Apparatus for measuring the position of a piston in a cylinder

An internal piston and cylinder technology, applied in the field of position sensors, can solve the problems of reduced measurement accuracy, reduced sensor life, damage, etc., and achieve accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

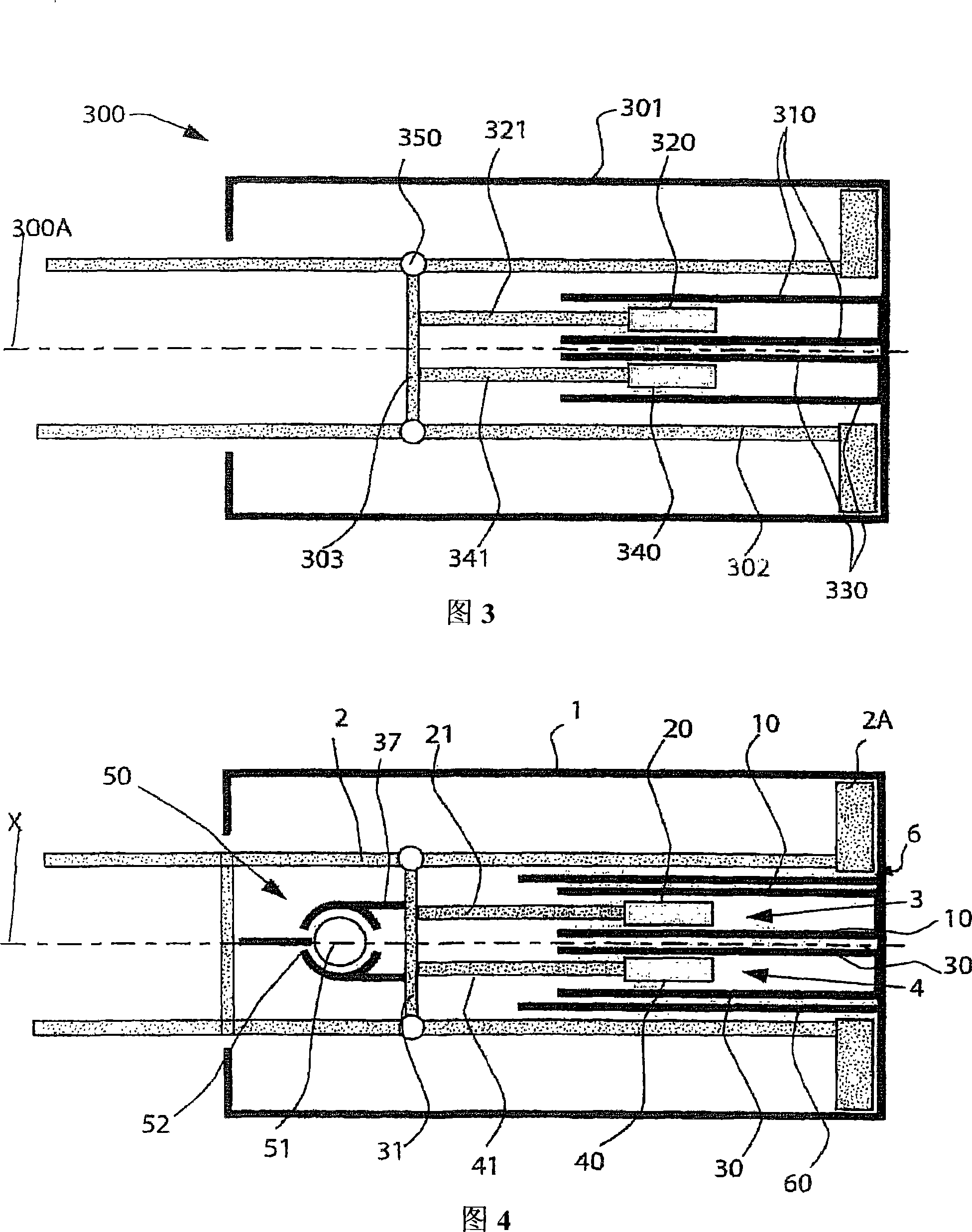

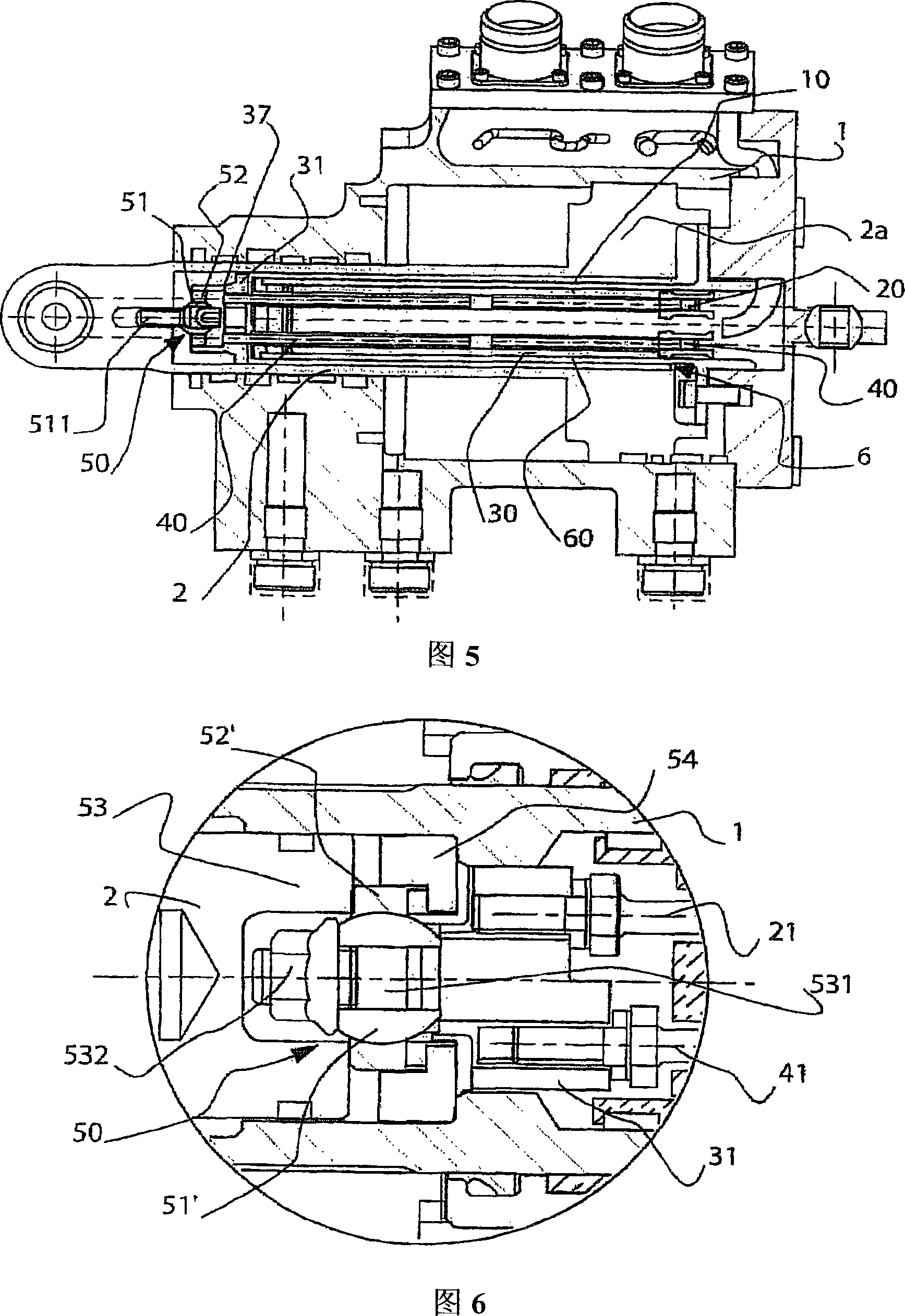

[0035] Referring to FIG. 4 , the lifting device comprises a cylinder 1 extending along the X-axis, within which a piston 2 is arranged, the piston 2 comprising a piston head 2A whose outer diameter corresponds to the inner diameter of the cylinder 1 . The lifting device comprises means for measuring the position of the piston 2 relative to the cylinder 1 comprising two position sensors 3, 4 of the LVDT type.

[0036] Each sensor 3,4 includes a magnetic core 20,40 which cooperates with a transformer 10,30 as previously described. The transformers 10, 30 are arranged longitudinally along the axis X inside the cylinder 1 and fixed at the downstream end of the cylinder. The transformers 10, 30 are enclosed in a protective sheath 60, which extends longitudinally inside the cylinder 1, and whose downstream end is fixed integrally with the downstream end of the cylinder 1. The protective sleeve 60 extends concentrically inside the piston 2 and comprises, at its downstream end, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com