Punching technique for hypogynous metal bumper of heavy-duty car

A technology for heavy-duty vehicles and bumpers, applied in the field of auto parts stamping, can solve the problems of high mold maintenance costs, difficult forming, and cumbersome stamping process, so as to improve the product qualification rate, reduce the number of mold sets, and shorten the debugging cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

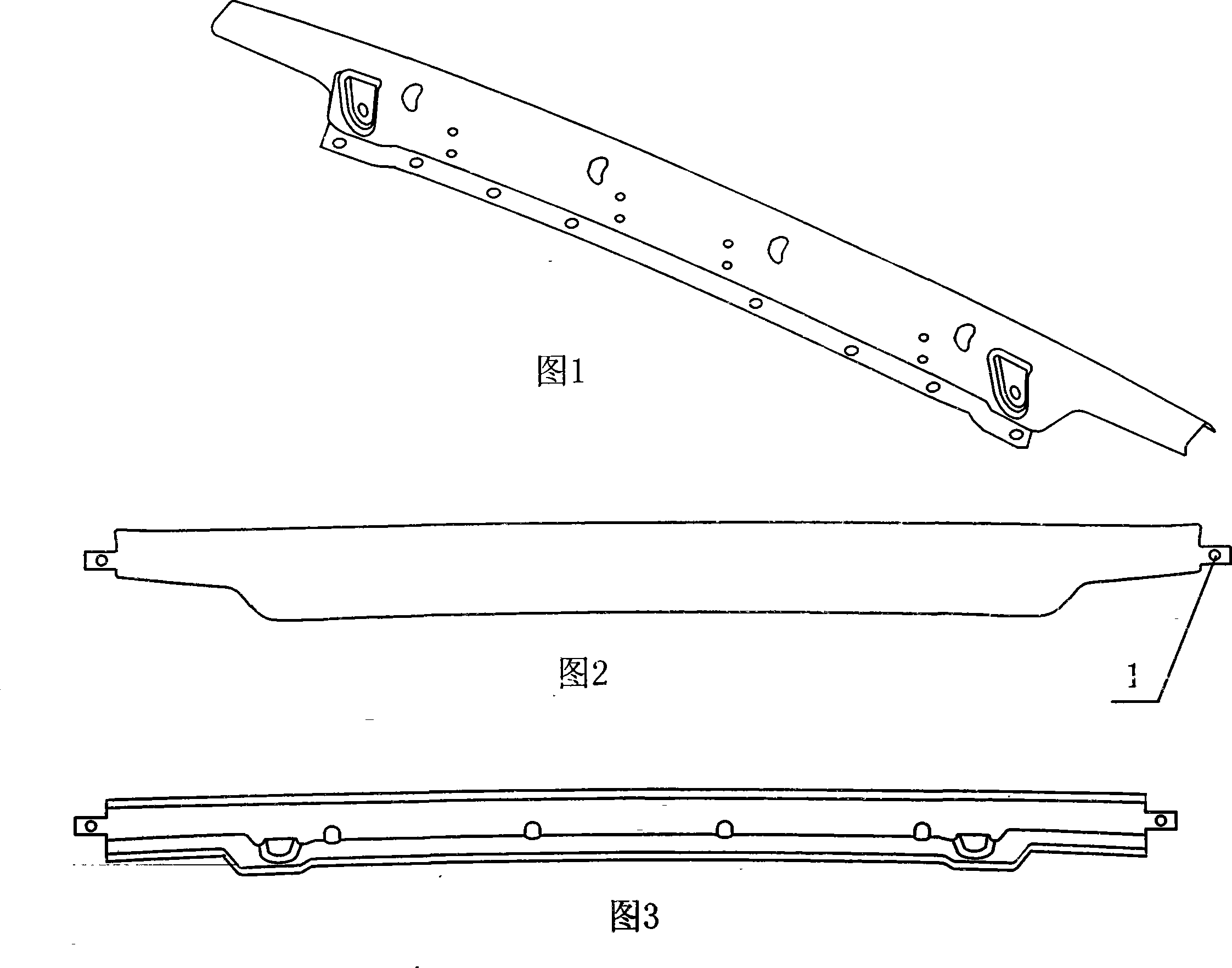

[0018] The structure of the lower metal bumper of a heavy-duty vehicle is shown in Figure 1, with holes on the front and side.

