Bowls and dish washing machine

A dish machine and dish machine technology, applied in the field of kitchen utensils, can solve problems such as poor water intake, inability to rotate the spray arm, and reduced water speed due to water pressure, so as to increase water consumption and motor power, ensure smooth water intake, The effect of increasing the number of nozzle holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

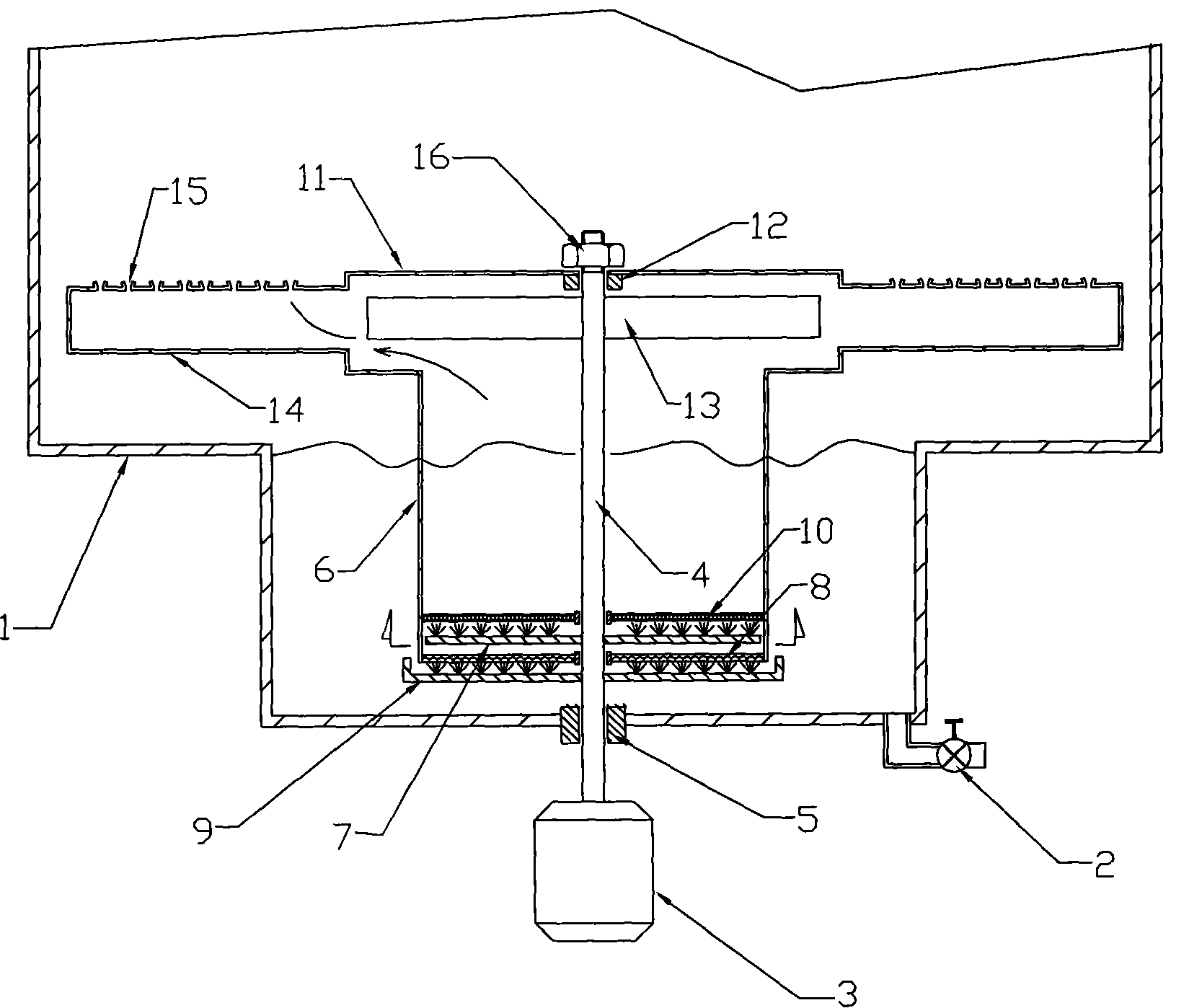

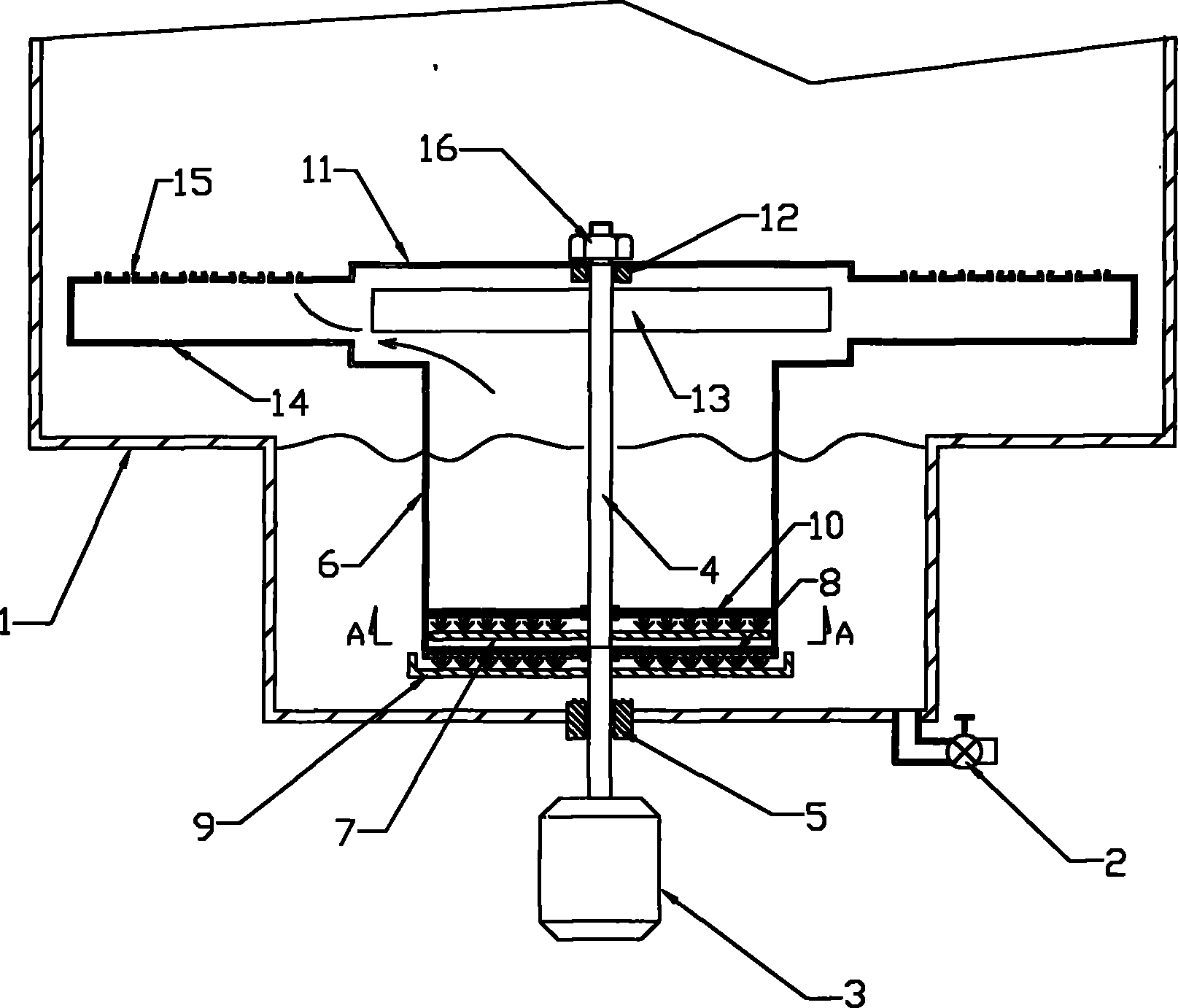

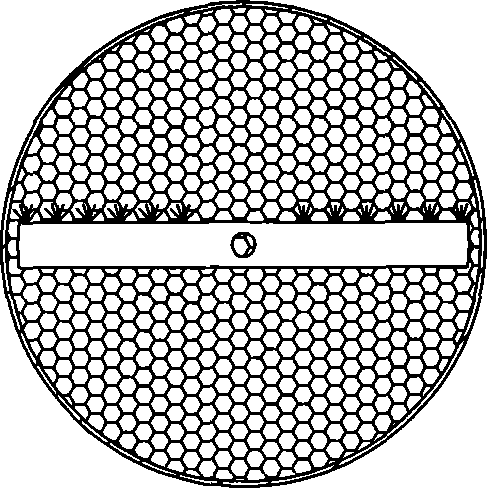

[0028] The dishwashing machine shown in Figures 1 to 3 includes a cabinet 1, the bottom of the cabinet 1 is provided with a drain port 2 and a drain valve, and the cabinet 1 is provided with a water-absorbing nozzle with four spray arms 14 facing downward at the bottom of the tube. Cylinder 6, the inner cavity of the spray arm with upward spray holes communicates with the water absorption cylinder, the mouth of the water absorption cylinder has filter screens 8, 10, and the bottom of the water absorption cylinder is supported by the bearing 12 and the bearing in the center of the filter screen to pass through the filter from the bottom of the cylinder mouth. The net passes through the vertical shaft 4 at the bottom of the tube. The vertical shaft 4 is supported on the chassis through the bearing 5 and driven to rotate by the motor 3. The upper part of the vertical shaft in the water suction tube is fixed with an impeller 13, and the top of the vertical shaft 4 is threaded. Nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com