Cold pilger mill crankshaft-dual eccentric center quality level balance method

A cold-rolled pipe mill, high-quality technology, applied to the driving device for metal rolling mills, metal rolling, metal rolling, etc., can solve the problems of unsatisfactory balance effect, high maintenance cost, and difficult installation, etc., to achieve Simple structure, low maintenance cost, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

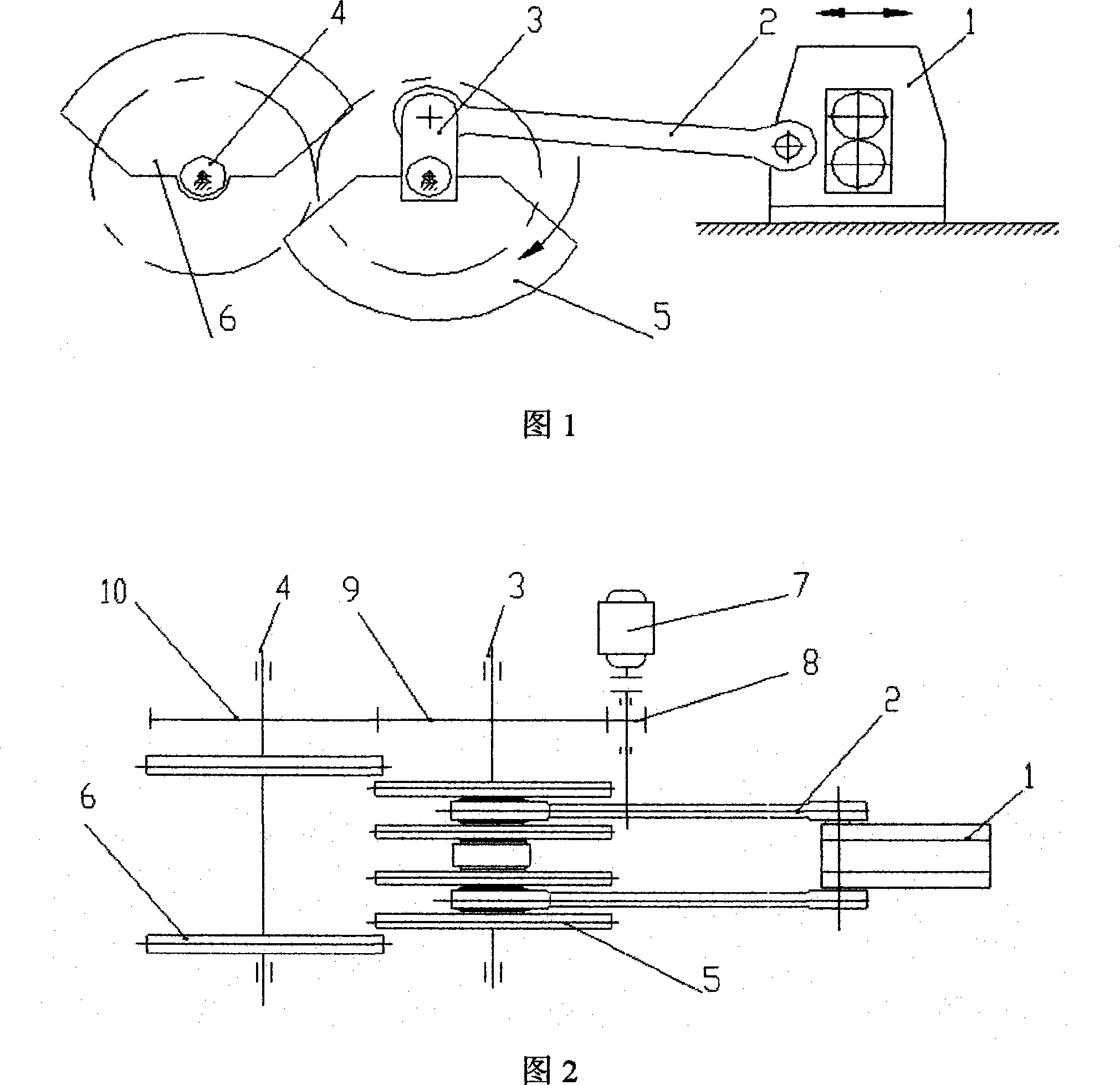

[0017] As shown in Figures 1 and 2, the output shaft of the motor 7 is connected to the pinion 8, and the pinion 8 meshes with the large gear 9 on the crankshaft. The large gear 9 on the crankshaft is connected to the crankshaft 3 on the one hand, and the crankshaft Bull gear 9 drives crankshaft 3 to rotate; By crankshaft 3, be connected with fan-shaped block (eccentric mass) 5 on the crankshaft of interval distribution at the same time, through two connection with crankshaft 3 and between the fan-shaped block (eccentric mass) 5 on crankshaft The rod 2 connects the crankshaft 3 with the frame 1, and the crankshaft 3 pulls the frame 1 through two connecting rods 2 to realize reciprocating motion.

[0018] On the other hand, the large gear 9 on the crankshaft on the crankshaft 3 meshes with the large gear 10 on the balance shaft, and the large gear 10 on the balance shaft is connected with the balance shaft 4, and the sector block on the balance shaft is connected on the balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com