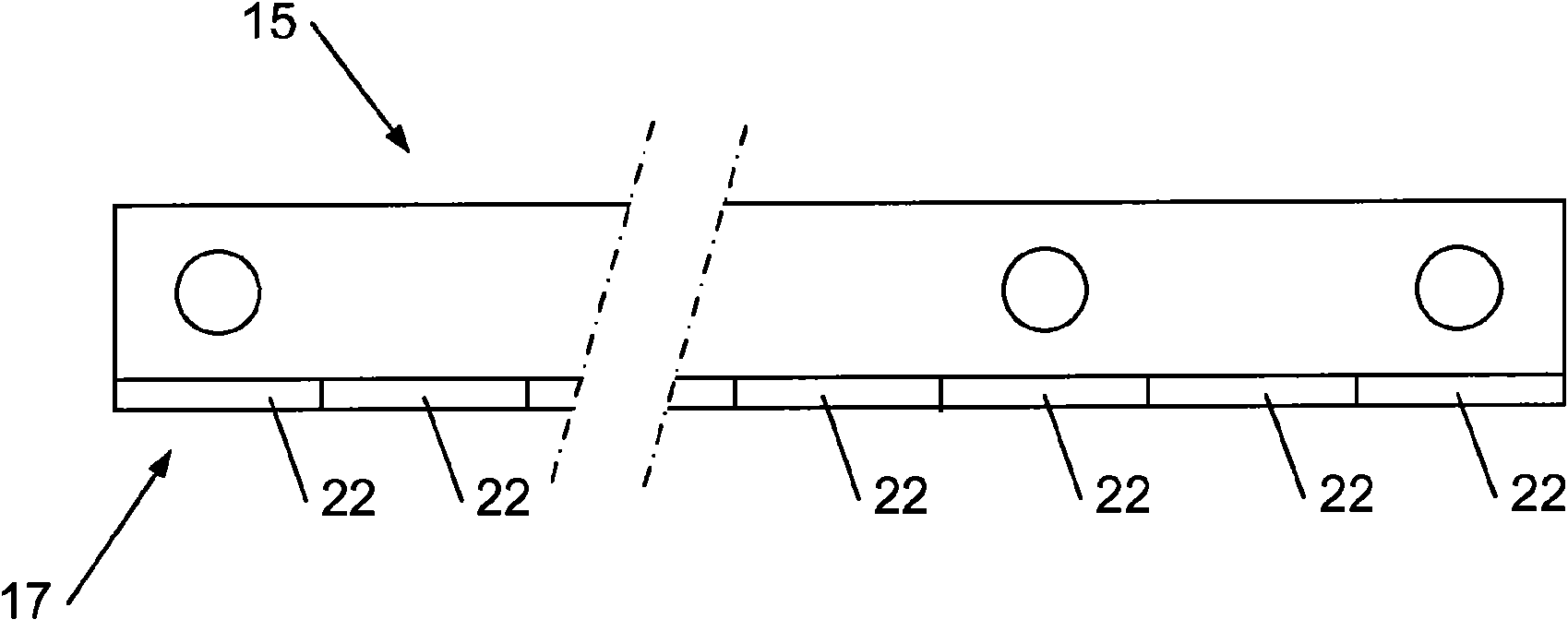

[0037] According to the invention and as shown in the accompanying drawings in particular figure 1 with 5 The shown loading device 1 is used to load a machine (such as a fiber cutter) with fibers, which can continuously extract fibers from a stock pile 2 to form a belt 3 having the same characteristics as the material capable of being absorbed by the cutter. Corresponding to the cross section of the cross section, the loading device can also move the belt 3 uniformly towards the cutter until the belt is picked up by the conveyor belt of the cutter. The extraction of the material takes place by means of a first set of protruding elements 5 penetrating the heap, at least some of which are movable, and by their movement organize the fibers to form the belt 3 and make the belt 3 in the driving direction 4 up and forward.

[0038] In the device of this exemplary embodiment, these protruding elements 5 are hooks fixed (preferably detachable) to two movable plates 6 and a fixed pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com