A Soft Mold-Assisted Integral Forming Method of Composite Bearing Tube Containing Light-blocking Ring

A composite material and overall molding technology, which is applied in the field of soft mold-assisted overall molding of composite material load-bearing cylinders with halo-blocking rings, can solve the problems of increased product weight, many fasteners, and low efficiency, and solve the problem of connection strength, Guarantee the size requirements of the product and avoid the effect of bulges or pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

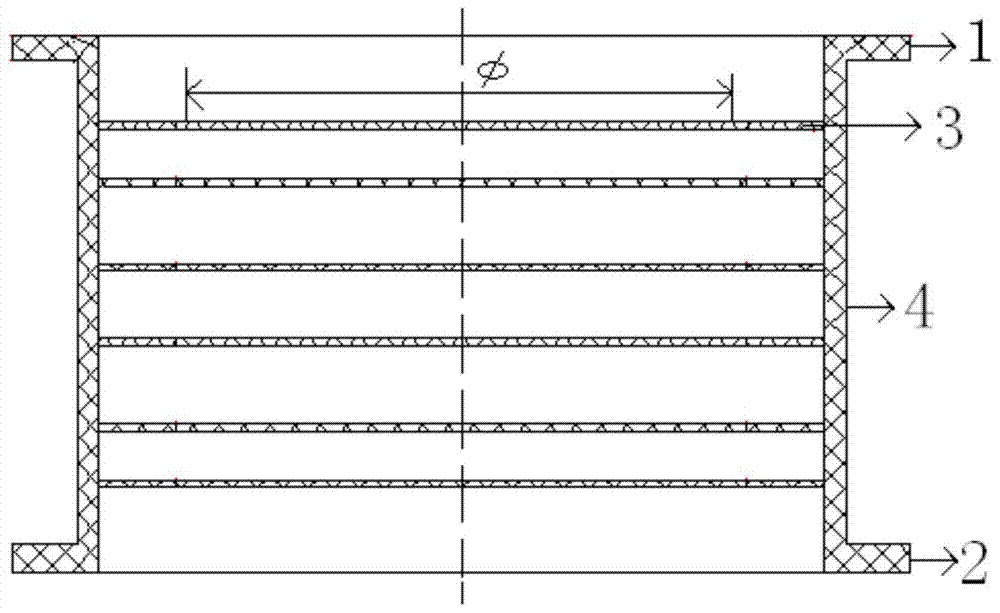

[0031] like figure 1 As shown, the load-bearing tube of composite material includes a load-bearing tube skin 4, the upper and lower sides of the load-bearing tube skin 4 are valgus upper frame 1 and lower end frame 2, and six light blocking rings 3 are arranged inside the load-bearing tube skin 4.

[0032] Dimensions: The outer diameter of the upper and lower frames is 741mm, and the inner diameter is 693mm; the inner diameter of the skin is 600mm~602mm;

[0033] According to the present invention, a soft mold-assisted integral molding method of a composite material load-bearing cylinder containing a light-blocking ring includes the following steps:

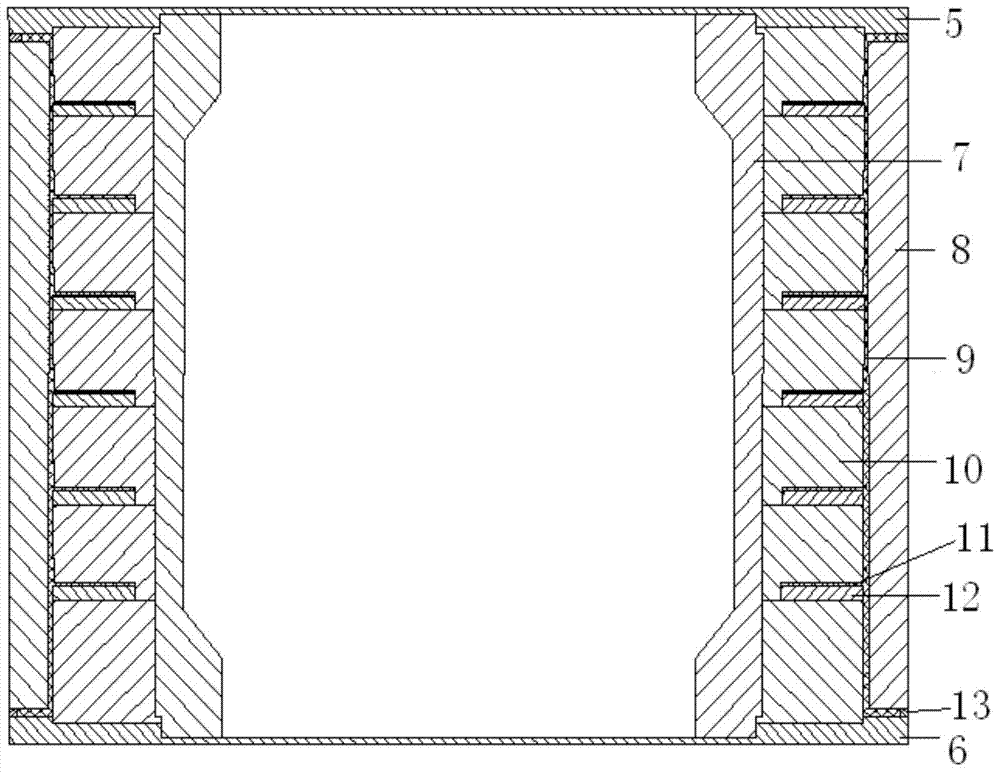

[0034] (a) Silicone rubber soft mold preparation

[0035] The silicone rubber soft mold 12 is used for forming the light blocking ring, and it is prepared by pouring silicone rubber; specifically, the silicone rubber liquid is degassed, poured, cured at room temperature for 48 hours, and heat treated after demoulding to obtain t...

Embodiment 2

[0051] like figure 1 As shown, the load-bearing tube of composite material includes a load-bearing tube skin 4, the upper and lower sides of the load-bearing tube skin 4 are valgus upper end frame 1 and lower end frame 2, and seven light blocking rings 3 are arranged inside the load-bearing tube skin 4.

[0052] Dimensions: The outer diameter of the upper and lower frames is 741mm, and the inner diameter is 693mm; the inner diameter of the skin is 600mm~602mm; the thickness of the halo is 2mm, the thickness of the skin is 4mm, and the thickness of the upper / lower frame is 6mm.

[0053] According to the present invention, a soft mold-assisted integral molding method of a composite material load-bearing cylinder containing a light-blocking ring includes the following steps:

[0054] (a) Silicone rubber soft mold preparation

[0055] The silicone rubber soft mold 12 is used for forming the light-blocking ring, which is prepared by pouring silicone rubber; specifically, the silic...

Embodiment 3

[0070] like figure 1 As shown, the load-bearing tube of composite material includes a load-bearing tube skin 4, the upper and lower sides of the load-bearing tube skin 4 are the upper end frame 1 and the lower end frame 2 turned outward, and eight light blocking rings 3 are arranged inside the load-bearing tube skin 4 . The thickness of the halo ring is 0.3mm.

[0071] According to the present invention, a soft mold-assisted integral molding method of a composite material load-bearing cylinder containing a light-blocking ring includes the following steps:

[0072] (a) Silicone rubber soft mold preparation

[0073] The silicone rubber soft mold 12 is used for forming the halo ring, which is prepared by pouring silicone rubber; specifically, the silicone rubber liquid is defoamed, poured, cured at room temperature for 12 hours, and heat-treated after demolding to obtain a silicone rubber soft mold. The heat treatment process is as follows: Incubate at 170°C for 12h.

[0074] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com