Power-driven system of aerial vehicle

A power-driven, aircraft technology, applied in the direction of aircraft, motor vehicles, aircraft parts, etc., can solve the problems that hinder the development and promotion of aircraft, heavy weight, increase in aircraft volume and weight, etc. The effect of efficiency, excellent controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

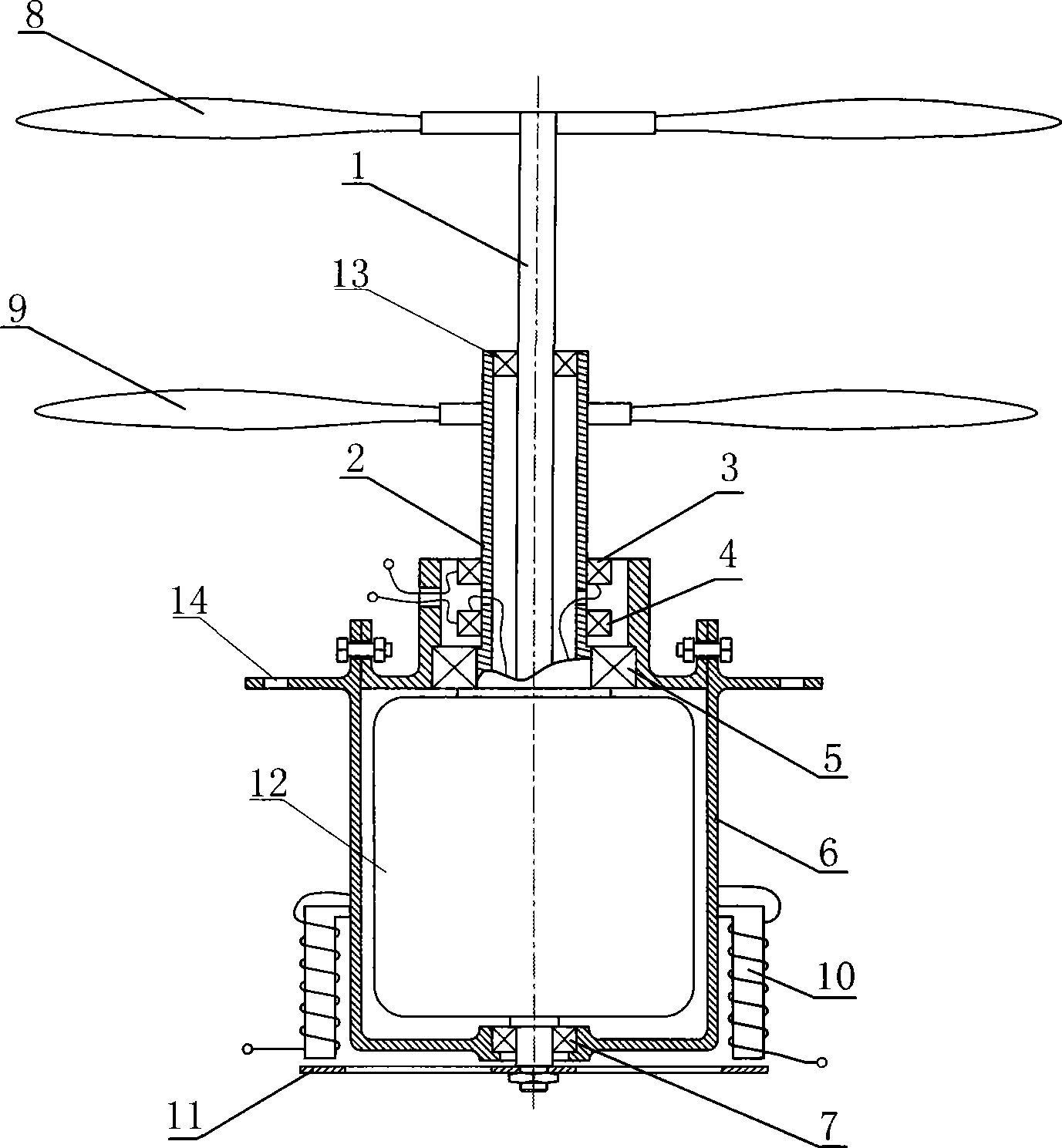

[0023] Embodiment 1 such as figure 1 As shown, in the power drive system of the aircraft, a storage battery is used as the power supply, and the motor is a special inner rotor brushed motor 12. The motor is vertically arranged in a bearing seat 6 through a bearing, and the stator 2 and the rotor 1 of the motor are all facing upwards. The propellers 9 and 8 are respectively installed in the direction of extension, the upper end of the stator and the rotor are installed coaxially with the propeller, and a turntable 11 is fixed after the lower end of the rotor 1 protrudes from the bearing seat. . One end of the motor is provided with a rotor bearing 7, and the other end of the motor is provided with a stator bearing 5. The propeller installed at one end of the rotor and the propeller installed on the stator are mutually rotating propellers, and the rotor bearing 7 and the stator bearing 5 are fixed on the bearing seat. ends. The bearing seat is provided with a fixed mounting ho...

Embodiment approach 2

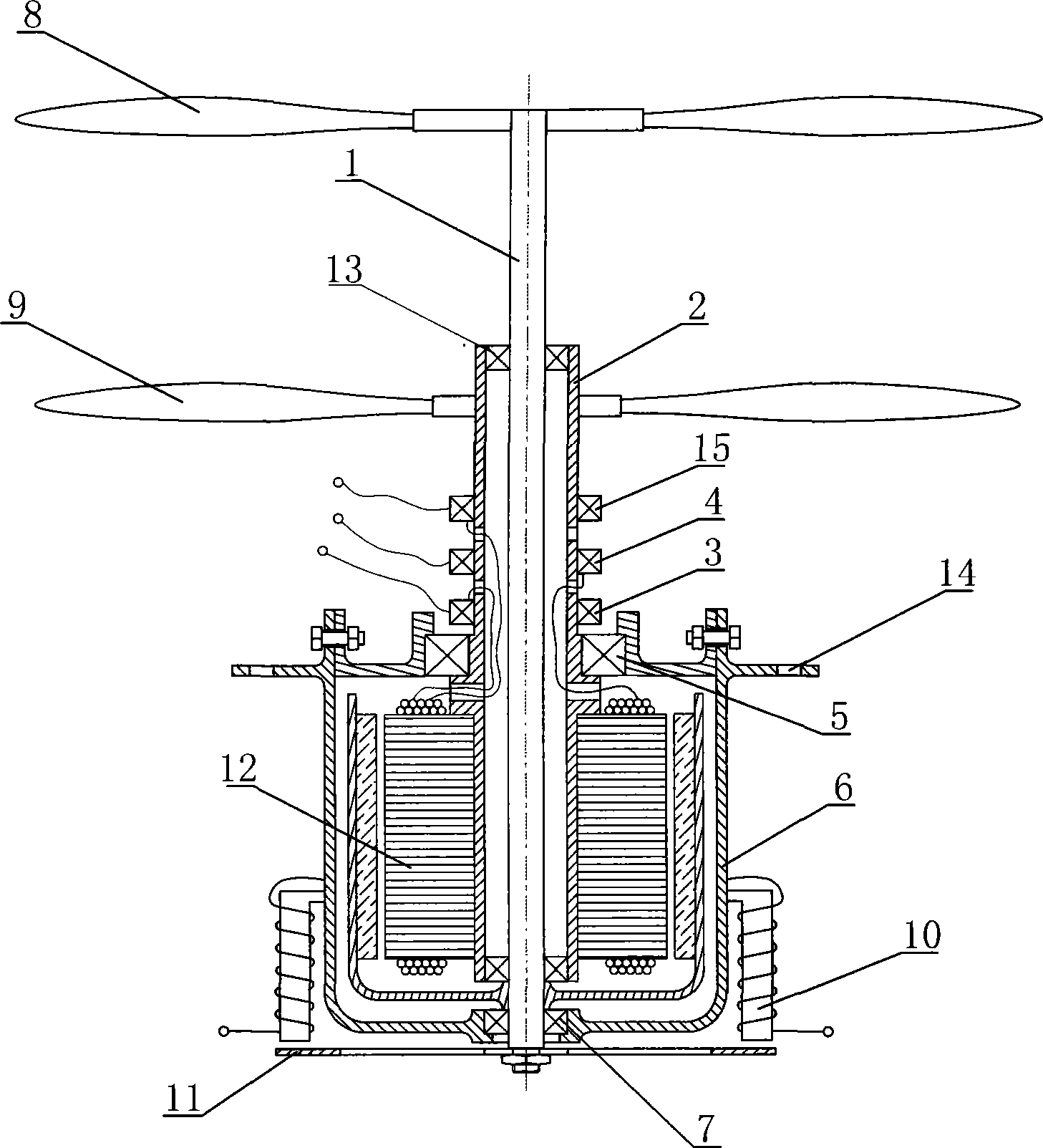

[0024] Embodiment 2 such as figure 2 As shown, in the power drive system of the aircraft, a storage battery is used as a power supply, and the motor is a special-made outer rotor brushless motor 12, and the outer rotor of the motor is a "mountain" font structure. The motor is vertically arranged in a bearing seat 6 through bearings, the stator 2 and rotor 1 of the motor extend upwards and are respectively installed with propellers 9 and 8, the upper end of the stator and the rotor are coaxially mounted on the propeller, and the lower end of the rotor 1 protrudes A rotating disk 11 is fixed behind the bearing seat, and an electromagnet 10 with a magnetic pole position close to the rotating disk is fixedly arranged outside the bearing seat. One end of the motor is provided with a rotor bearing 7, and the other end of the motor is provided with a stator bearing 5, and the propellers 9 and 8 are mutually rotating propellers, and the rotor bearing 7 and the stator bearing 5 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com