Can coiler transmission mechanism of combing machine

A technology of transmission mechanism and sliver coiler, which is applied in the field of combing machines, and can solve problems such as the decline in finished product quality and the accidental drafting of combed sliver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

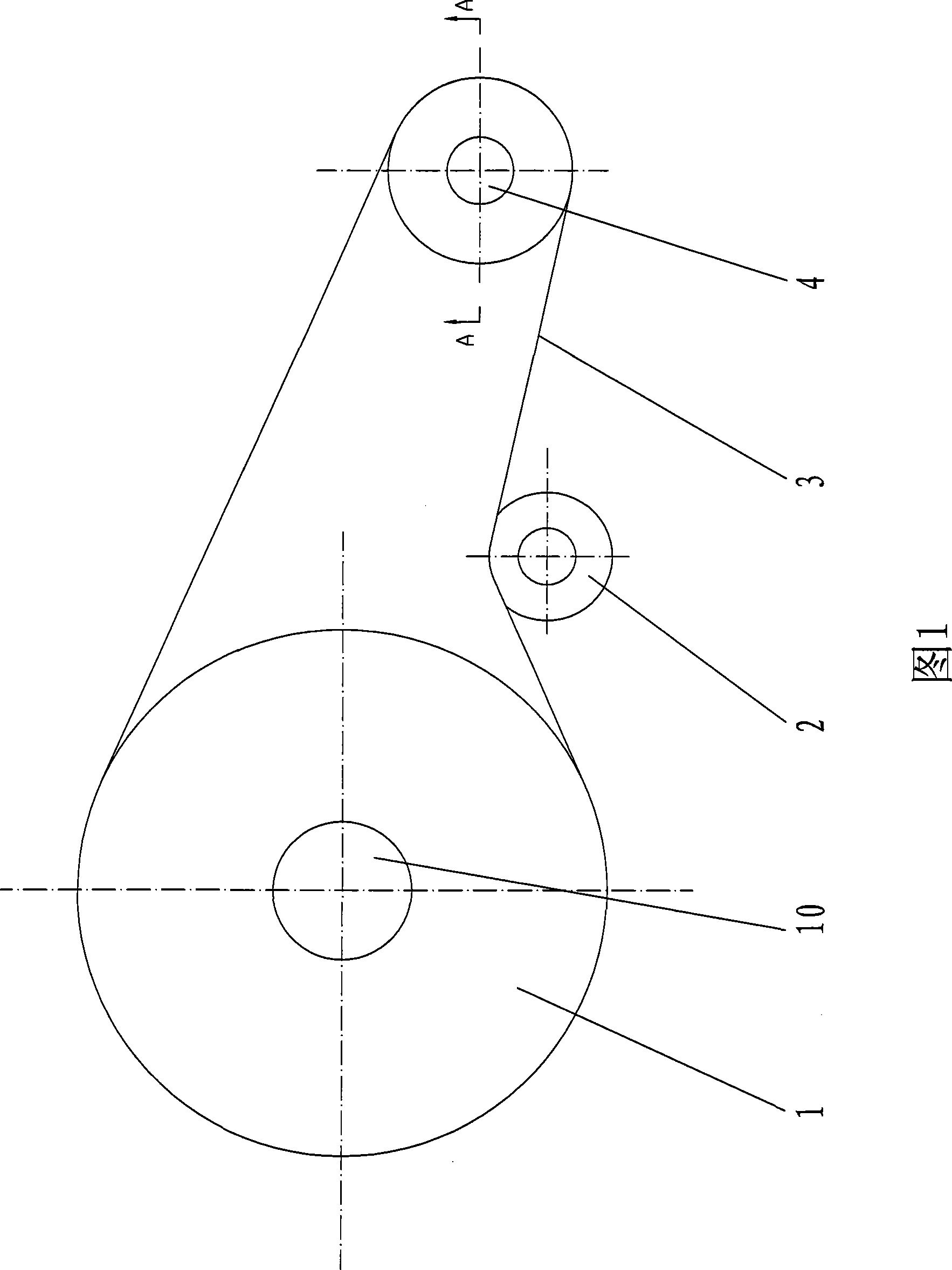

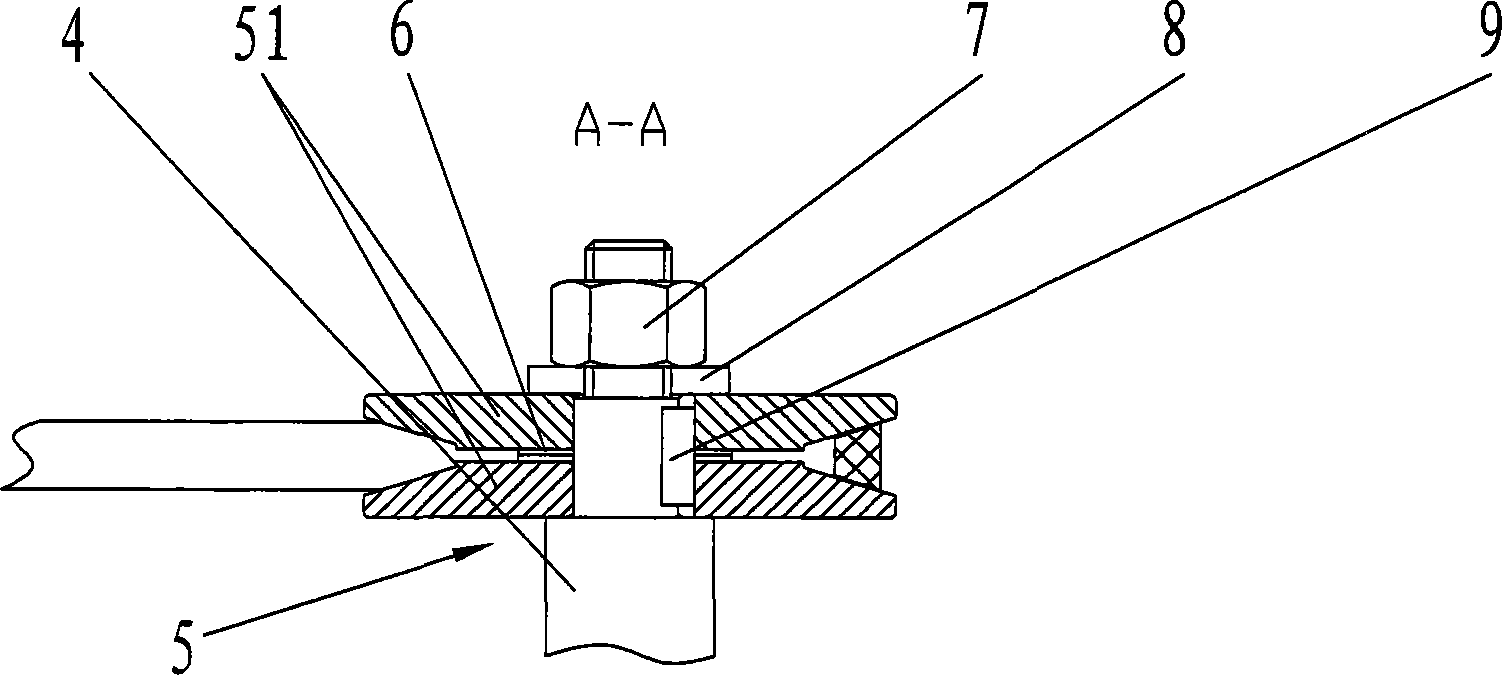

[0012] The present invention will be further described in detail below with reference to the drawings and specific embodiments: a coiler transmission mechanism of a combing machine includes a coiler V-belt 1 connected to the output shaft 10 of the coiler. The drive shaft V-belt 5 on the drive shaft 4 of the combing machine, the V-belt 3 used to connect the coiler V-belt 1 and the drive shaft V-belt 5, The tension wheel 2 of the V-belt 3 is tensioned.

[0013] In order to adjust the transmission ratio of the transmission mechanism and thereby adjust the rotation speed of the output shaft 10 of the coiler, the present invention makes some adjustments to the V-belt pulley 5 of the transmission shaft. The V-belt pulley 5 of the transmission shaft is composed of two wedge-shaped wheels 51 whose distance can be adjusted between each other. The two wedge-shaped wheels 51 are arranged symmetrically and the ends of the two smaller diameters are adjacent to each other. The V-belt 3 is clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com