Display screen capable of self-checking trouble point and method thereof

A technology of fault points and display screens, applied to static indicators, measuring devices, instruments, etc., can solve problems such as incomplete display, low efficiency, and inability to find problems in time and accurately, achieve accurate detection results, solve detection problems, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

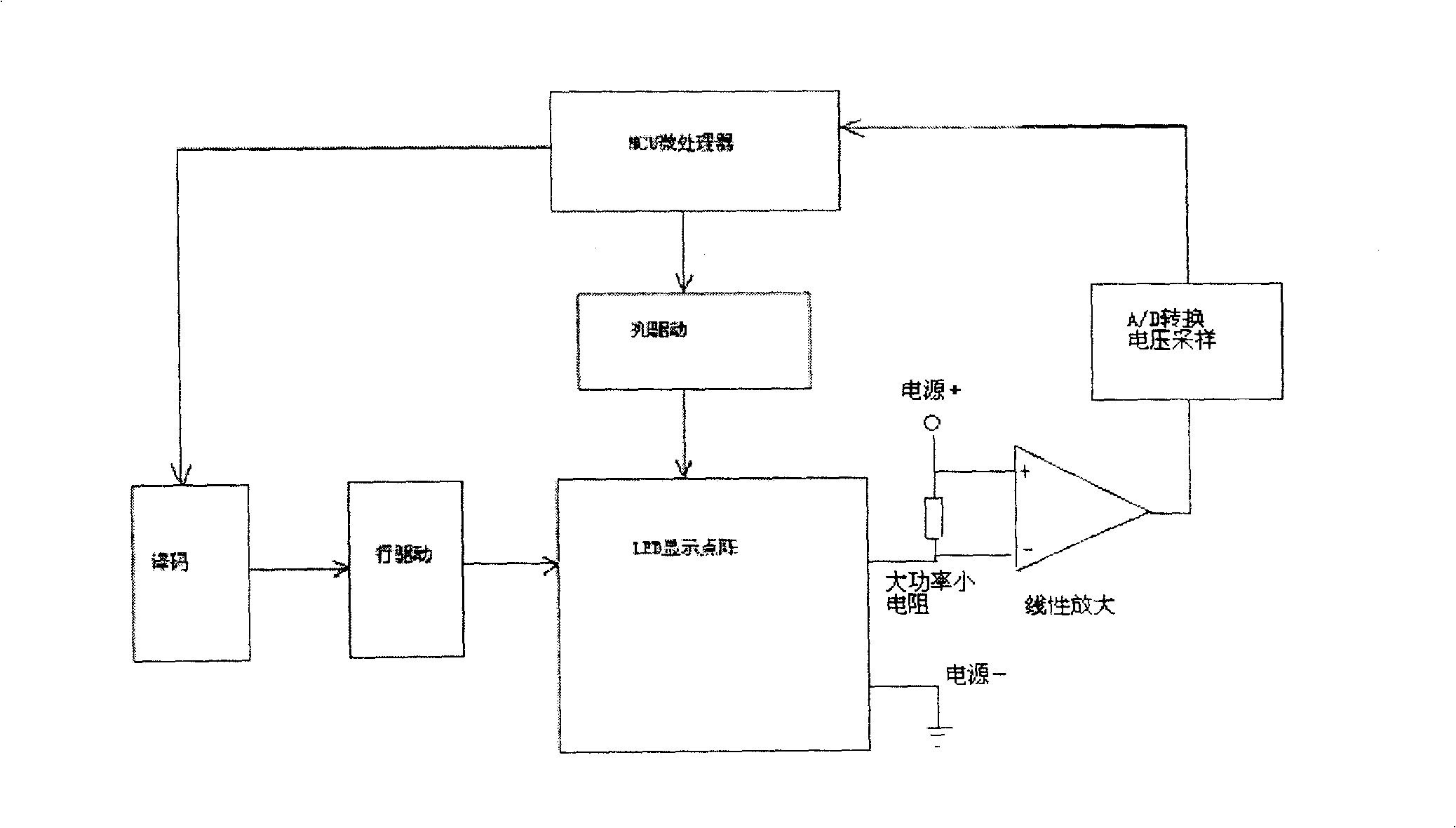

[0017] Such as figure 1 As shown, a display screen capable of self-checking fault points includes a microprocessor, the microprocessor is connected with a decoder, a row driver and a column driver, and is connected to the LED display screen through the row driver and the column driver, and The LED display is connected with a voltage sampling linear amplifier and an A / D converter, and the microprocessor converts the sampling voltage into a current after dividing the sampling voltage by a resistance value. The amplifier uses a linear amplifier.

[0018] The microprocessor is connected with a CPLD or FPGA control system, and a small-value resistor is connected in series before the overall power supply of the LED diode.

[0019] The microprocessor controls the CPLD or FPGA scanning method, controls the row and column drive through the decoding circuit, controls the LED light-emitting diodes to emit light and not light one by one, and samples the small-value resistor The voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com