Minicar two-wheeled drive and four-wheel drive power mechanism

A technology for four-wheel drive and micro-cars, applied in control devices, vehicle parts, transportation and packaging, etc., can solve problems such as inability to drive, inconvenient travel, driving wheels stuck in mud, etc., to reduce wear, improve passability, and enhance climbing The effect of slope ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

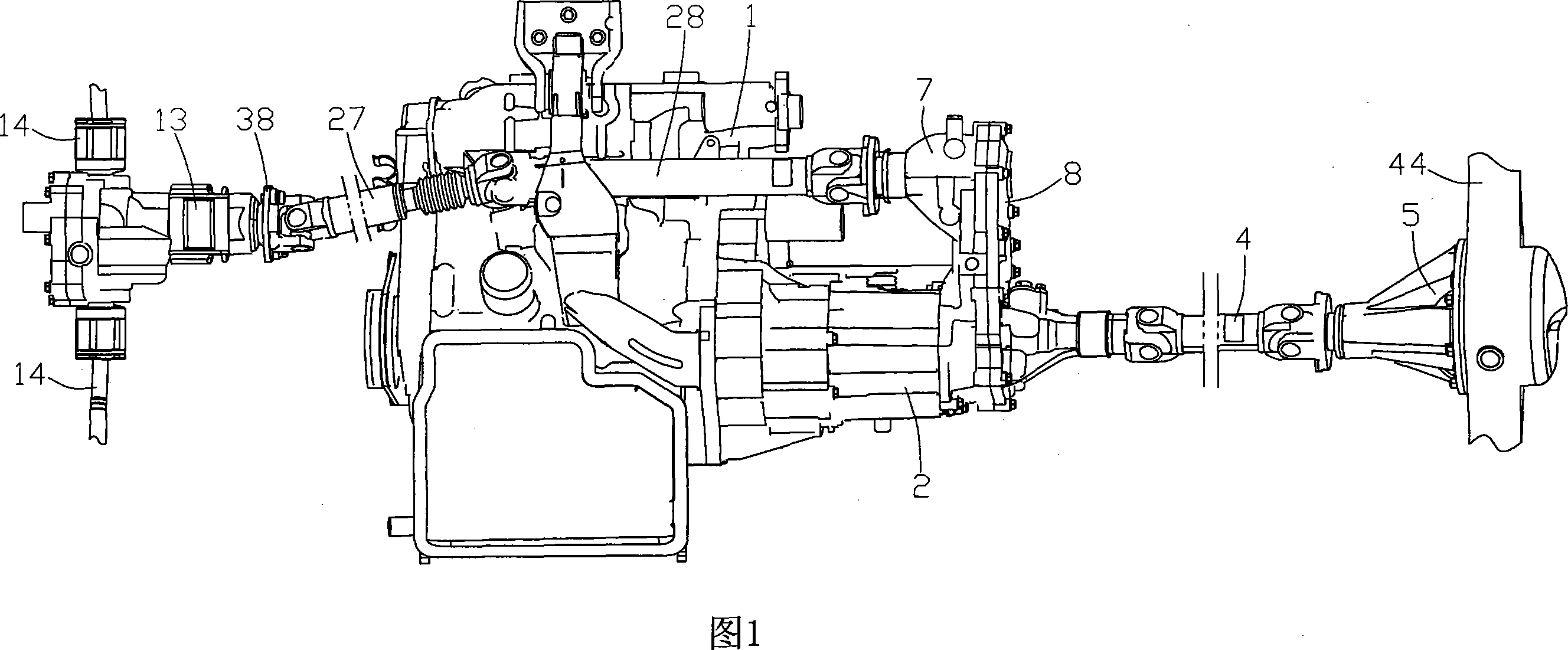

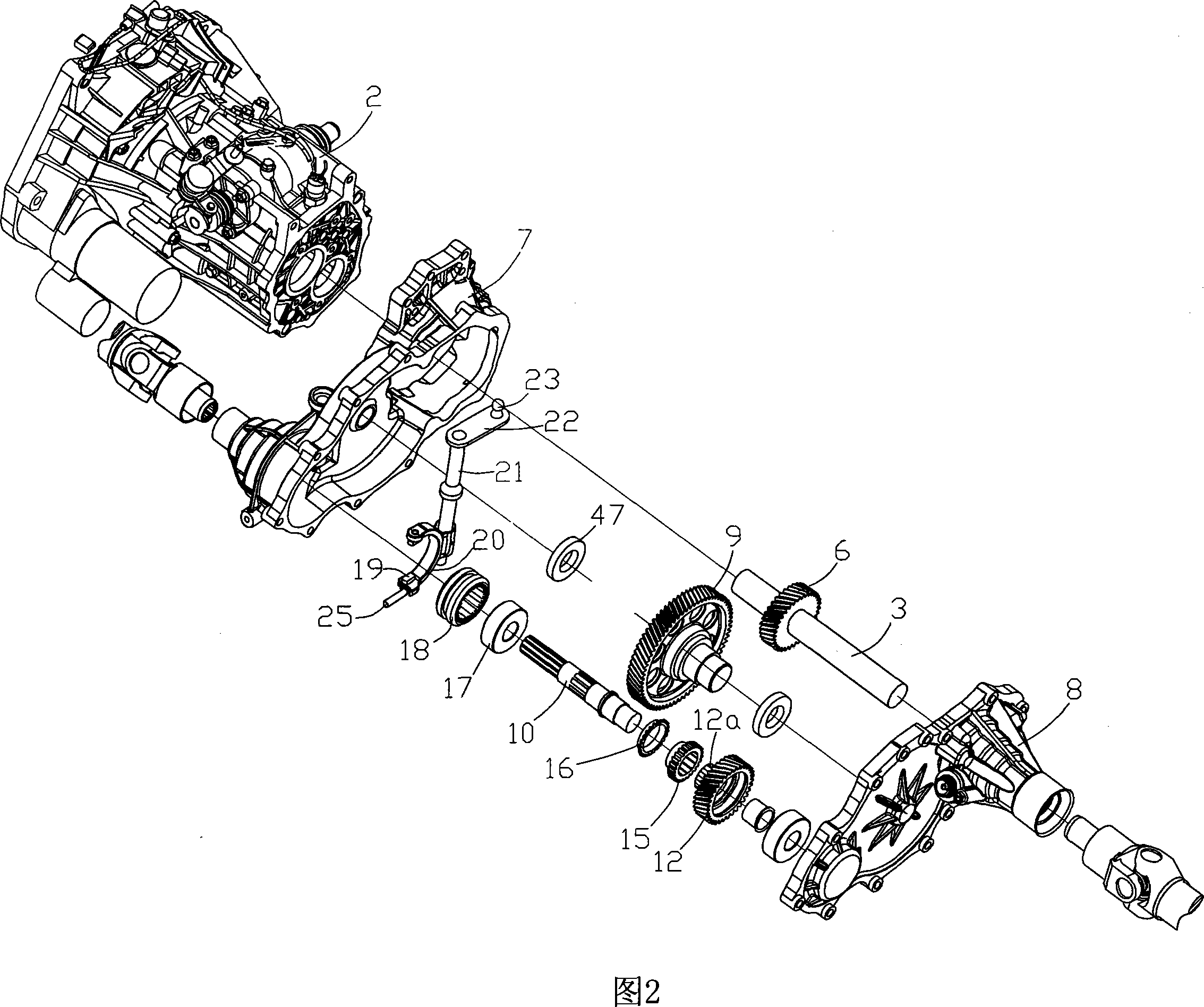

