PDP panel transfer vehicle

A turnover car and panel technology, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of easy damage and pollution panels, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

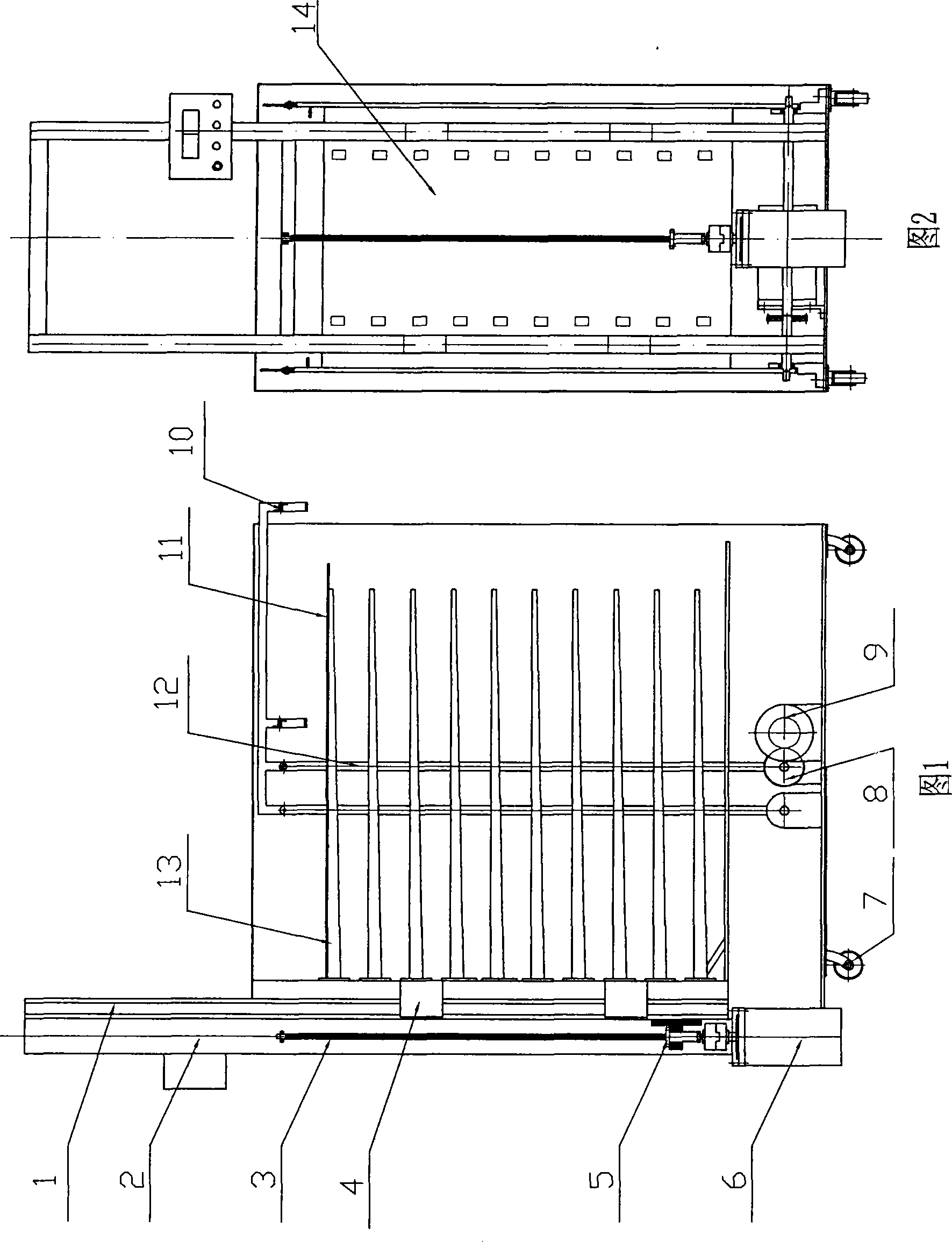

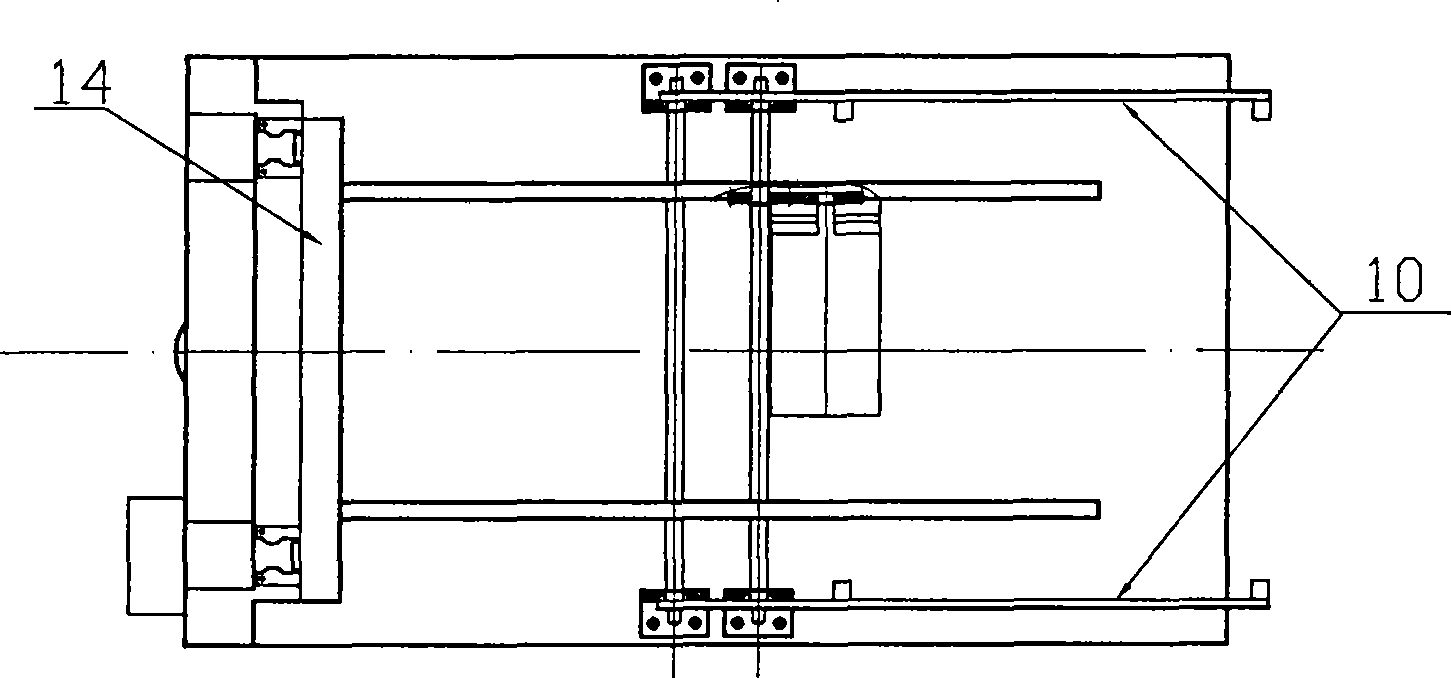

[0013] As shown in Figures 1, 2, and 3.

[0014] A PDP panel turnover car, which is mainly composed of linear guide rail 1, door-shaped square steel bracket 2, transmission screw 3, slider 4, nut 5, motor 6, casters 7, meshing gear set 8, motor 9, manipulator 10, Connecting rod 12, panel bracket 13 are formed, as shown in Figure 1, guide rail 1 is installed symmetrically on two straight sides of described door-shaped square steel support 2, as shown in Figure 2, is installed on each guide rail 1 Two interlocking sliders 4, wherein the lower two sliders 4 are connected to the screw nut 5 through a connecting piece, the screw nut 5 is installed on the screw 3, the screw 3 is installed in the square steel bracket 3 and Connected to the drive motor 6, the four interlocking sliders 4 installed on the two guide rails 1 are all connected to the panel bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com