Liquid heating container

A liquid heating container and liquid technology, which is applied to electric heating devices, cooking utensils, multi-unit cooking utensils, etc., can solve the problems of no liquid covering and dry burning, and achieve the effects of long service life, prevention of dry burning, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The liquid heating container of the present invention includes a coffee pot, an electric kettle, a water heater, etc., but is not limited to the above-mentioned heating containers.

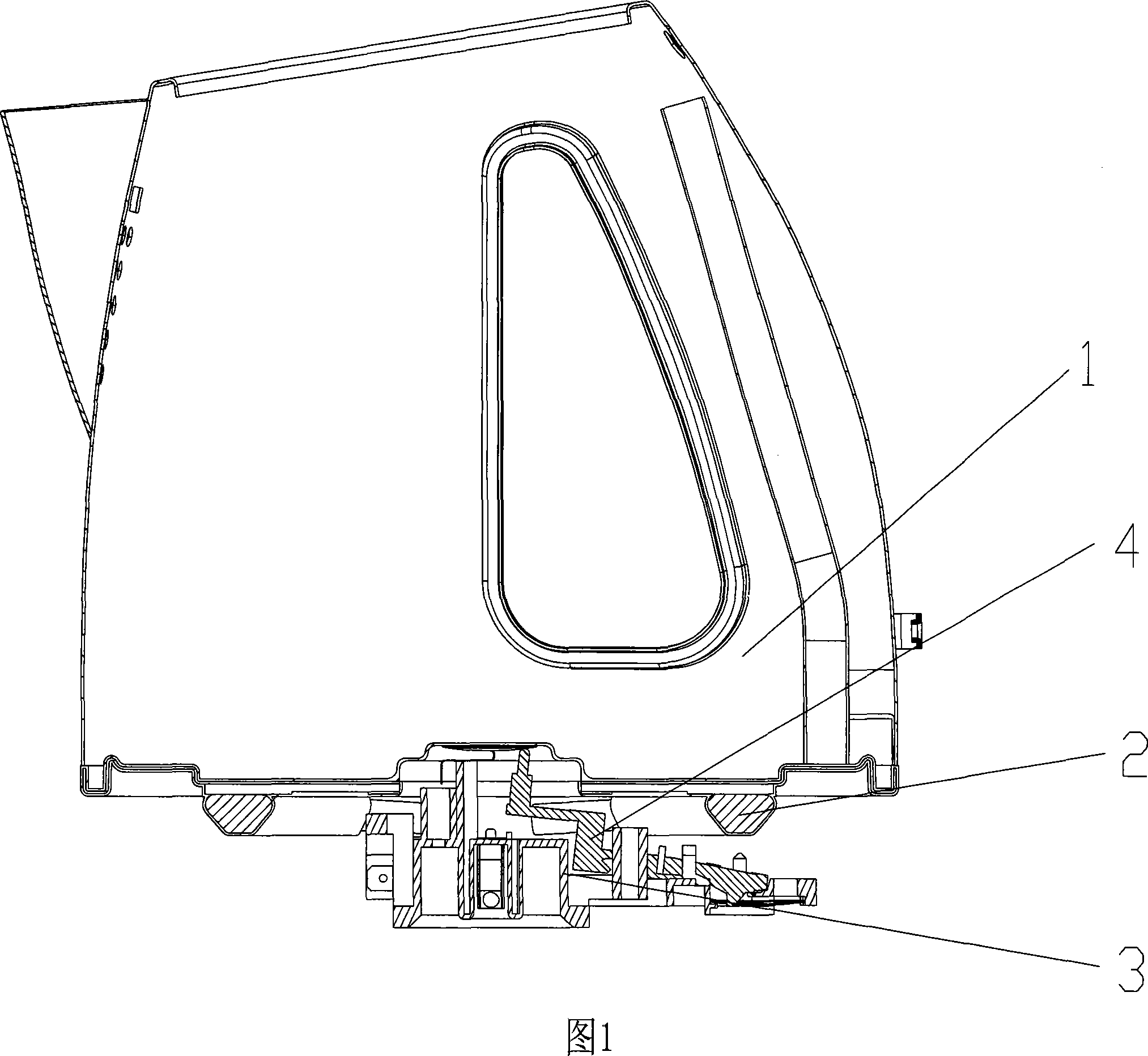

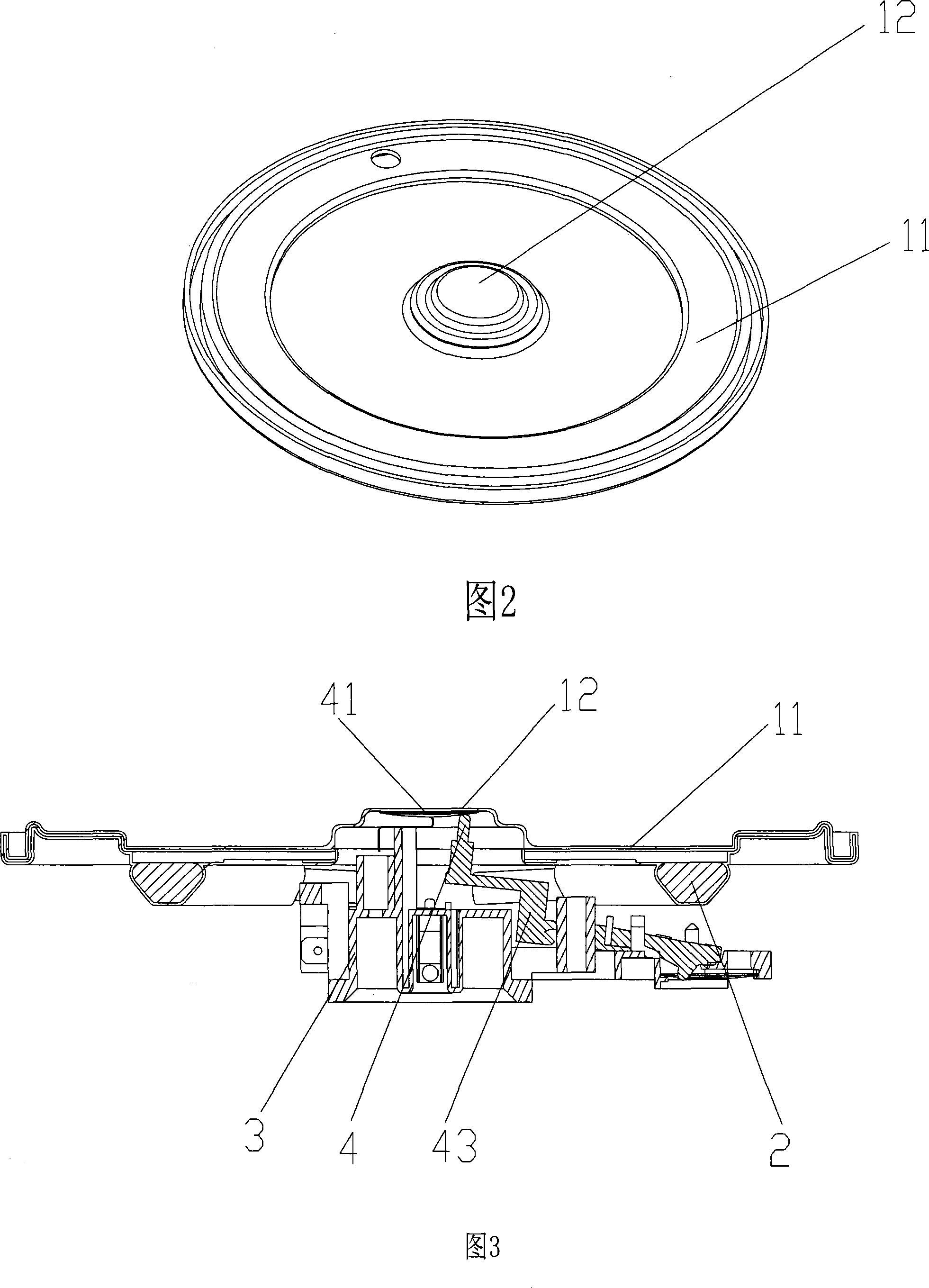

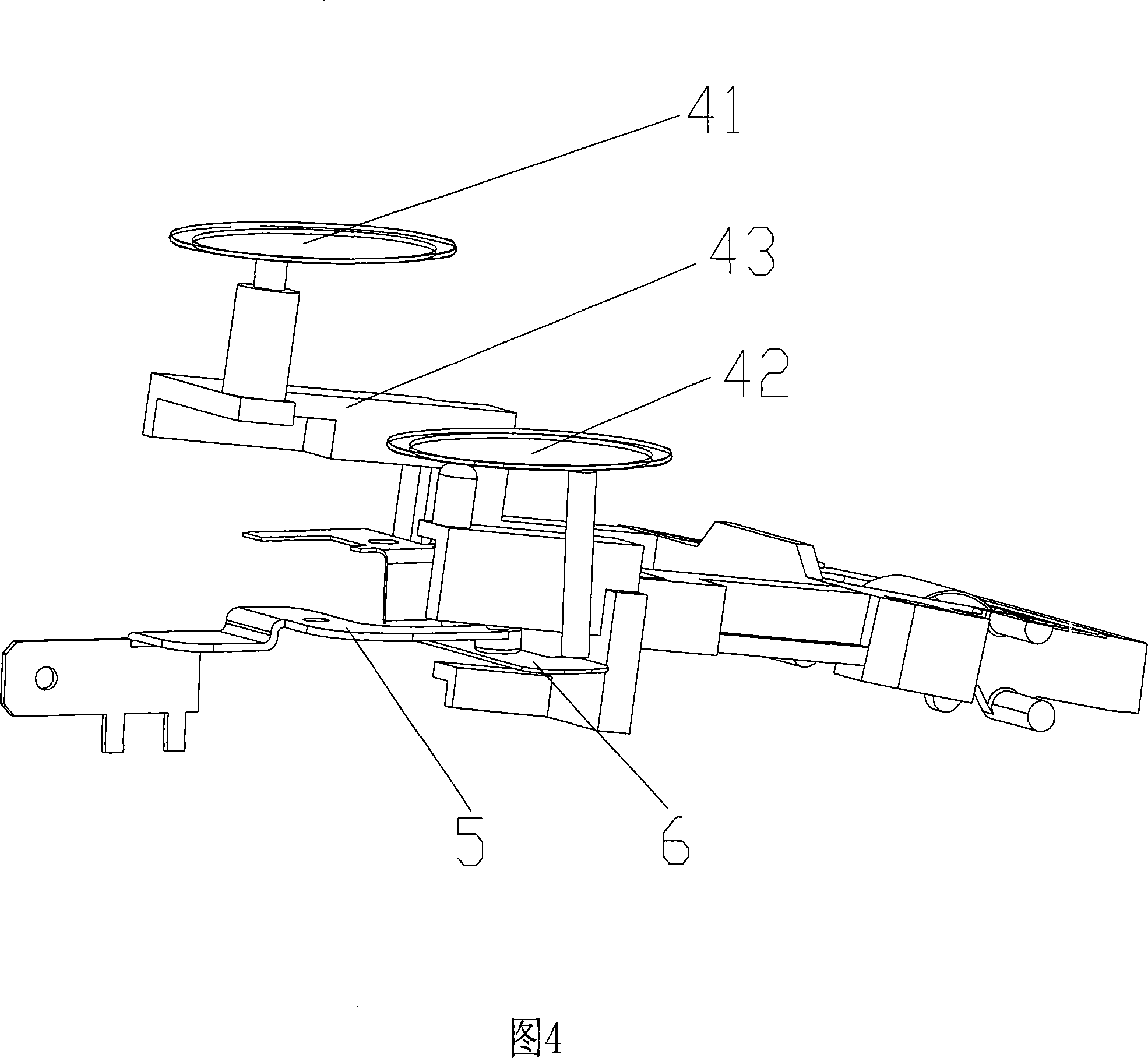

[0026] Take electric kettle as example below, the present invention is described in detail. Please refer to Figures 1 to 4, the electric kettle of the present invention includes a container body 1 for holding heated liquid, a heating device 2 for providing heat energy to the container body 1, a connector 3 for transmitting electrical signals, and a connector 3 for connecting The electrical switch contacts of the power supply and the heating device 2, and the thermal control assembly 4 for directly or indirectly controlling the electrical switch contacts, the heating device 2 is located at the lower end of the container main body 1, and is closely attached to the bottom 11 of the container main body 1. The control assembly 4 is in contact with the heating device 2 and is located below the he...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap