Series connected type machine overshoes

A tandem, shoe cover technology, applied in applications, clothing, hangers, etc., can solve the problems of high failure rate, unable to guarantee 100%, high quality requirements for machine shoe covers, etc. The effect of high set rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

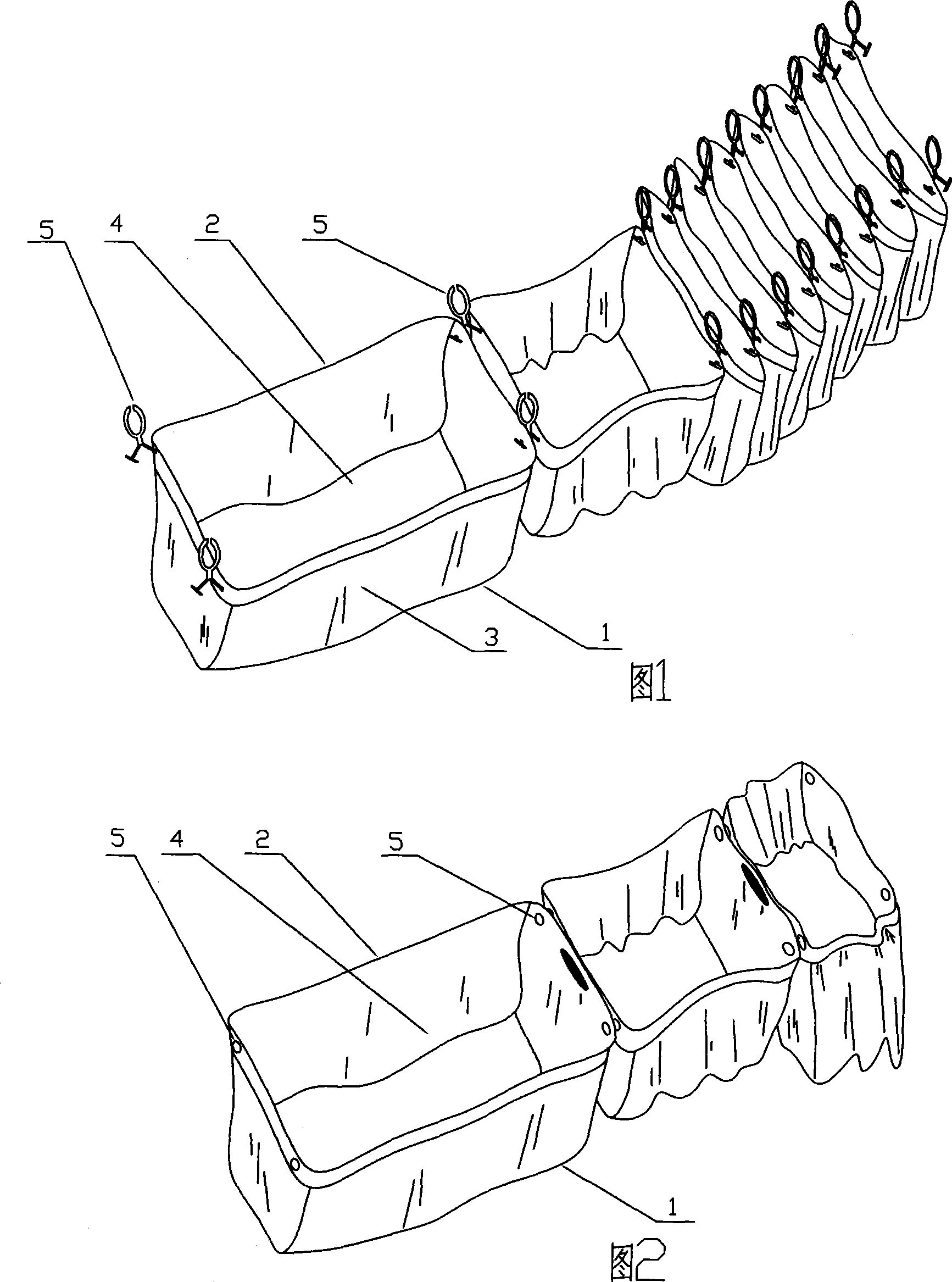

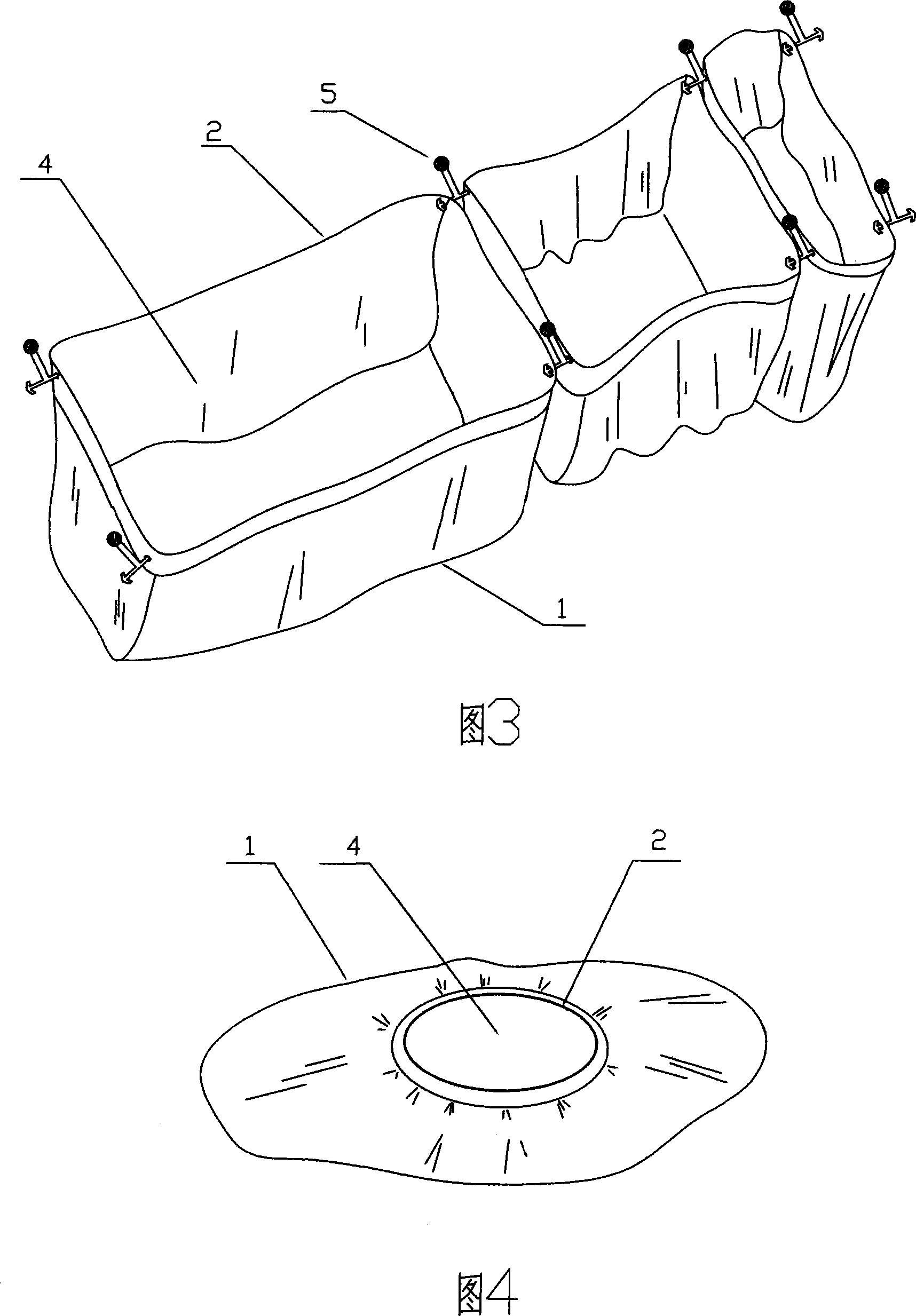

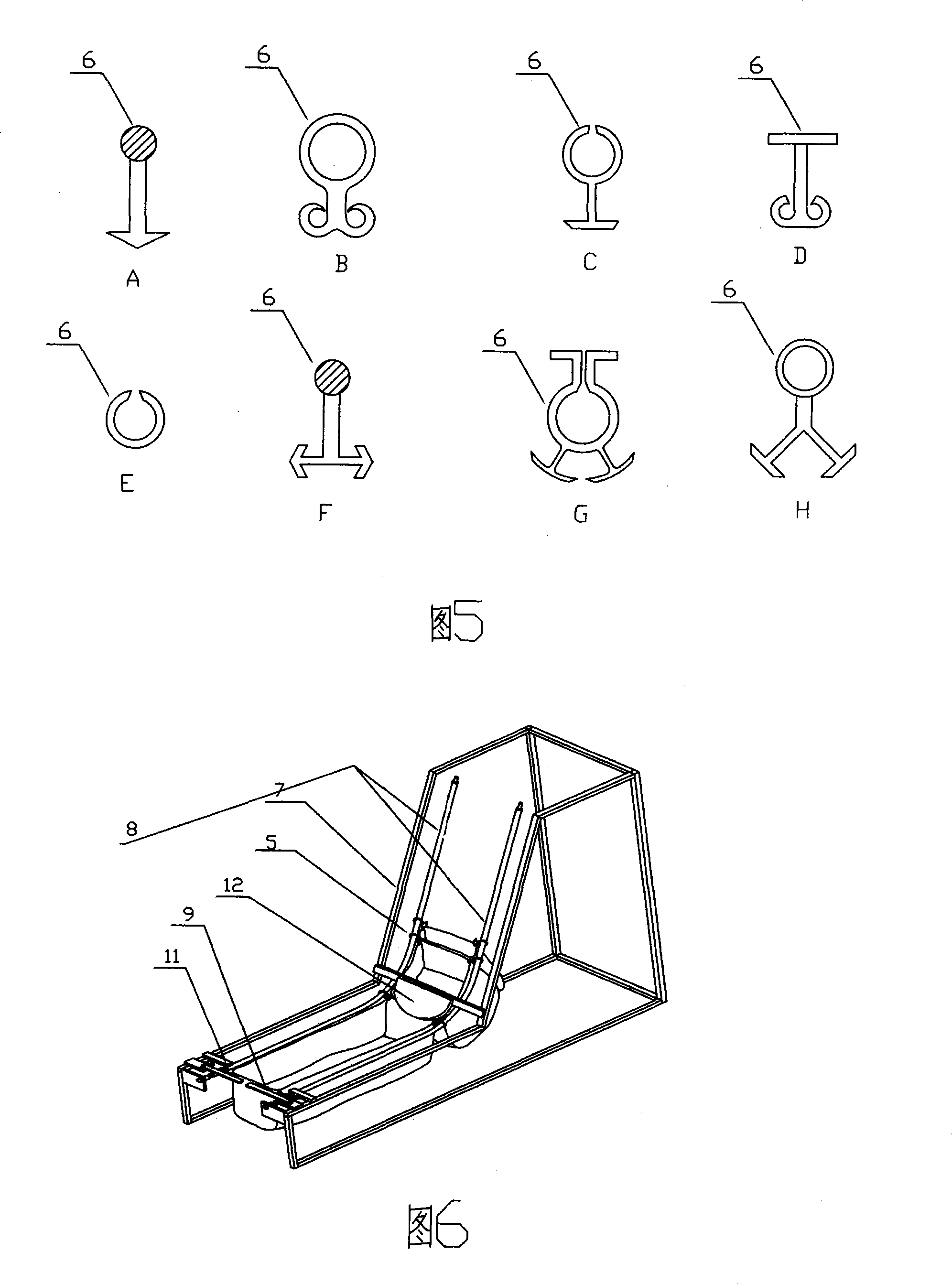

Embodiment 1

[0029] As shown in Figure 6 and Figure 9, the shoe cover body 3 is slidably fixed on the shaft-shaped shoe cover feeding guide rail 8 of the automatic shoe cover machine through the open ring shoe cover sliding connector 5, and the first shoe cover is pre-drawn to the feeding guide rail 8 At the exit of the frame 7 at the front end, and the slide connector 5 on it is pulled past the position of the first stopper 11, and its tail is positioned behind the second stopper 12, because the stopper 11 and the