Electric kitchen appliance with bayonet joints for electric motor and transmission stage and method for mounting an electric kitchen appliance

A kitchen equipment and bayonet joint technology is applied in the field of installing electric kitchen equipment, especially electric single-use or universal kitchen machines, electric single-use or universal kitchen machines, electric motors and a transmission stage, which can solve the problems of expensive installation and manufacturing, etc. To simplify installation, improve product flexibility, and secure connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

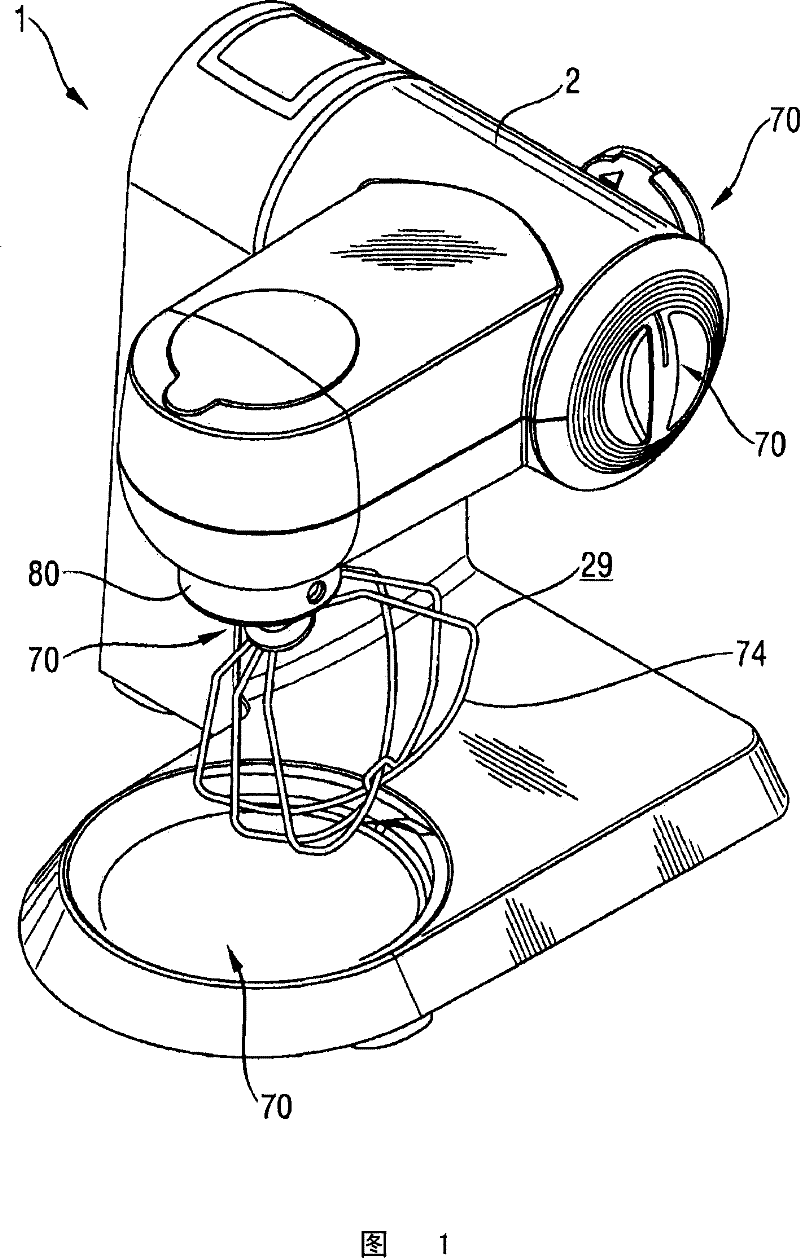

[0037] figure 1Shown is a perspective oblique view from the side of a kitchen appliance 1 according to the invention, which has a appliance housing 2 and four different sockets 70 for tools 29 which can be designed as whisks 74. Here, the motor 3 (see Figures 2 to 6 ) drives three of the four sockets 70.

