Separation apparatus for pdp panel assembly and method for controlling the same

A technology for plasma display screens and separation equipment, applied in the direction of layered products, electrical components, electronic waste recycling, etc., capable of solving problems such as deformation and surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

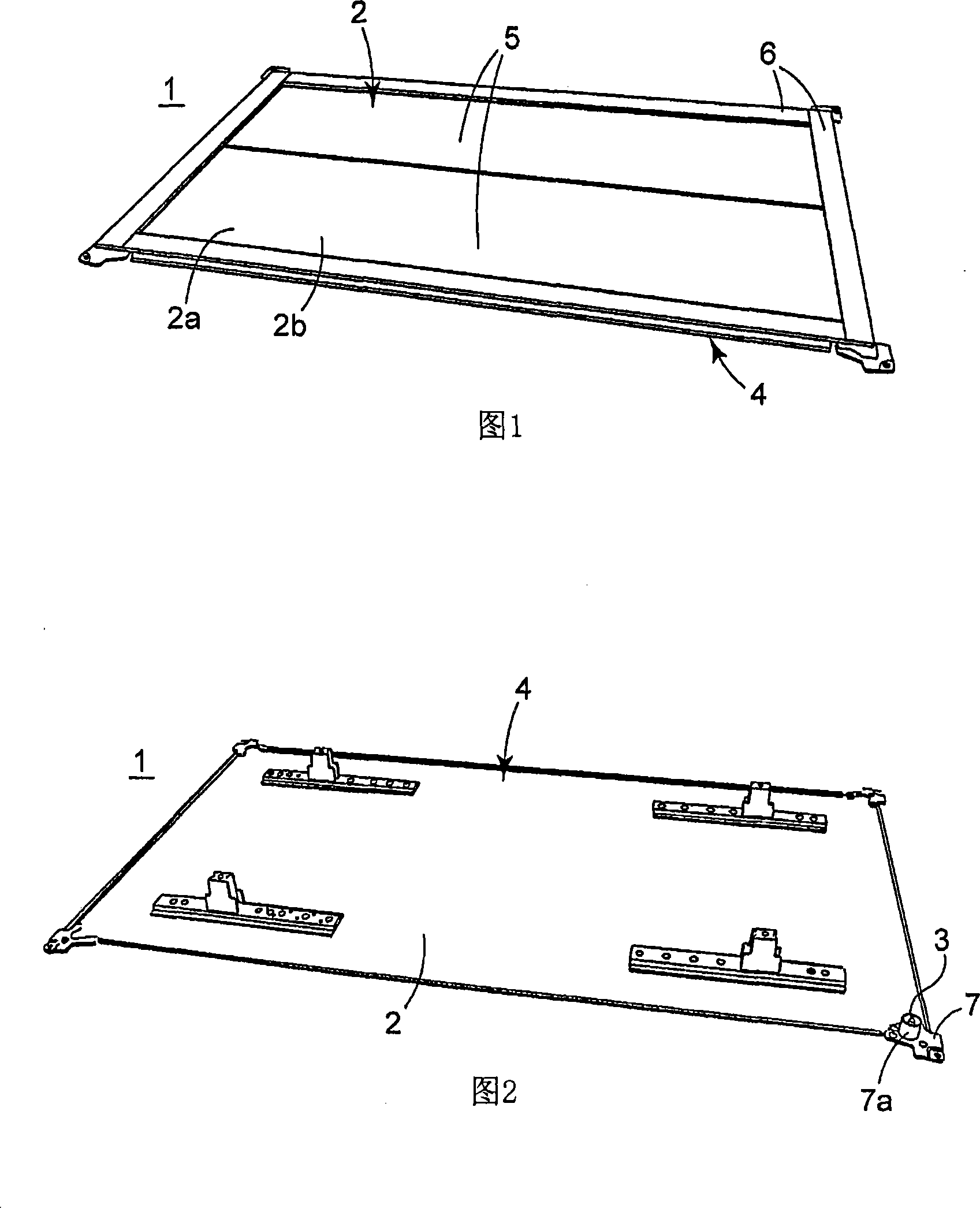

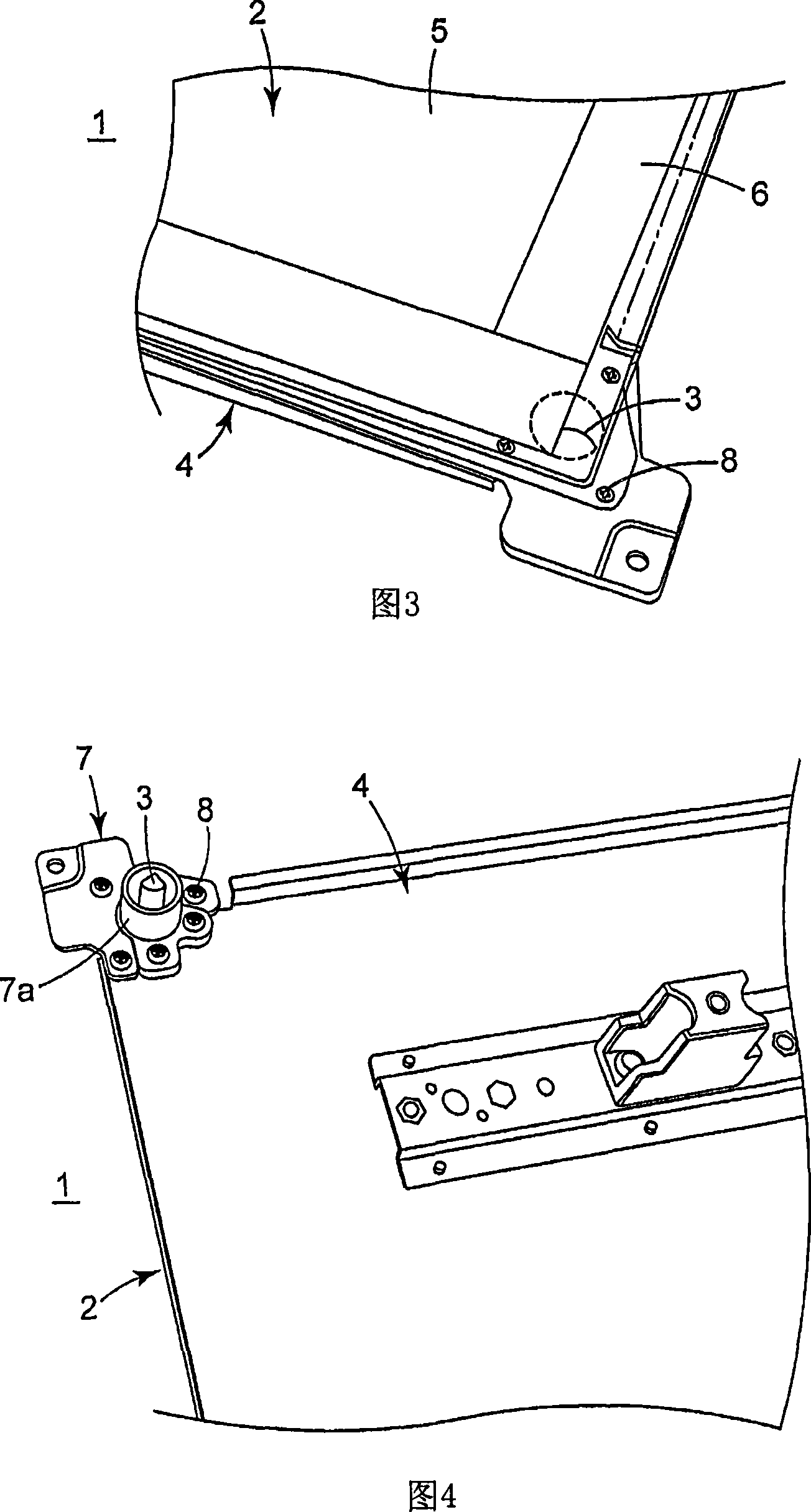

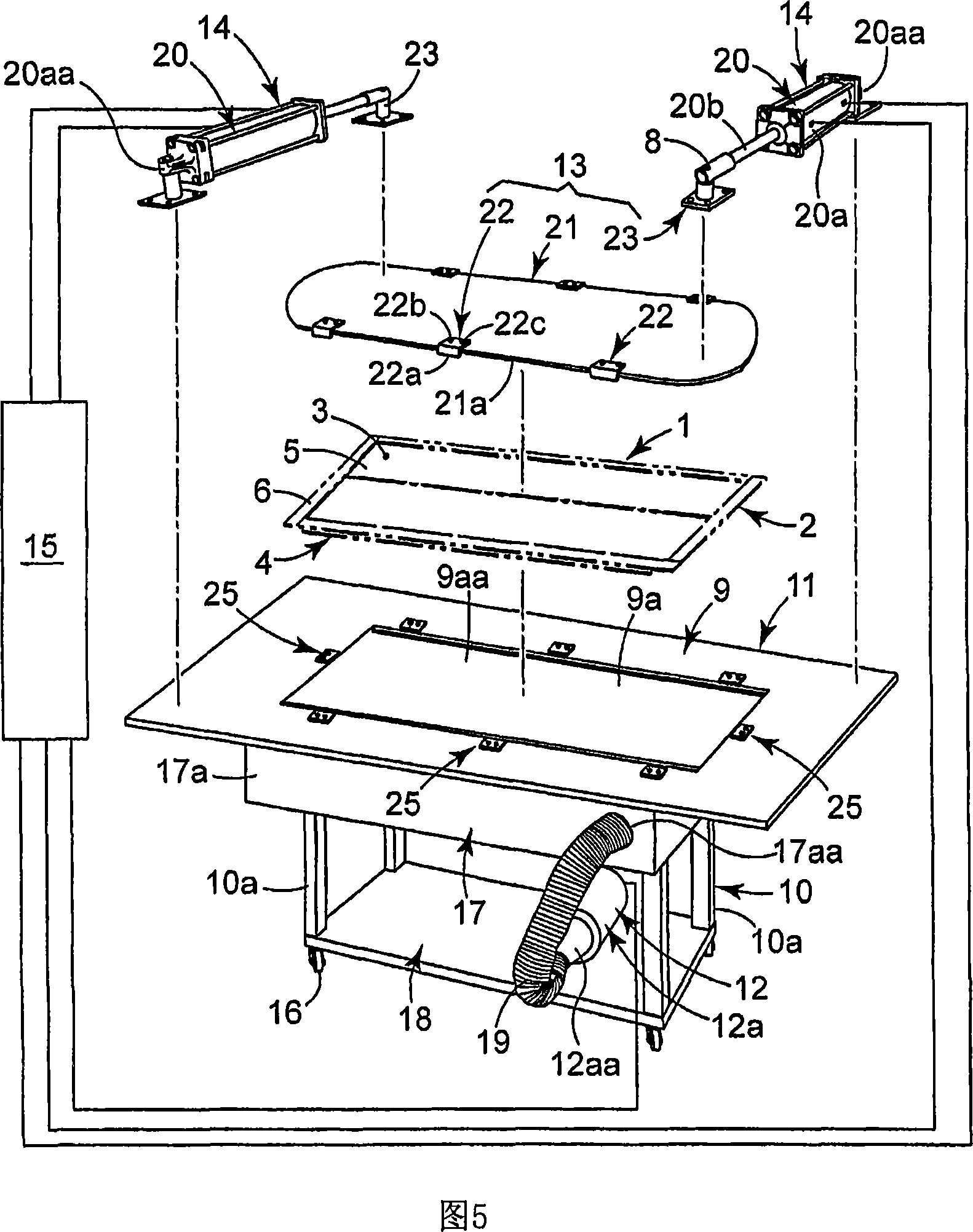

[0025] Embodiments of the present invention are described below with reference to FIG. 5 to FIG. 8 .

[0026] FIG. 5 is a schematic diagram of a separation device for a plasma display panel assembly according to the present invention.

[0027] 6 is a partially enlarged perspective view of a plasma display panel assembly separation device according to the present invention.

[0028] As shown in Fig. 5, the separating device of the plasma display panel assembly according to one embodiment of the present invention comprises: workbench 11, it comprises upper plate 9 and support upper plate 9 (that is, the upper plate of support plasma display panel assembly 1) The support area 10, the PDP assembly has the PDP glass panel 2 connected to the aluminum frame 4 through the medium heat conduction pad 5 or adhesive tape 6, and the workbench restricts the horizontal movement of the aluminum frame 4 through at least a part of the upper plate; the heater unit 12, It is located on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com