Double rubberbands four sliding rails arrow type ejection mechanism

A slide rail and rubber band technology is applied in the field of mechanical launchers, which can solve the problems of narrow application fields, limited application scope, and inability to adjust the position of objects to be launched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

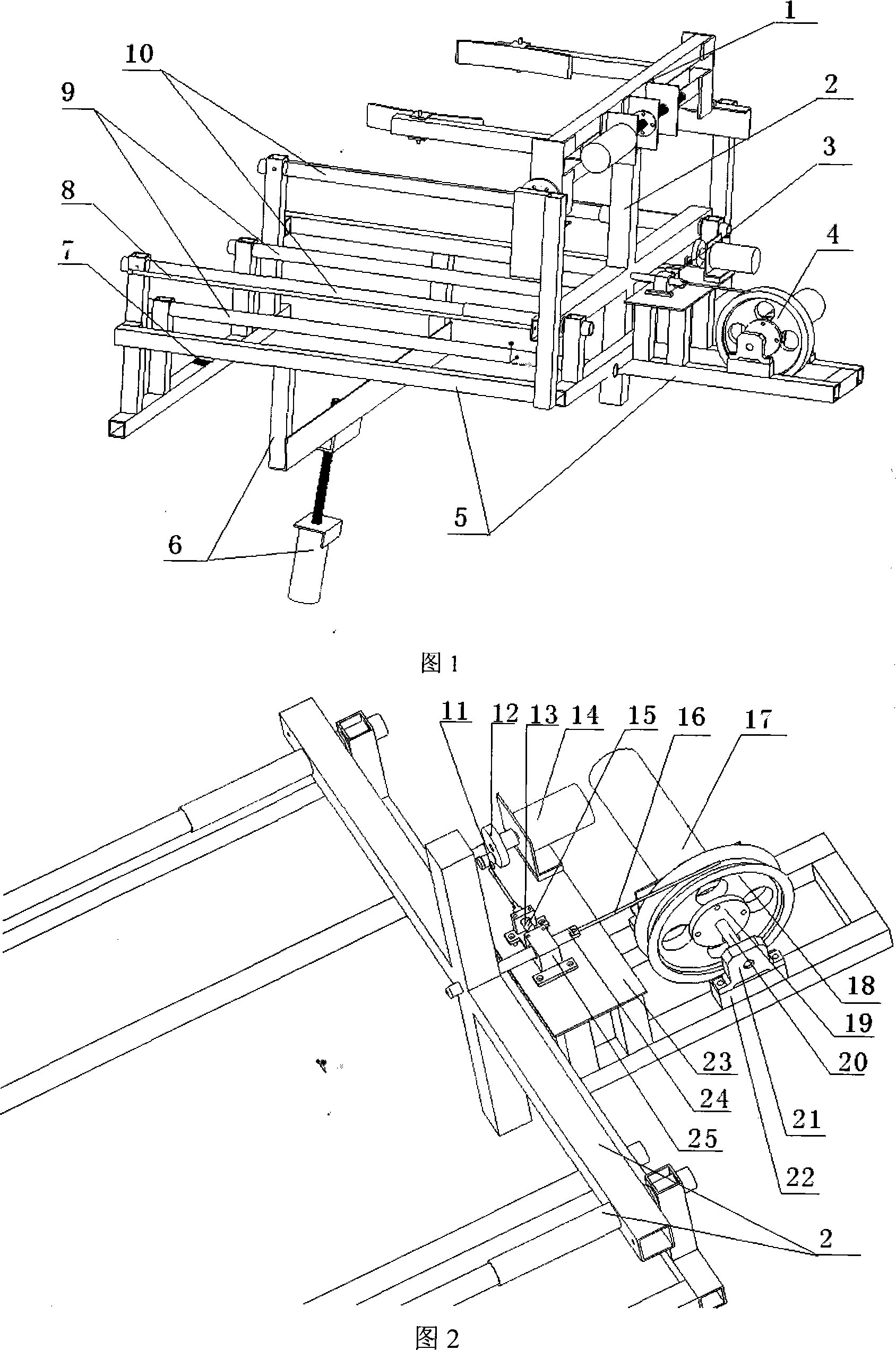

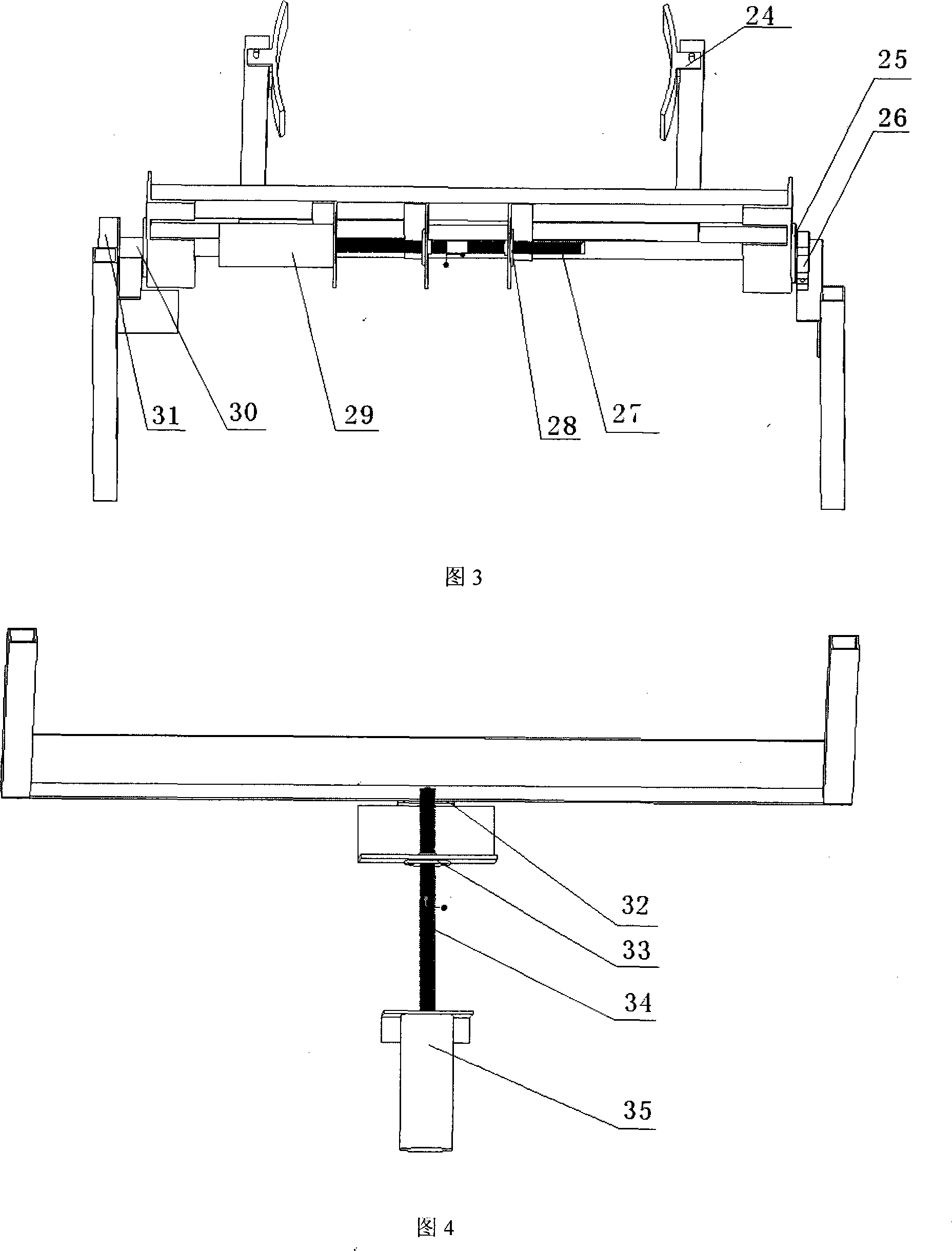

[0027] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0028] The present invention includes a frame 5 , a launch rail 10 , a launch track 9 , an angle adjustment device 6 , a trigger device 3 , a wire take-up and release device 4 and an overturning manipulator 1 . Wherein the winding wheel 18 is connected to the bearing seat 21 through the shaft coupling 20, one end is connected to the winding motor 17, fixed on the frame 5, and the axis is parallel to the frame by adjusting the height of the cushion block 22; the trigger device 3 The motor 14 is fixed on the support plate 23 through angle aluminum, the support plate 23 is connected with the frame 5 through 4 aluminum alloy square tubes, the pin pulling motor 14 drives the cam mechanism 12 to pull the steel wire 13, and the other end of the steel wire 13 is connected to the bayonet pin 15 connected; the manipulator 1 needs to realize two degrees of freedom of graspin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com