Optical module and its alignment and assembly method

A technology of optical modules and assembly methods, applied in optics, optical components, installation, etc., can solve problems such as poor alignment accuracy and inability to improve the resolution of optical modules 1, and achieve the effect of improving alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

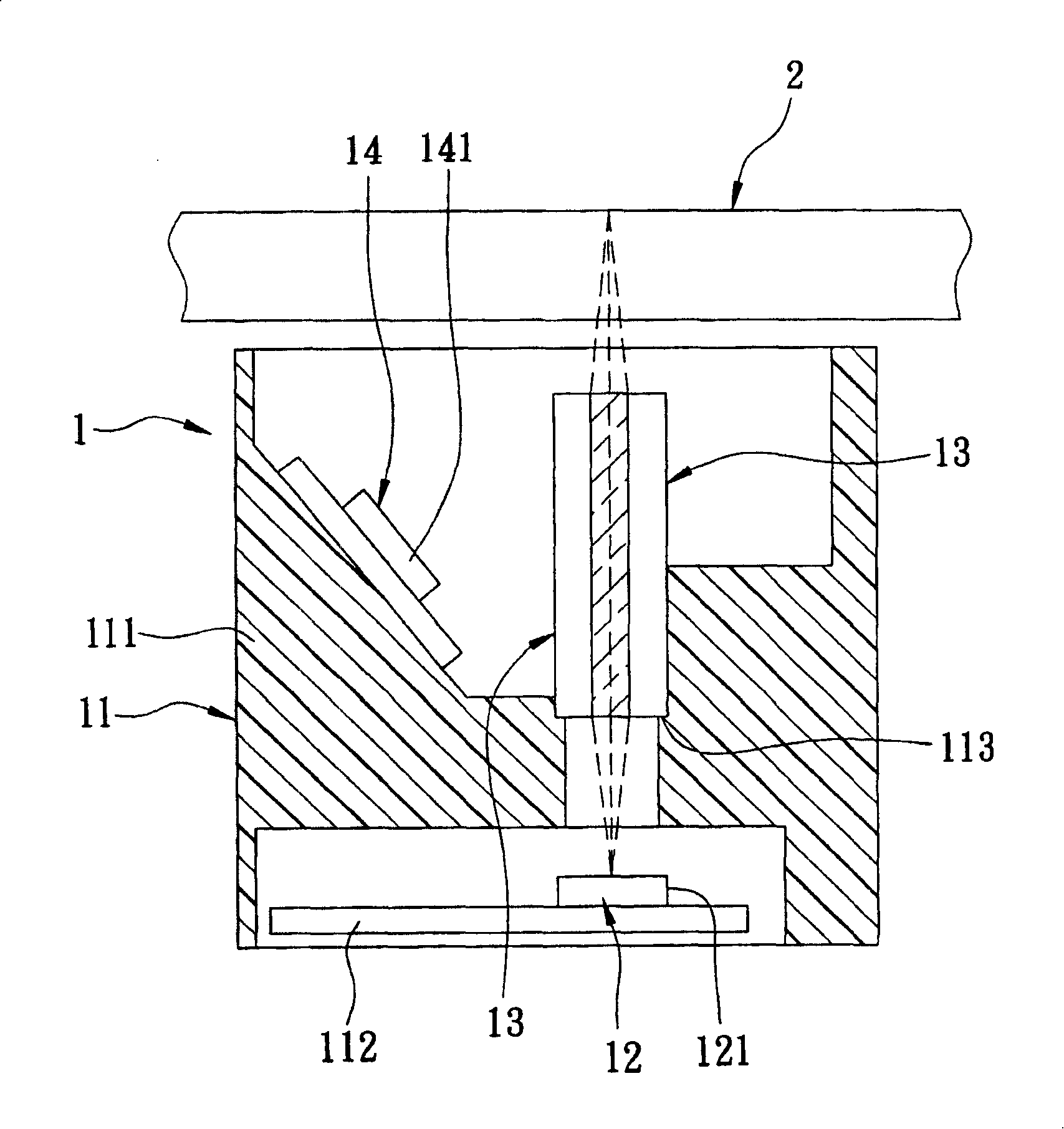

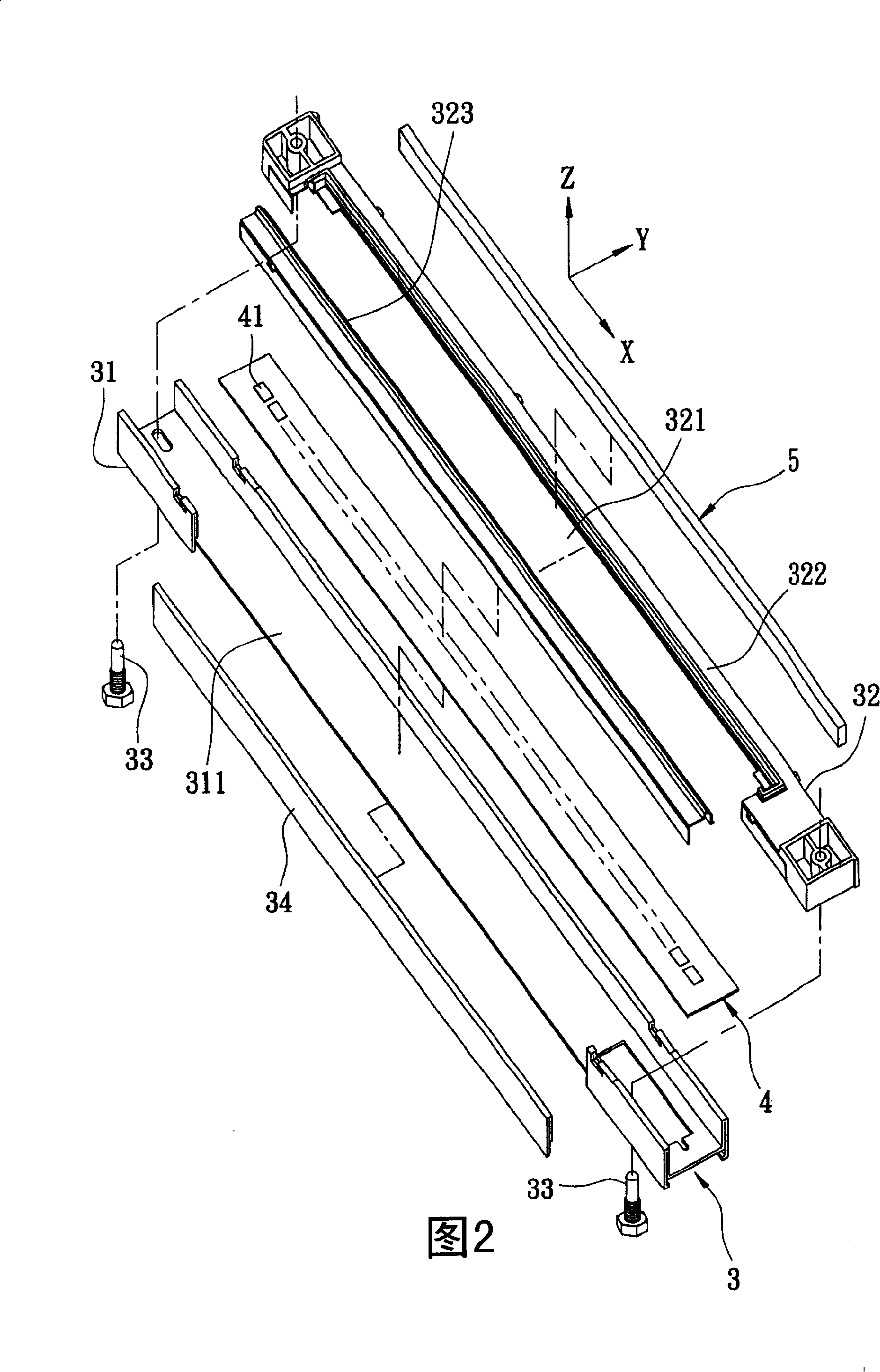