first stopper Two stoppers 12 are baffle plates made of elastic materials, which have certain resistance and are sufficient to overcome the pulling force of the shoe cover rubber pulled apart, so the shoe cover can be kept in an open state for use, and the pin is put into the In the shoe cover bag-shaped opening 4 that is pulled open, then the pin is dragged out from the front end outlet of the frame 7 along the shoe cover feeding guide rail 8 parallel to the rear, and now the sl...

Embodiment 2

[0031] As shown in Figure 7 and Figure 10, its working process is roughly the same as that of Embodiment 1, the difference is that there is no additional sliding connector for the shoe cover in series, and the sliding connector 5 is the perforation on the shoe cover body 3, and the shoe cover The connection with the shoe cover is set on the shoe cover feeding shaft-shaped guide rail 8 through its perforation, the linkage swing arm 9 is a single-piece swing arm structure, and the first stopper 11 and the second stopper 12 are both hinged. The set single pendulum structure, the second stopper 12 is connected with the linkage swing arm 9 through the transmission rod 13, the shoe cover is out of the series state and the follow-up shoe cover remains open, which no longer overcomes the second stopper 12 The resistance of the elastic baffle is realized by the linkage of the swing arm 9 and the linkage of the second stopper 12 to flip release and return blocking.

Embodiment 3

[0033] As shown in Figure 8 and Figure 11, its working process is the same as that of Embodiment 1, the difference is that: ①The frame 7 is a horizontal structure, ②The shoe cover feeding guide rail 8 is a chute-shaped structure, ③The shoe cover is slidingly connected The sliding and fixing part 6 of the piece 5 is in the shape of a hanging bead, and ④ the first stopper 11 is a single pendulum structural member hinged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com