Method of producing screw device, and screw device

A manufacturing method and thread technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of difficulty in ensuring the strength of the ball screw nut, and achieve the effects of dimensional stability, productivity improvement, and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

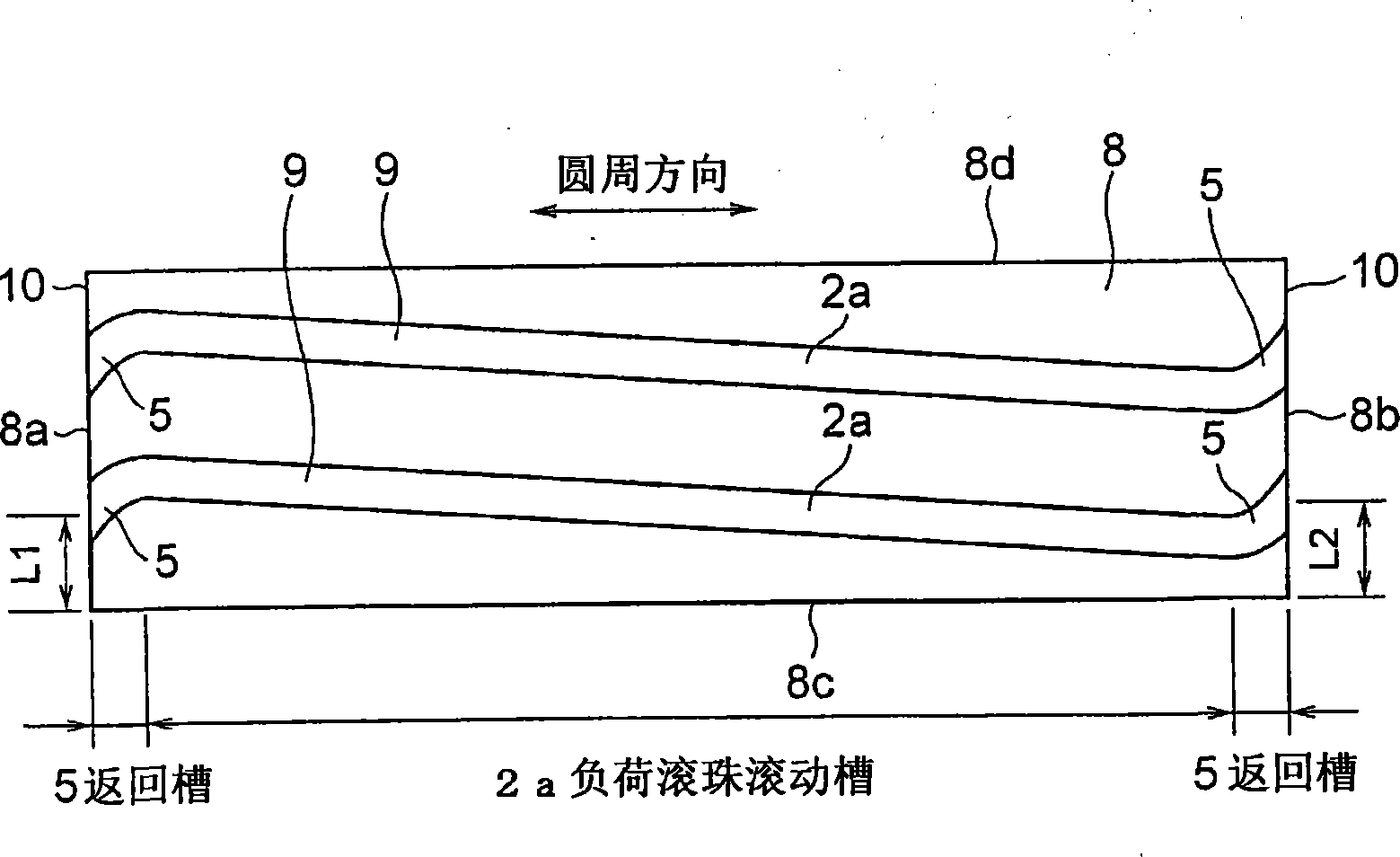

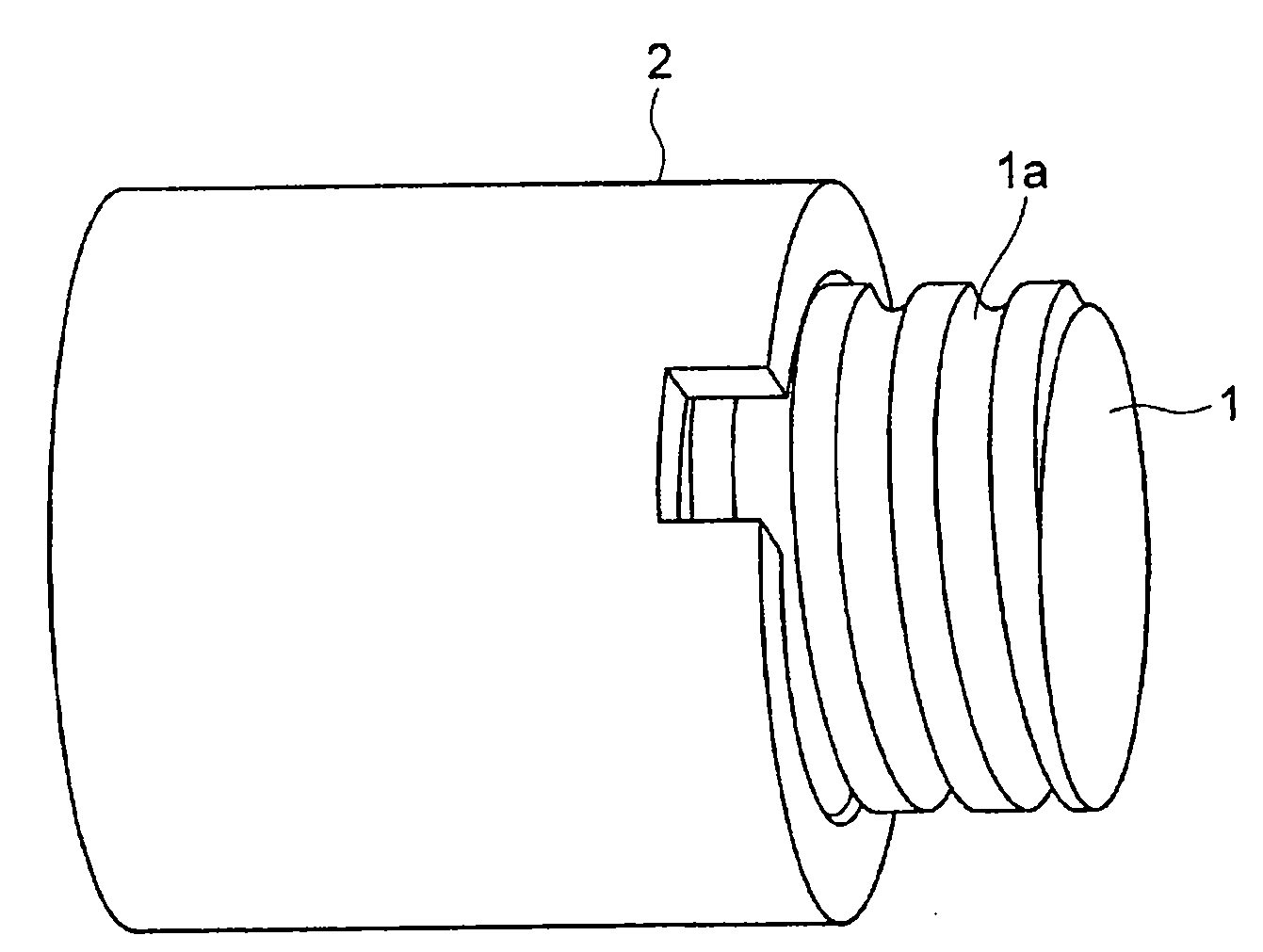

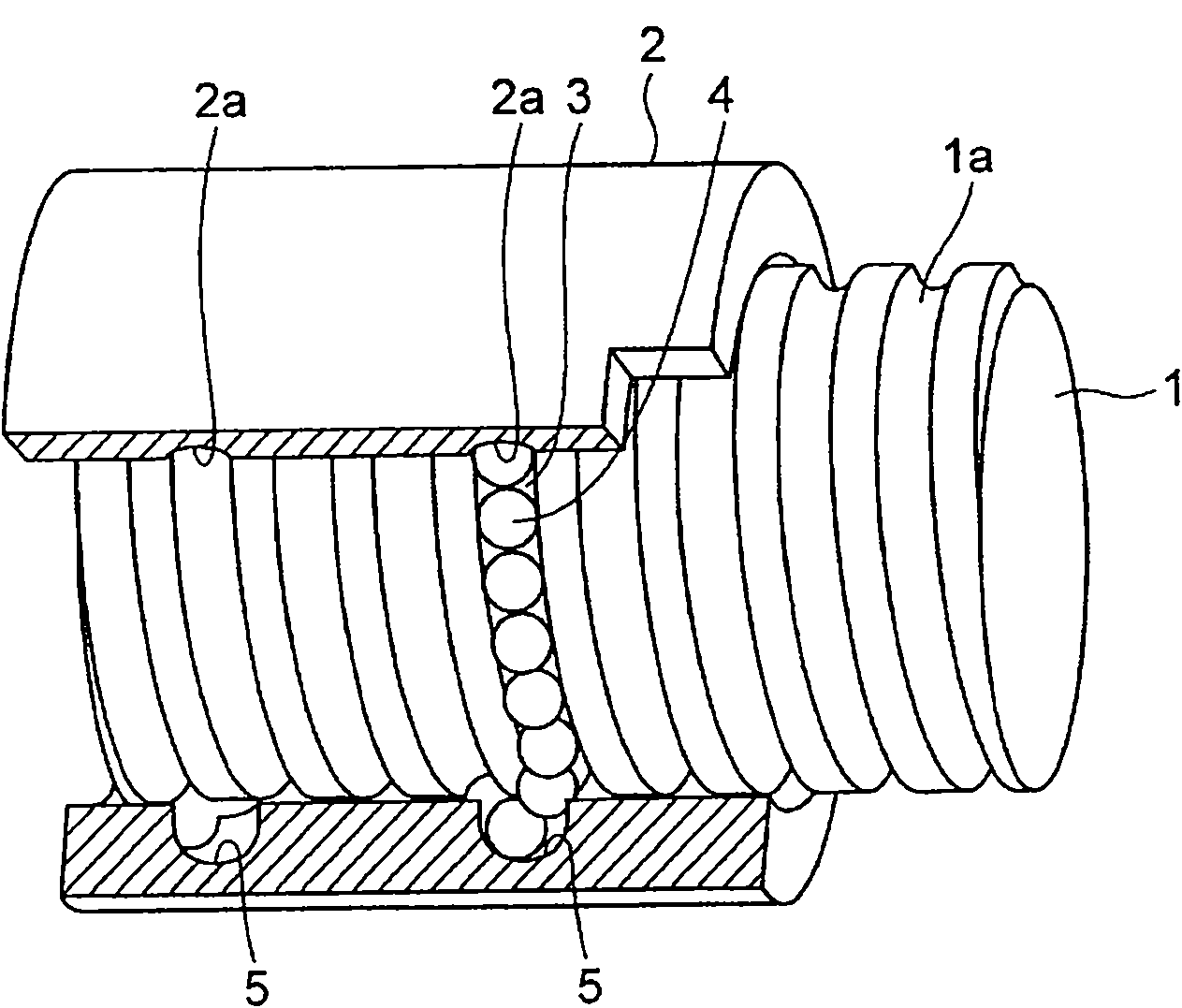

[0042] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. Fig. 1 and Fig. 2 show a screw device according to an embodiment of the present invention. Fig. 1 shows a perspective view of the screw device, and Fig. 2 also shows a perspective view of the screw device (including a partial cross section). The screw device aligns the rolling element rolling groove 1a of the threaded shaft 1 and the load rolling element rolling groove 2a of the nut 2 at the same position, and the resulting rolling element rolling path 3 incorporates balls 4 as rolling elements.

[0043] A ball rolling groove 1a is formed on the outer peripheral surface of the threaded shaft 1, and the ball rolling groove 1a has a predetermined pitch as a spiral rolling element rolling groove. The cross-sectional shape of the ball rolling groove 1a is formed into a so-called gothic arch groove shape by combining two arcs. The ball 4 and the ball rolling groove 1a contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com