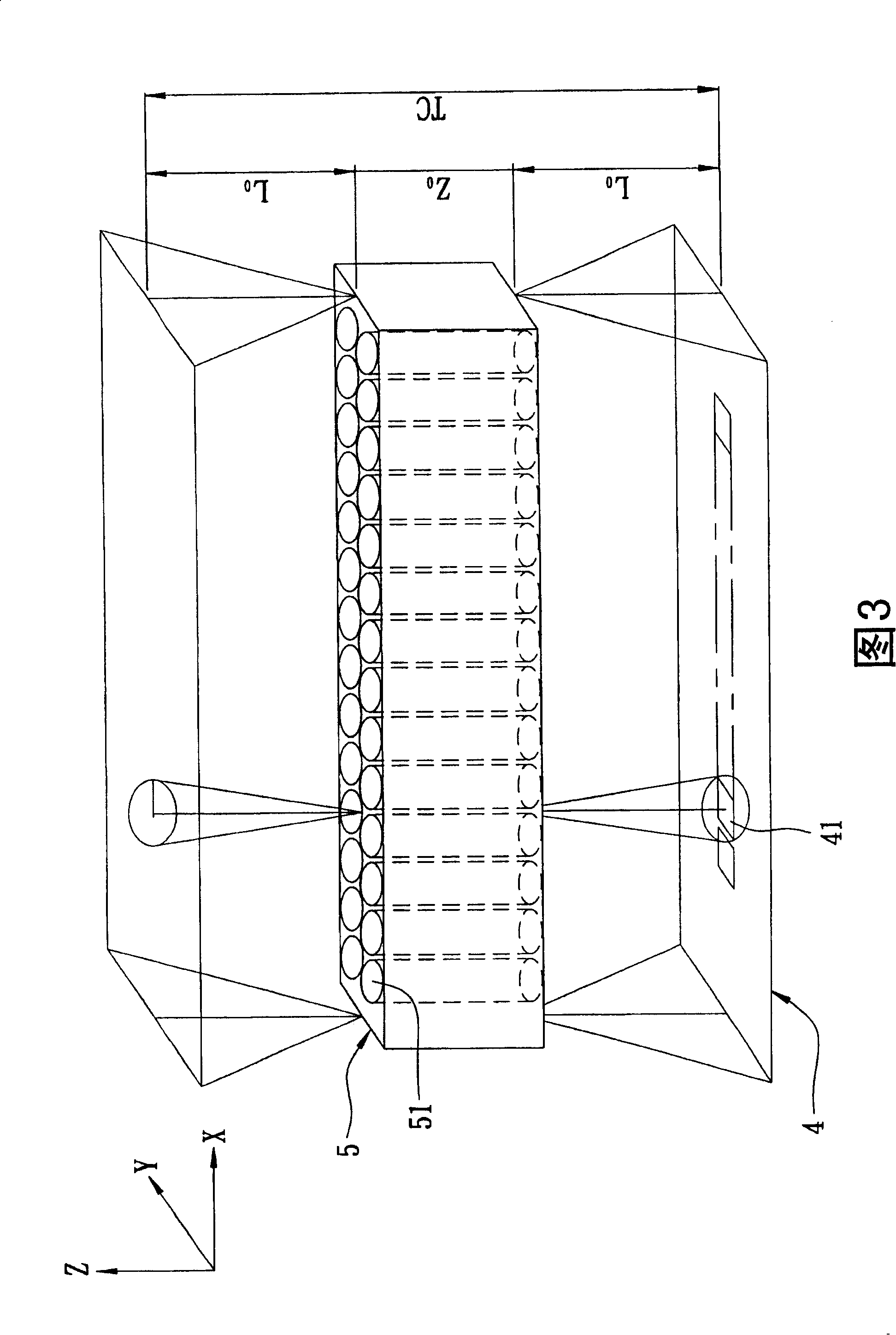

[0024] Referring to FIG. 2 and FIG. 3 , the preferred embodiment of the optical module of the present invention is an optical system applied to a light input device, and a light source is projected against a piece of glass 9 . The glass 9 has a top surface 91 capable of holding an object. The optical module includes: a housing unit 3 , a photosensitive unit 4 and a lens unit 5 .

[0025] The shell base unit 3 extends along the X-axis direction, and has a roughly U-shaped shell 31, a base 32 mounted on the shell 31, and two through the shell 31 and the base 32. Two positioning pieces 33 and a cover plate 34 at the end. The housing 31 has an opening 311 formed on one side and extending along the X-axis direction. The base 32 has a first mating part 322 and a second mating part 323 mated with each other and defining a slot 321. The second mating part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com