Pipe laying machine device

A technology of pipe machine and casing, applied in the field of pipe laying machine device, can solve the problem of large-scale device and achieve the effect of simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

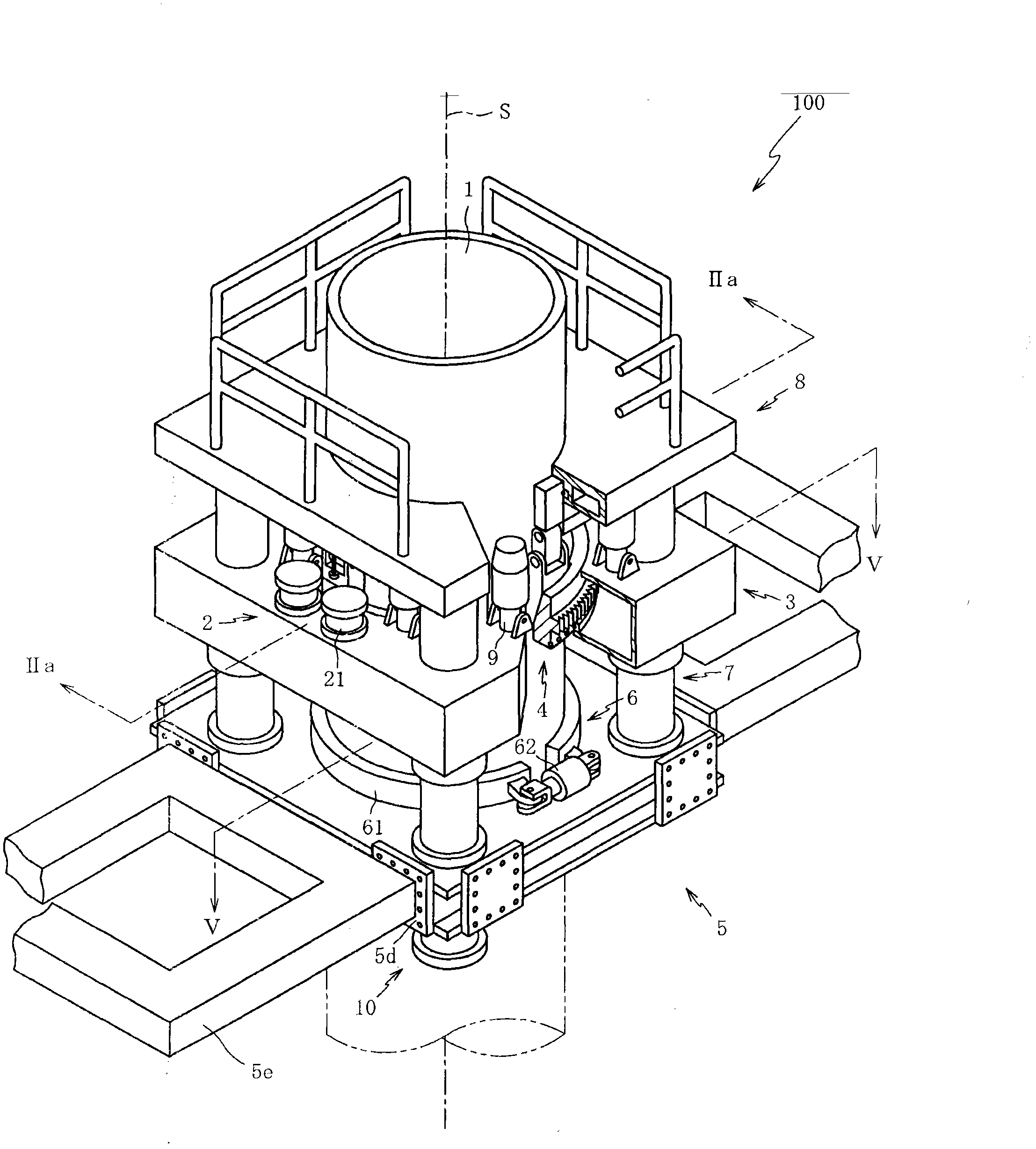

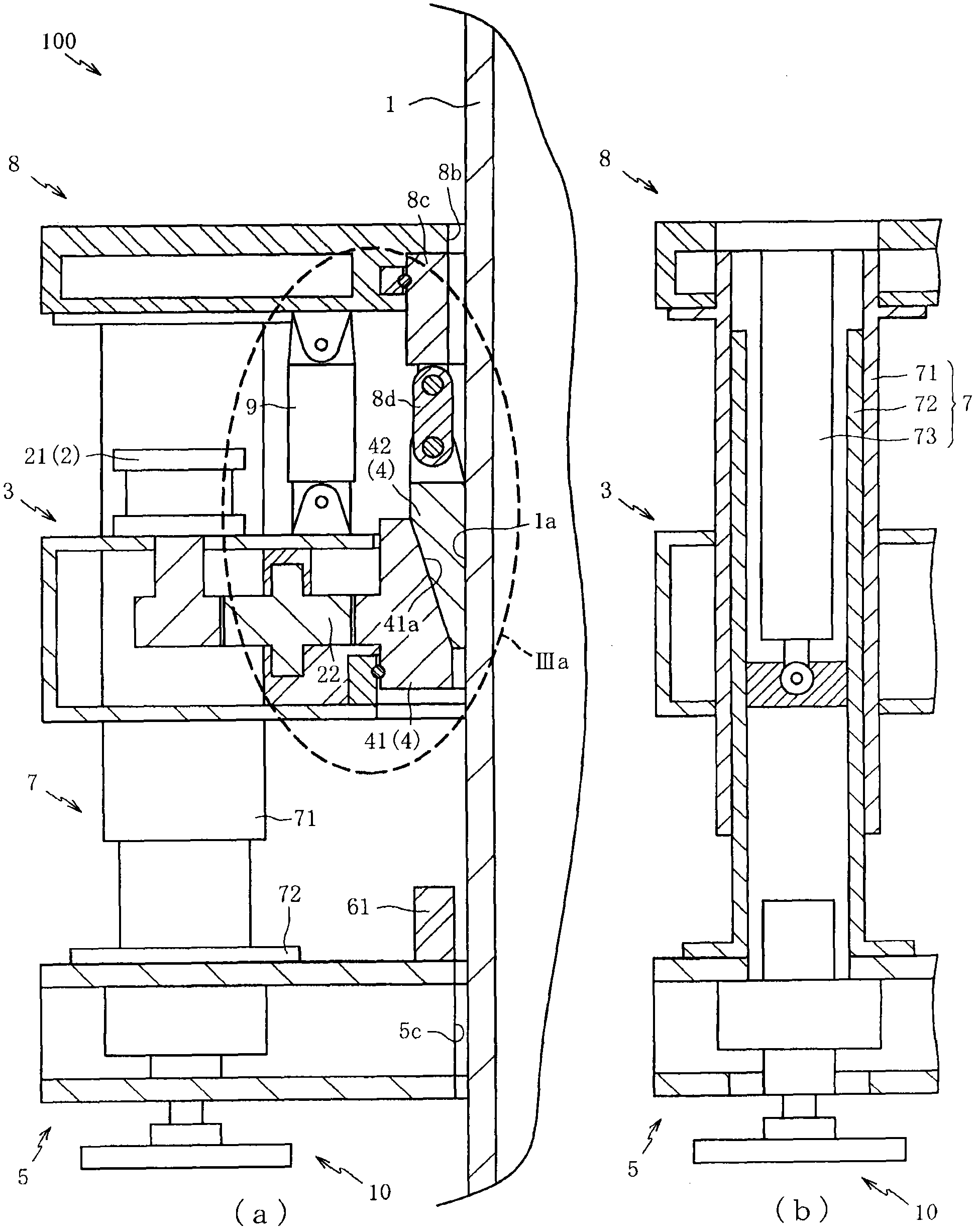

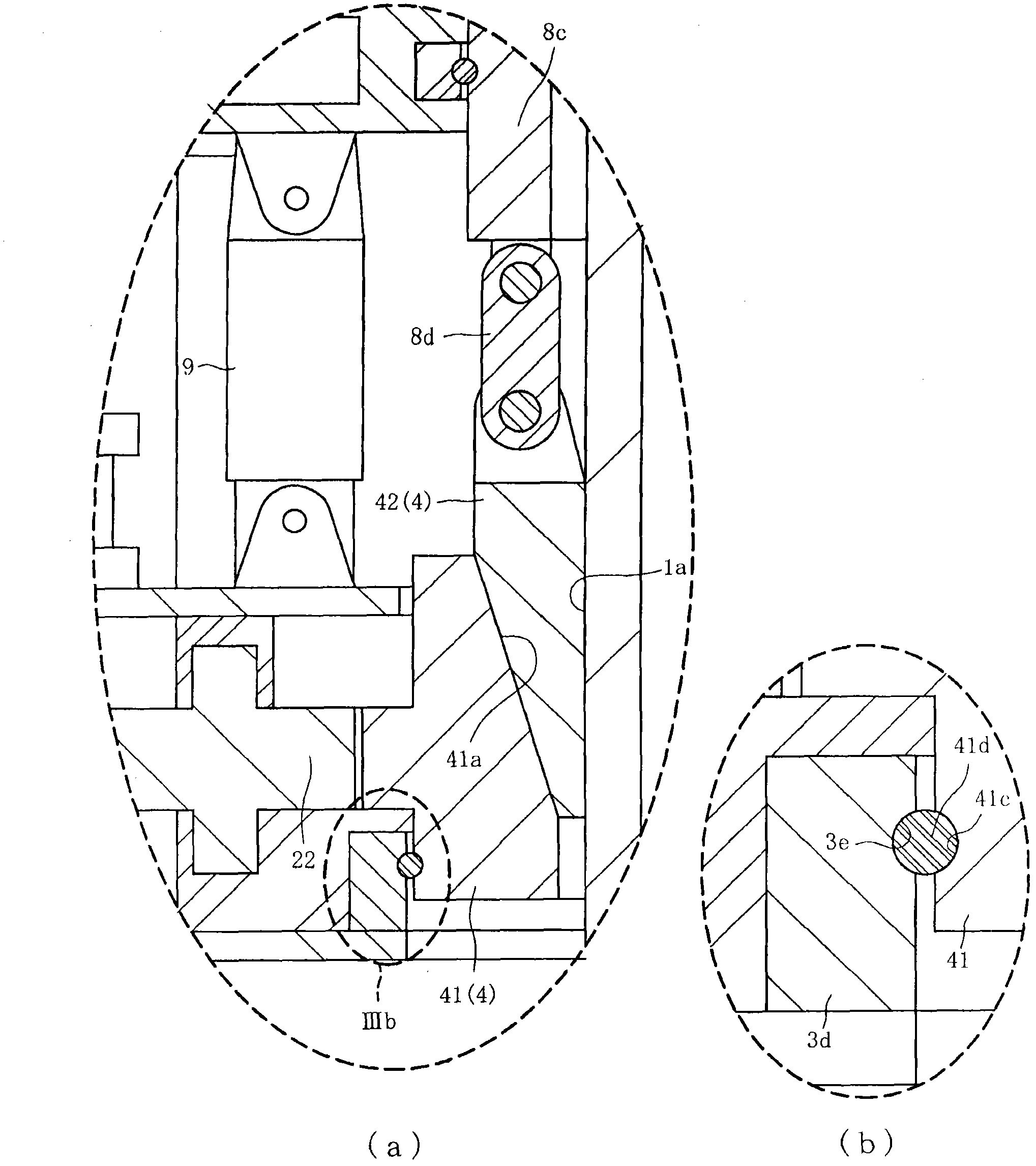

[0051] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 and figure 2 The configuration of the pipe layer device 100 will be described. figure 1 It is a perspective view of the pipe layer device 100 according to one embodiment of the present invention, and is shown in a state where the elevating member 3 and part of the upper frame member 8 are cut. figure 2 (a) is an enlarged representation figure 1 An enlarged cross-sectional view of a portion of the pipelayer device 100 taken along line IIa-IIa, figure 2 (b) is a sectional view of the thrust jack 7 .

[0052] The pipe layer device 100 is a device for pile construction in which a vertical vertical hole is excavated by pressing the casing 1 against the ground while rotating it. figure 1 As shown, it mainly has: a rotating drive mechanism 2, a lifting part 3, a main clamping part 4, a lower frame part 5, an auxiliary clamping part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com