Circular linear parking hosting device

A linear and circular technology, applied in the field of circular linear parking lifting devices, to achieve the effect of size reduction, overall structure reduction and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

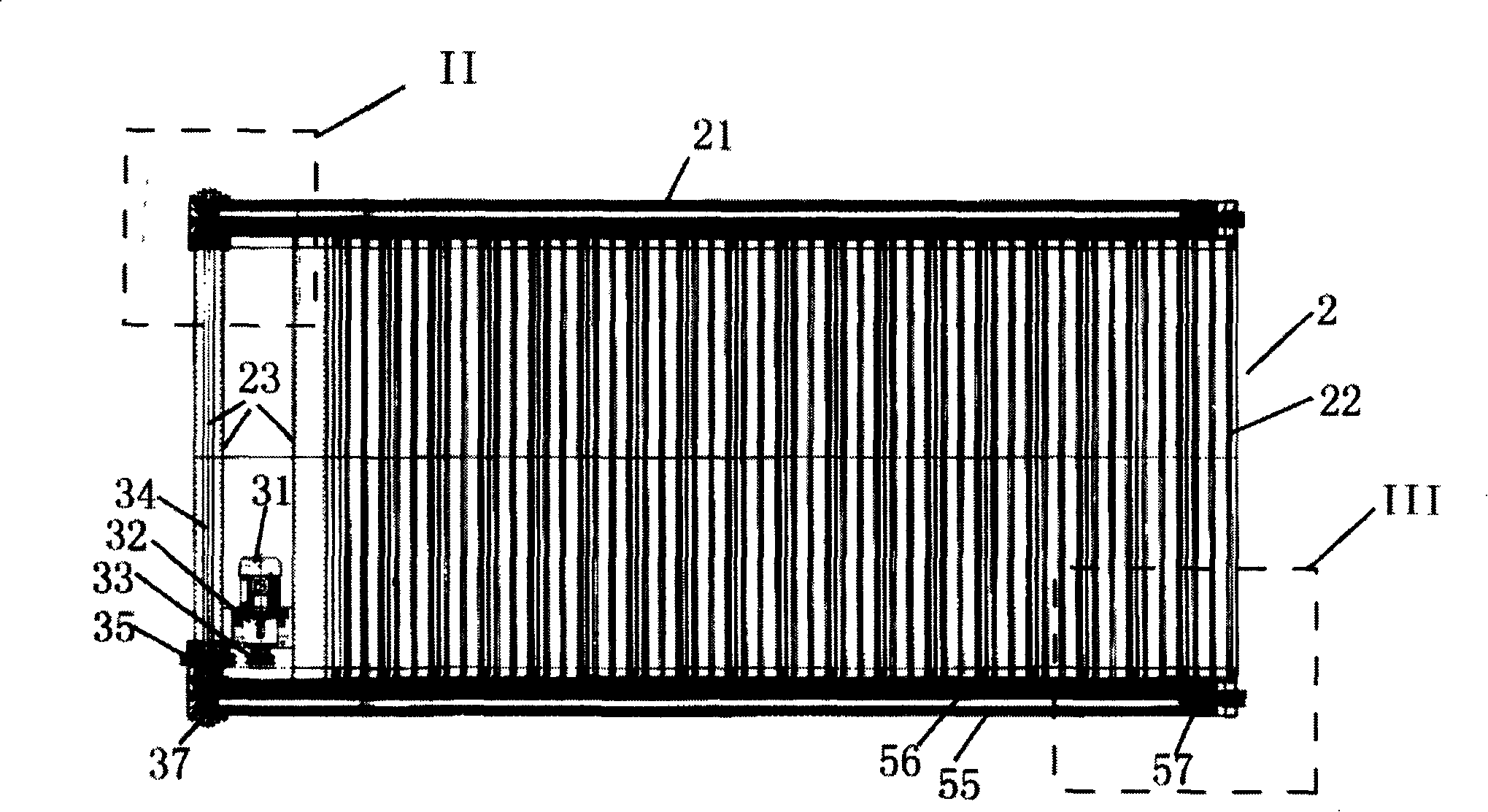

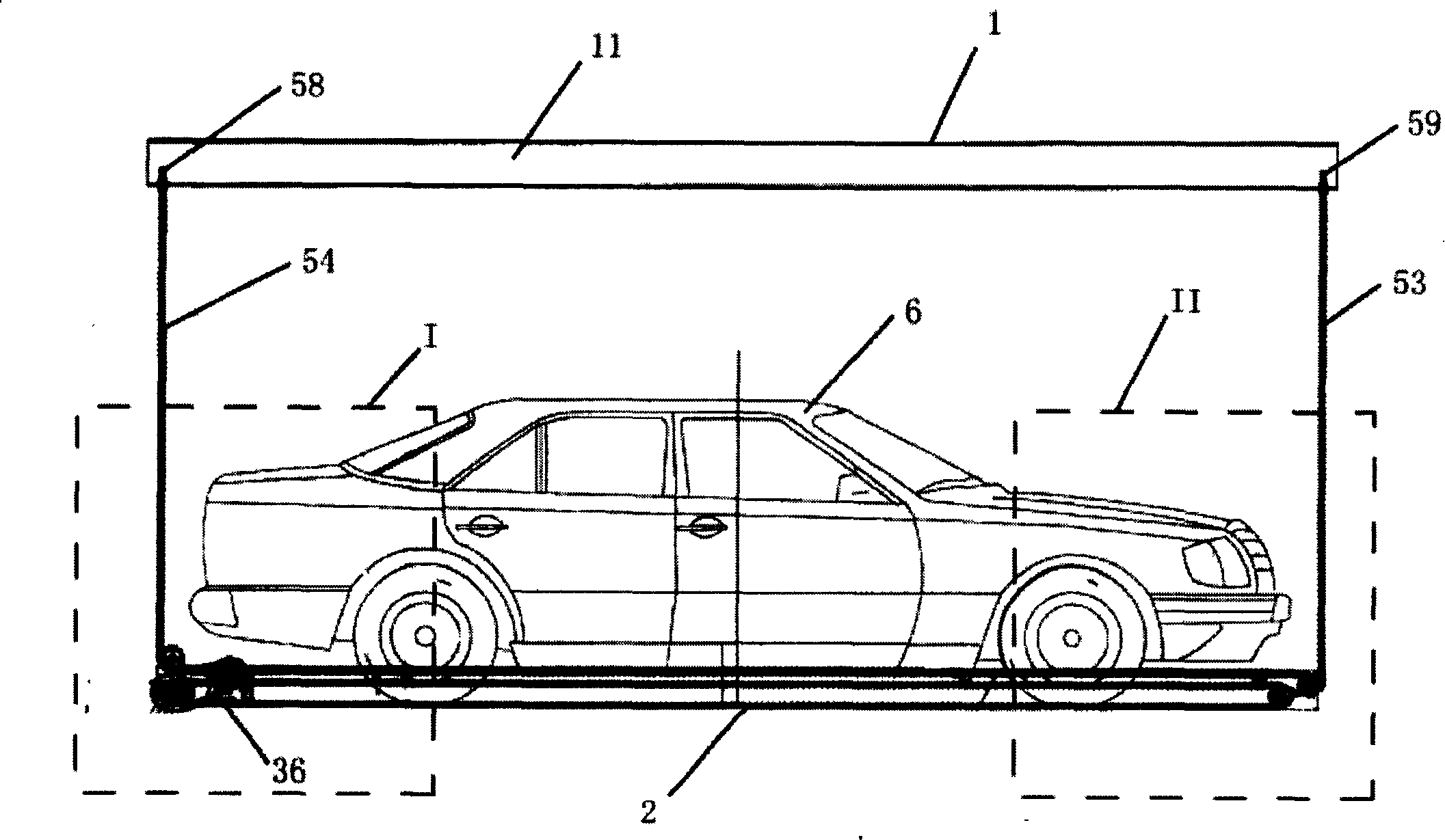

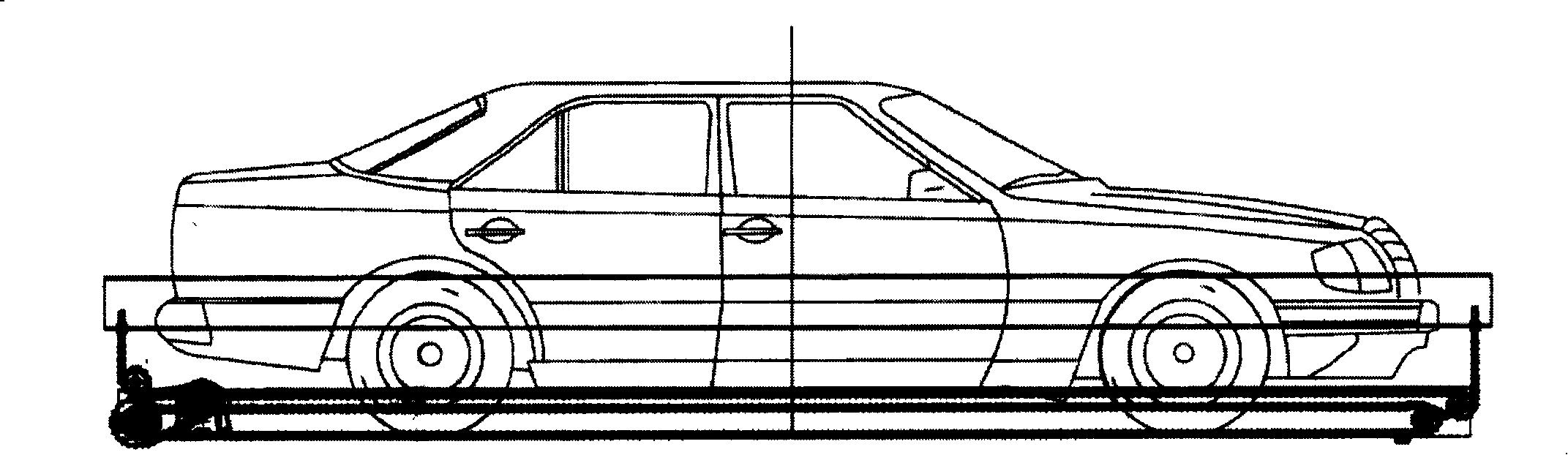

[0058] Each group of lifting mechanisms includes synchronous sprocket I 41, II 42, rear guide sprocket I 43, II 44, rear steering sprocket 45, front steering sprocket I 46, II 47, front guide sprocket I 48, II 49, front Idle sprocket I 51, II 52, front and rear suspension chains 53, 54, epicyclic chain I 55, II 56, four and a chain joint 57. The synchronous sprocket I 41, II 42 and the rear guide sprocket I 43, II 44 are keyed and fixed on the shaft end of the synchronous main shaft 34, and the rear guide sprocket I 43, II 44 is between the synchronous sprocket I 41, II 42 between. Rear steering sprocket wheel 45 axles are located on the vehicle-carrying platform 2 and have synchronous main shaft 34 one ends, and position is higher than synchronous sprocket wheel I 41, II 42 (referring to Figure 11 ).

[0059] Front steering sprocket I 46, II 47, front guide sprocket I 48, II 49, front idler sprocket I 51, II 52 axles are arranged at the other end of vehicle platform 2, and...

Embodiment 2

[0068] The present invention can also have the following changes: the rear guide wire rope wheels I, II replace the rear guide sprockets I 43, II44, the rear steering wire rope wheels replace the rear steering sprocket 45, the front steering wire rope wheels I, II replace the front steering sprocket I 46, II 47, the leading wire rope I, II replace the leading sprocket I 48, II 49, the front and rear suspension wire ropes replace the front and rear suspension chains 53, 54, four and one wire rope joints replace four and one chain joints 57 and the rest of the structure and Working principle is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com