Tea-leaf forming parching machine

A technology of frying and drying machine and tea leaves, which is applied in tea treatment before extraction, etc. It can solve the problems of tea leaves turning and throwing, and the shape of the guide leaf plate is not shaped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

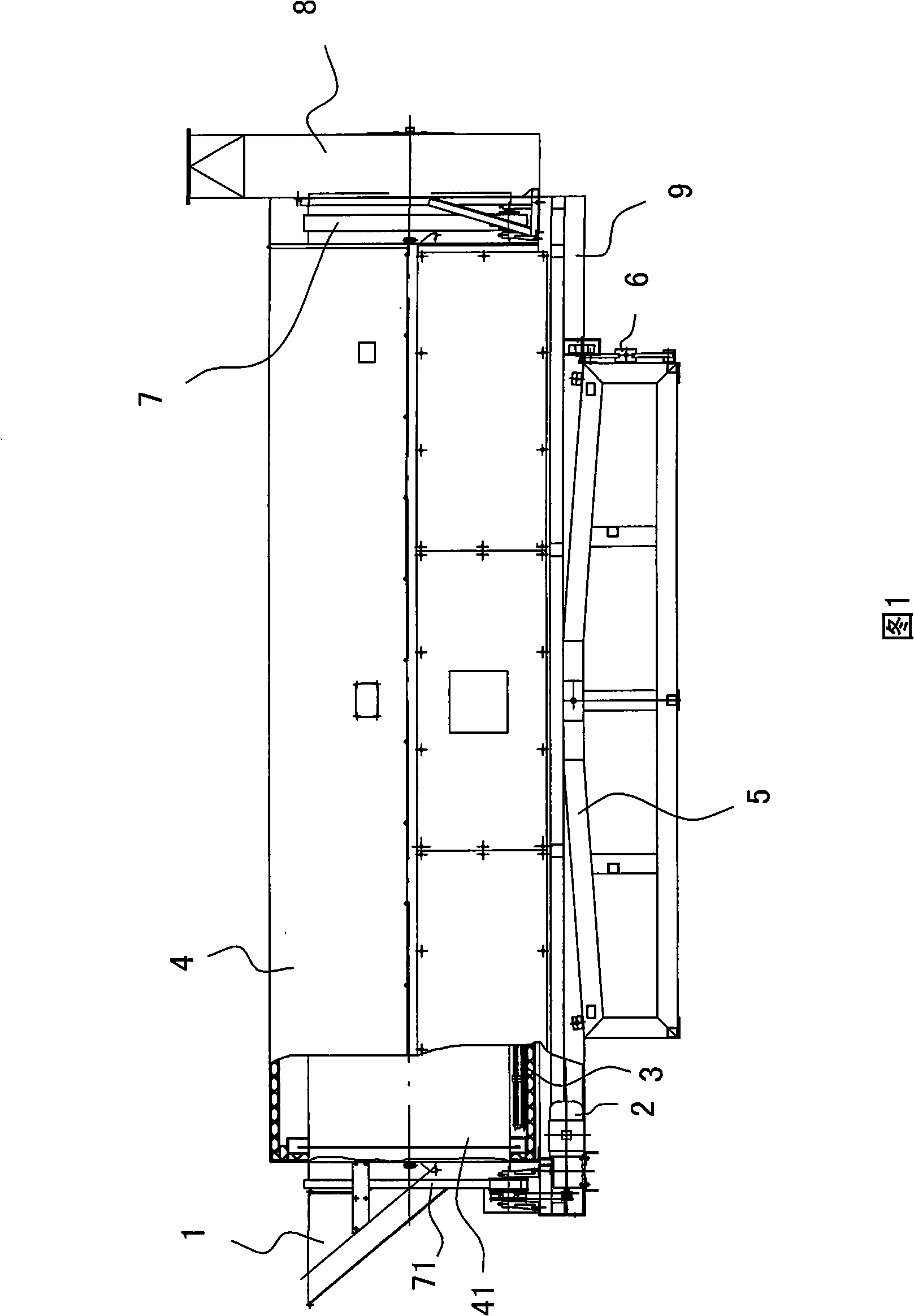

[0012] See Figure 1. The lower plane of the machine base 5 is firmly on the ground, and its upper plane forms a left-right long storage groove. There are two shaft holes in the upper middle of the front and rear side walls of the machine base 5, which are used to place the rotary shaft. 51. On the right side of support 5, be provided with angle adjustment mechanism 6, angle adjustment mechanism 6 can adopt manual or electric screw nut mechanism, also can adopt four-bar linkage. Angle adjustment mechanism 6 is used for adjusting the height of this end of frame 9, and the horizontal inclination angle of frame 9 can be adjusted by rotating the handle on the angle adjustment mechanism 6, that is, the axial inclination of cylinder 41, and the axial inclination of cylinder 41 can be Affect the walking time of tea leaves in the drum to achieve the purpose of controlling tea forming and frying time.

[0013] The outermost periphery of the frame 9 supported by the rotary shaft 51 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com