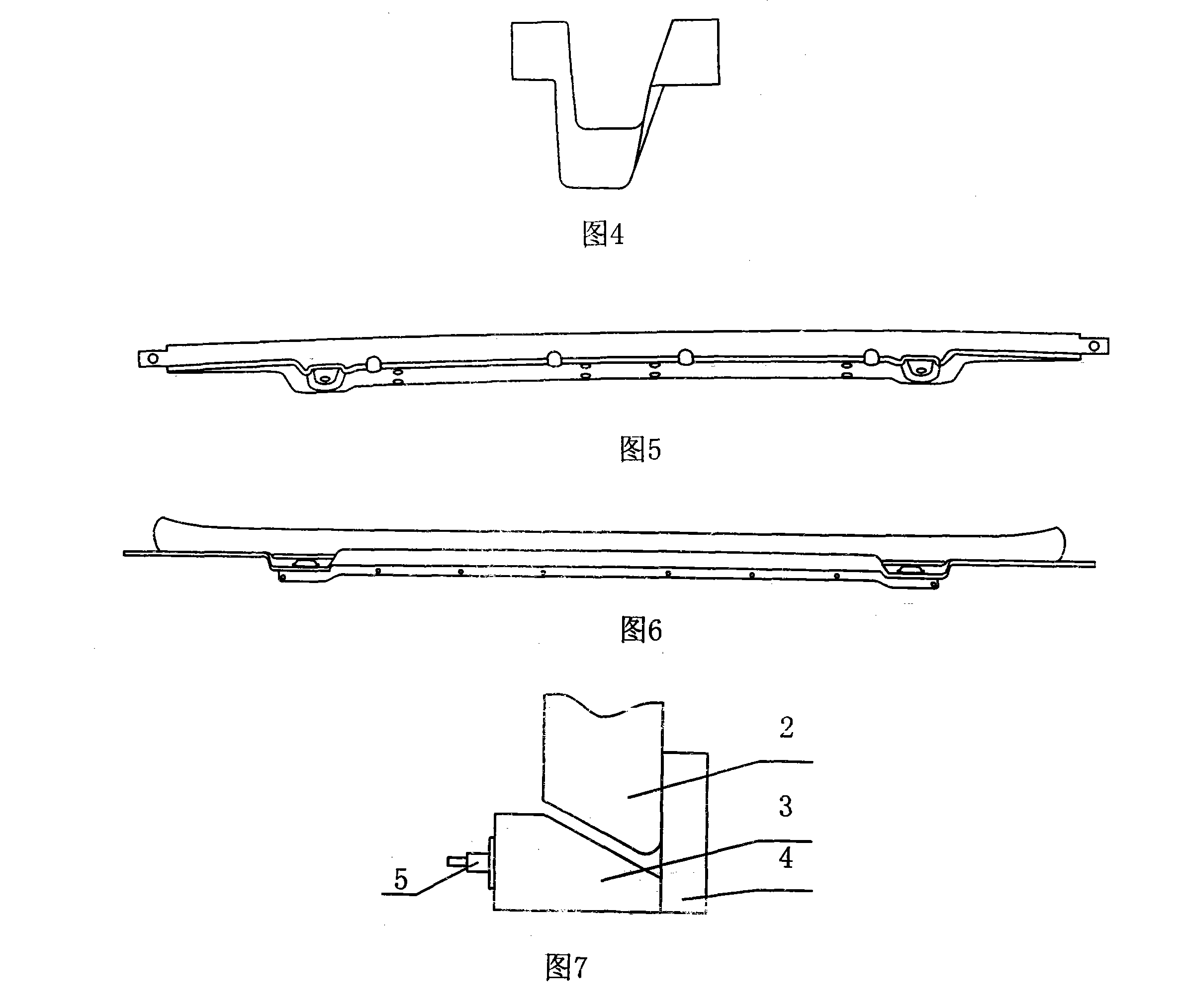

[0019] Since the lower metal bumper does not require high appearance quality, it is not necessary to adopt the usual deep drawing process. The deep drawing process needs to add more process supplements, and the excess process waste will be trimmed during trimming. According to the technique of the present invention, the blanking is first carried out, then forming is carried out, and finally trimming, punching and side punching are carried out to obtain the shape of the product. Specific steps are as follows:

[0020] (1) Blanking

[0021] Firstly, the blanking process is carried out, and the block material is punched to obtain the expanded shape of the product as shown in Figure 2. Due to the complexity of the expanded shape, the closed blanking method is adopted for blanking. Add process supplements during blanking, including the supplement of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com