Check valve

A check valve and valve seat technology, applied in valve details, control valves, valve devices, etc., can solve problems such as leakage, impact buffer effect, complex structure, etc., to ensure work safety, avoid impact, and eliminate water hammer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A preferred embodiment of the present invention will be specifically described below in conjunction with the accompanying drawings.

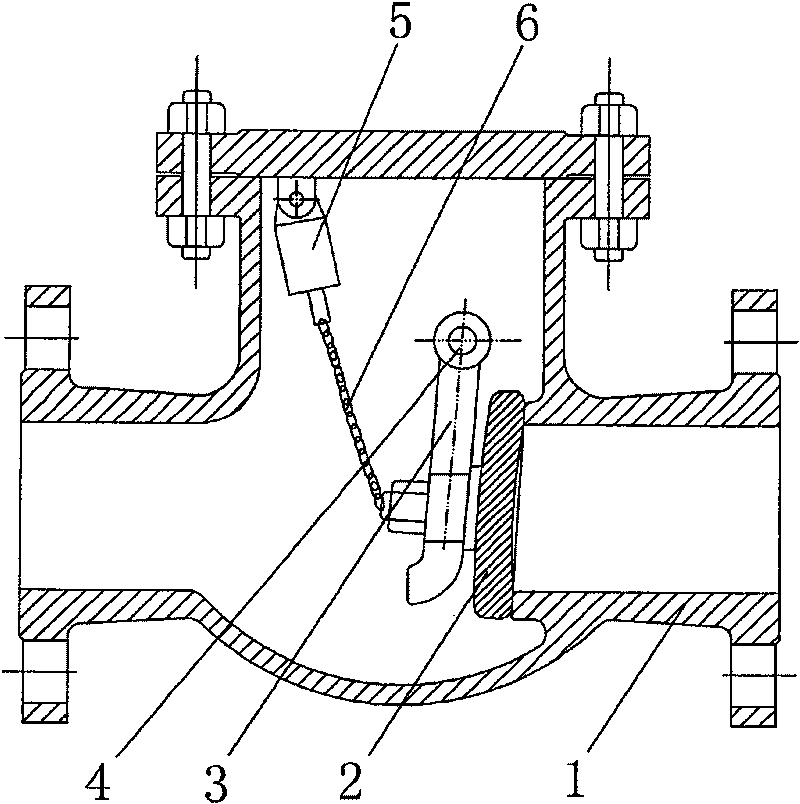

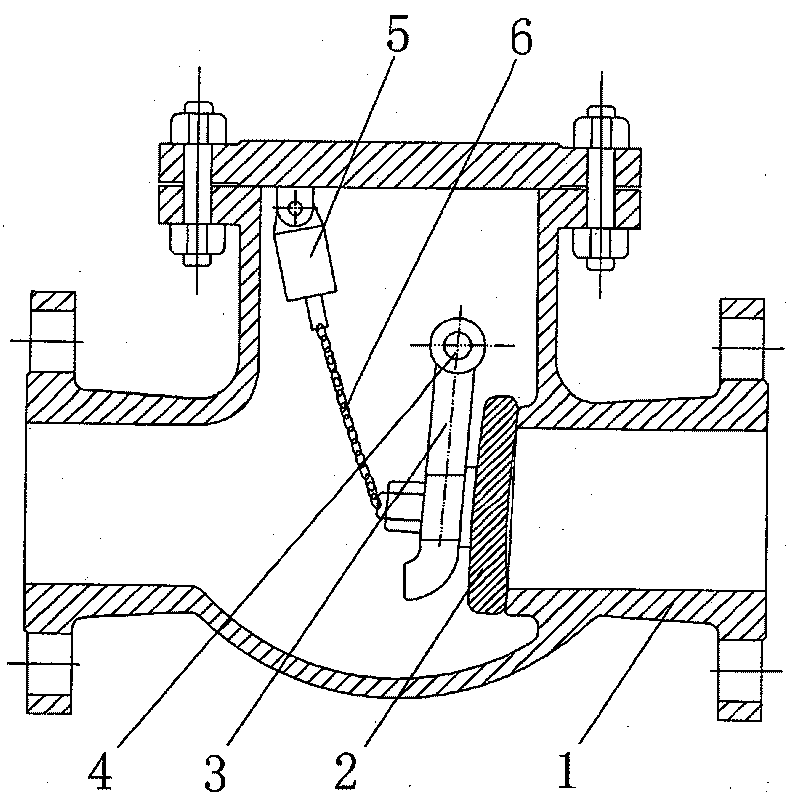

[0013] Such as figure 1 As shown, the check valve of the present invention includes a valve seat 1 and a valve disc 2, wherein the valve disc 2 rotates along the rotating shaft 4 through a rotating rod 3 fixedly connected thereto. Under the action of the valve, its sealing surface is closely matched with the sealing surface of the valve seat 1, thus closing the valve and preventing the medium from flowing backward. The present invention also includes a damper 5, the damper 5 is rotatably hingedly installed on the inner cavity wall of the valve seat 1, and its end is connected with the valve disc 2 through flexible parts such as chains or wire ropes 6 .

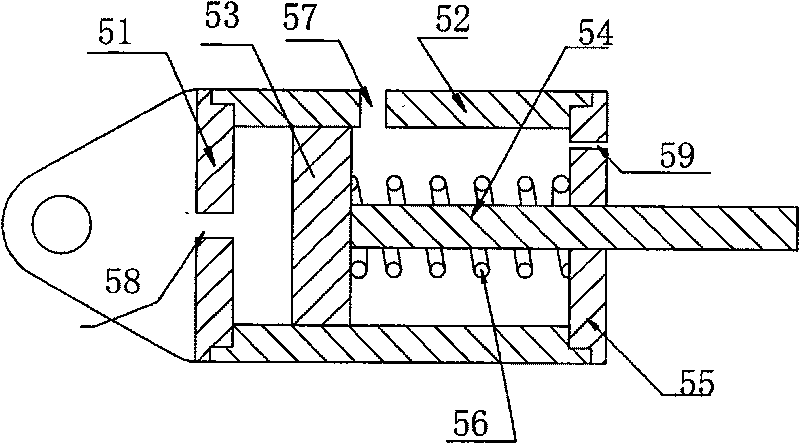

[0014] Such as figure 2 As shown, the damper 5 includes a rear cover 51 and a cylinder body 52. A piston 53 is arranged in the cylinder body 52, and a piston rod 54 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com