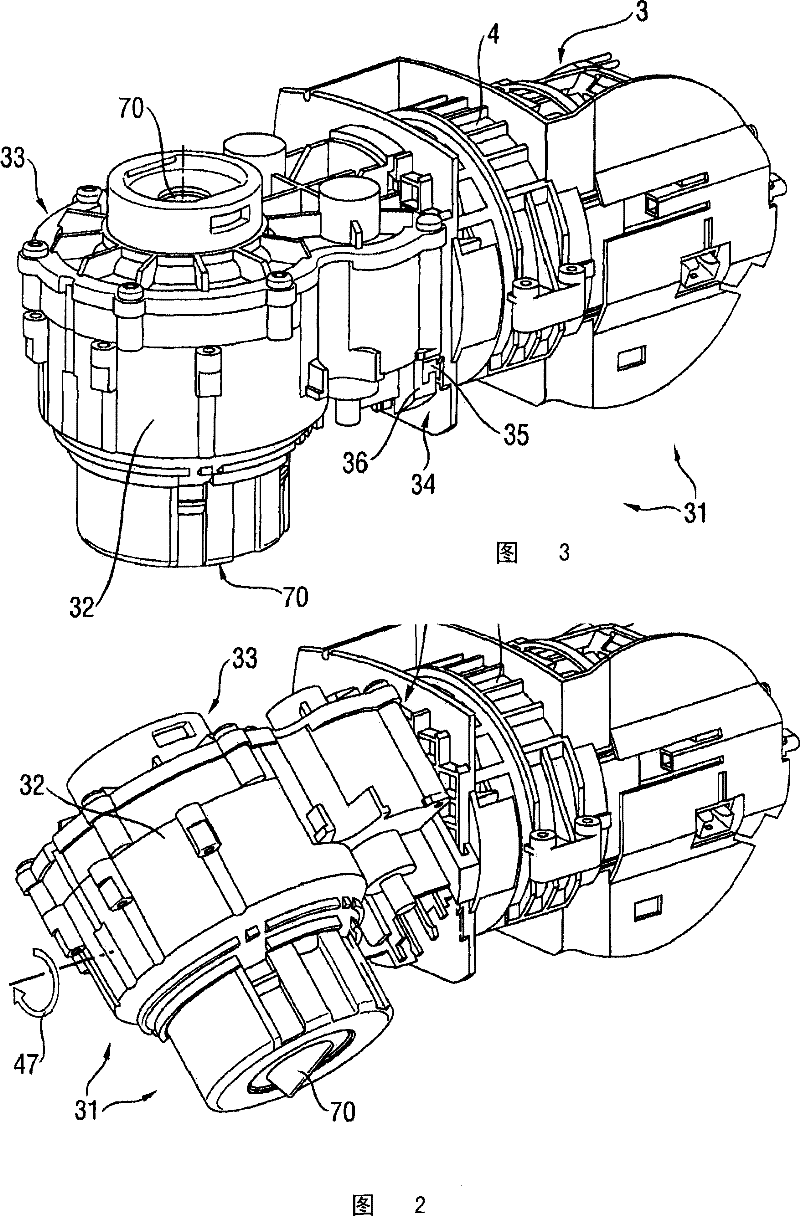

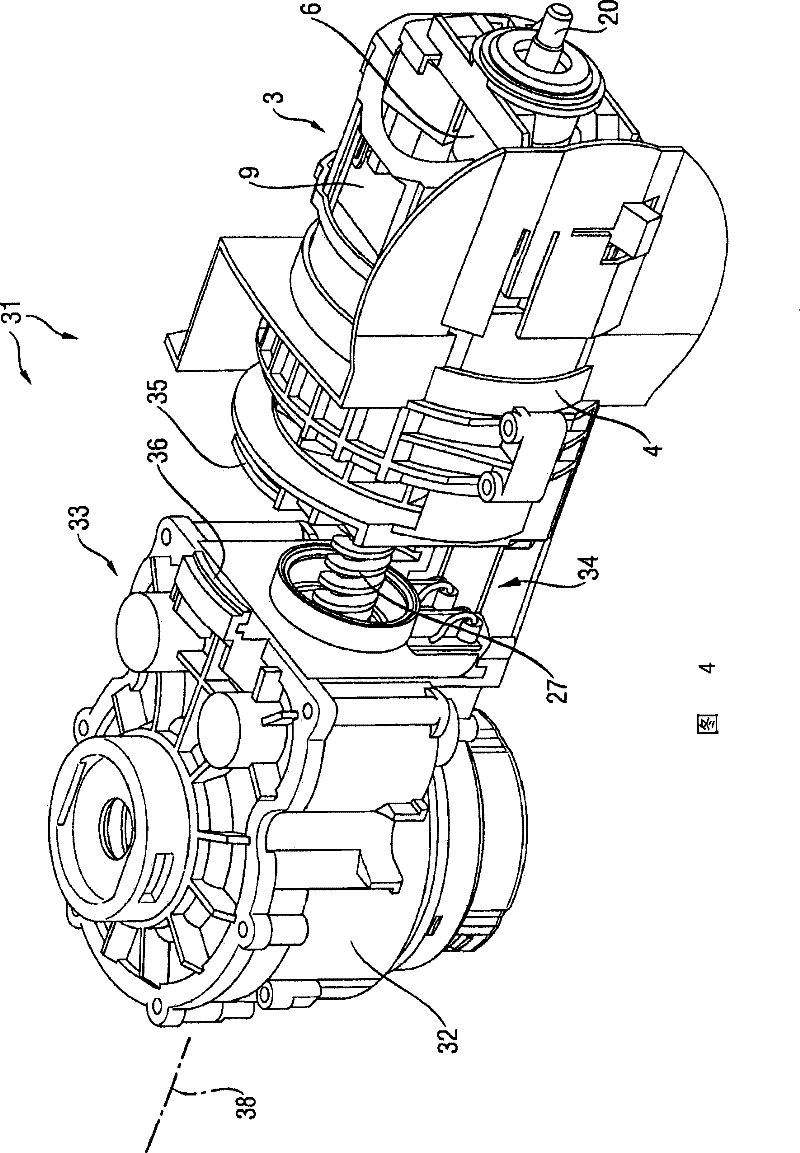

[0038] figure 2 Shows a perspective oblique view of the motor-transmission stage arrangement 31 of the kitchen appliance 1 according to the invention during pre-assembly, wherein the transmission stage 33 is connected to the electric motor 3 by connecting the transmission with a bayonet joint 34 The housing 32 and the motor housing 4 are connected to each other by sliding the transmission housing 32 onto the motor housing 4 , twisted at an angle, and securing it by rotation in the direction of rotation 47 . By means of the bayonet joint 34 , the transmission stage 33 can be connected easily but securely to the electric motor 3 by means of a swivel-extension movement. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com