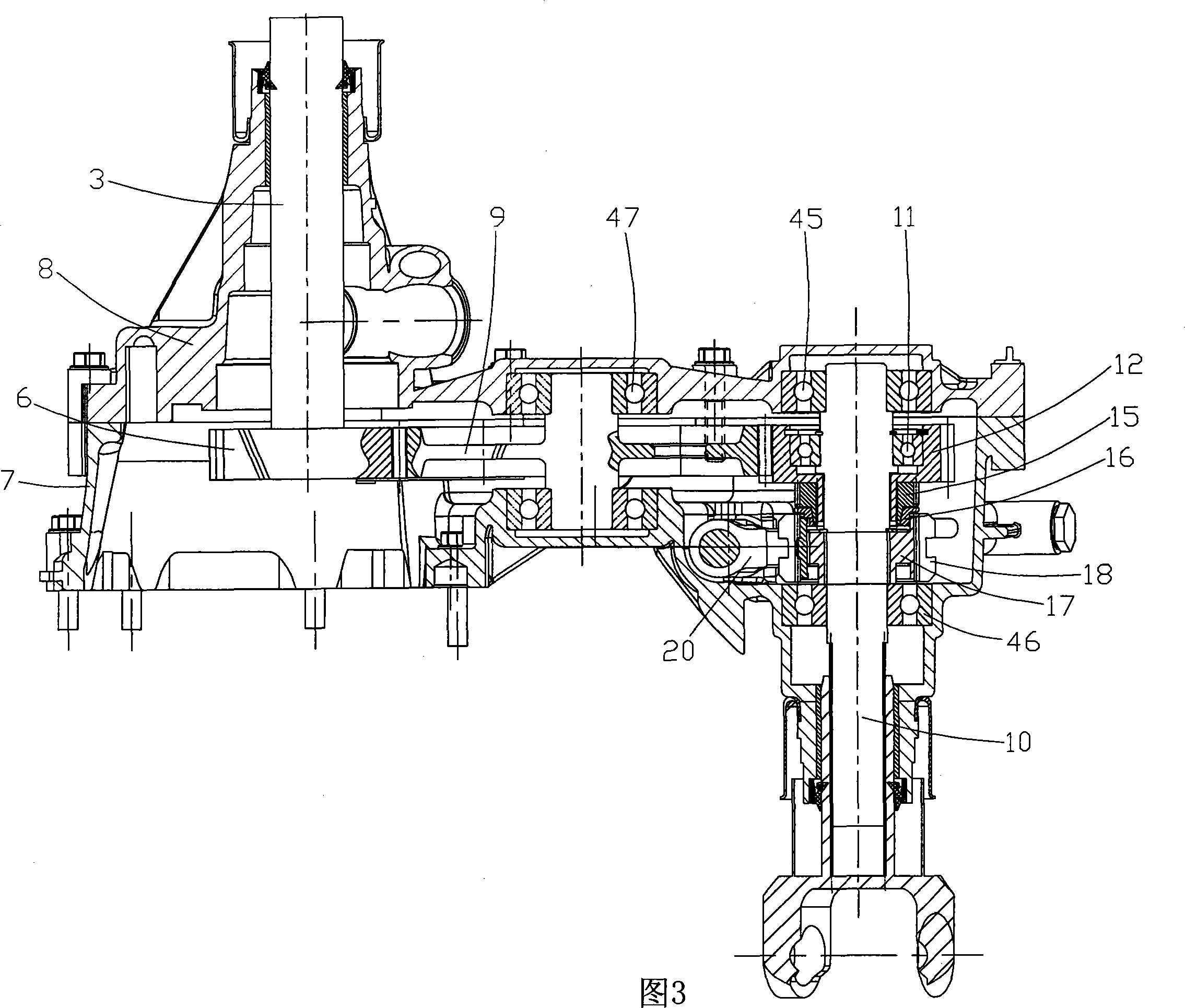

[0027] As shown in FIG. 1 , FIG. 2 and FIG. 3 , the gearbox 2 is installed at the rear end of the engine 1 , and the input shaft of the gearbox 2 is connected with the output shaft of the engine 1 . The transfer case is located at the tail of the gearbox 2, and is formed by docking the transfer case front cover 7 and the transfer case rear cover 8, and the two are fixed by bolts. The front part of one side of the transfer case front cover 7 is integrally formed with a hollow truncated cone, and the front end face of the other side of the transfer case front cover 7 is adapted to the shape and size of the tail end face of the gearbox 2, so that the splitter can be separated by bolts. The moving case is fixed on the gearbox 2. The output shaft 3 of the gearbox 2 passes through the transfer case and protrudes from the hollow cone formed integrally at the rear o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap