Double-edged eyelid forming agent

A forming agent, double eyelid technology, applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve problems such as difficulty in forming double eyelid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Sample No

[0048] 14

[0049] 27

[0050] Table 2

[0051] Sample No

[0052] 51

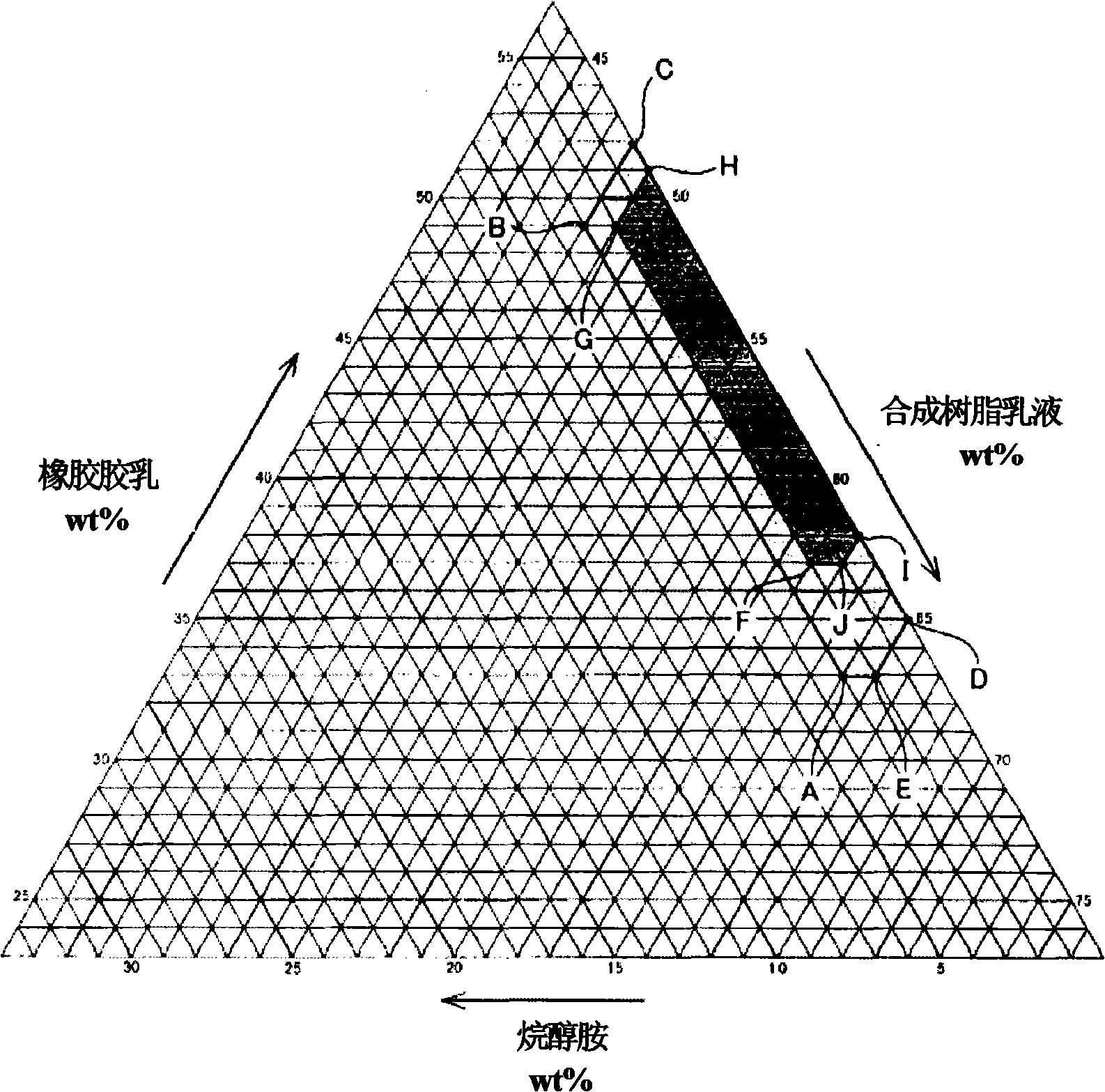

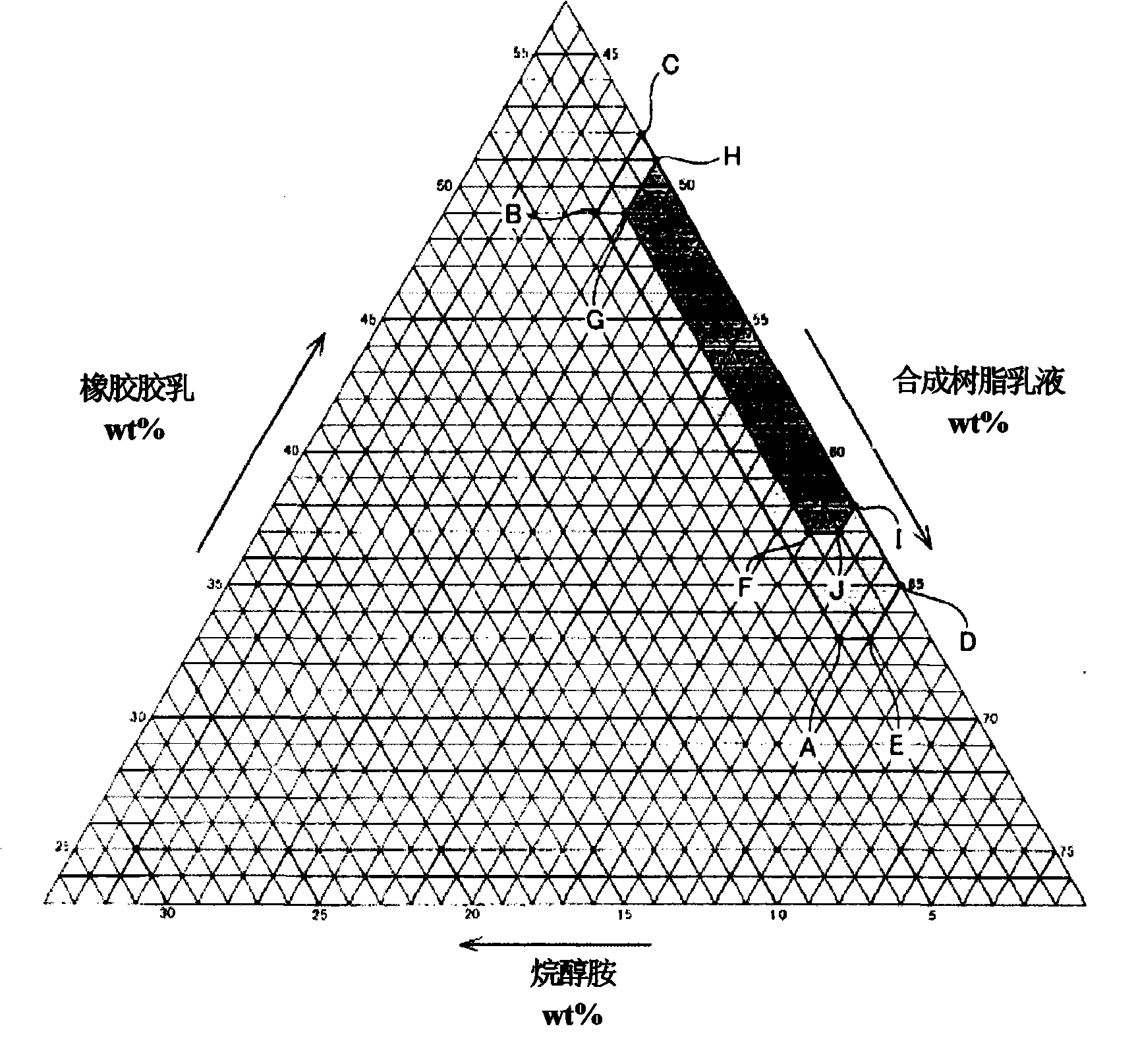

[0053] First, as shown in the sample numbers 1 to 6 in these tables, when the ratio of the synthetic resin emulsion is 47% by weight, that is, when the ratio of the synthetic resin emulsion is less than the line connecting point B and point C, the formed coating film The tensile strength is weak, and it is difficult to form double eyelids for people whose upper eyelid skin is too tight.

[0054]On the contrary, as shown in Sample Nos. 8 to 11, when the ratio of the synthetic resin emulsion is 48% by weight, that is, when the ratio of the synthetic resin emulsion is larger than the line connecting point B and point C, the tensile strength of the formed coating film Improvement, for people whose upper eyelid skin is too tight, double eyelids can also be formed.

[0055] In addition, as shown in sample numbers 1, 7, 13, 19, 25, 31, 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com