Construction method for filling and constructing earth stone dam by demixing dynamic compaction

A construction method, the technique of the dynamic compaction method, applied in the direction of dams, barrages, barrages, etc., can solve the problems of infeasibility, high density of earth and stone materials, and reduced settlement of the dam body, so as to reduce the volume of the dam body, increase the density, and The effect of subsidence reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

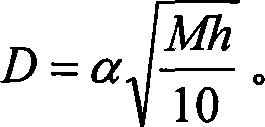

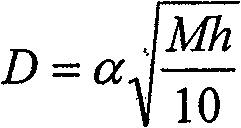

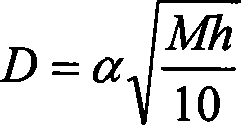

[0031] Example 1, the high-fill subgrade of Jingcheng Expressway, the subgrade soil is composed of weathered conglomerate and strongly weathered breccia, and the maximum particle size of soil-rock mixed filler is 260mm. First adopt layered rolling, the layered thickness is 50cm, but the degree of compaction can only reach 0.95. Afterwards, the subgrade is rammed by the dynamic tamping method. The layered thickness of the subgrade is 5m. The construction parameters of the dynamic tamping method are: the weight of the tamping hammer is 107kN, the diameter of the tamping hammer is 2.25m, the drop distance of the tamping hammer is 10m, and each point is 10 hits. The ratio decreased from 0.53 to 0.41, the porosity decreased from 0.35 to 0.29, and the degree of compaction increased from 0.95 to 1.06.

[0032] The implementation steps are as follows:

[0033] (1) Control the filling thickness of each layer of soil and rock to 5m; (2) Adopt high-energy ramming power preloading to inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| void ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com