Automatic gear shifting system of paper chipper

A paper shredder, automatic technology, applied in the direction of the control system, single-phase induction motor starter, motor generator/starter, etc., can solve the problems of lack, different motor output power, etc., and achieve the goal of improving compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

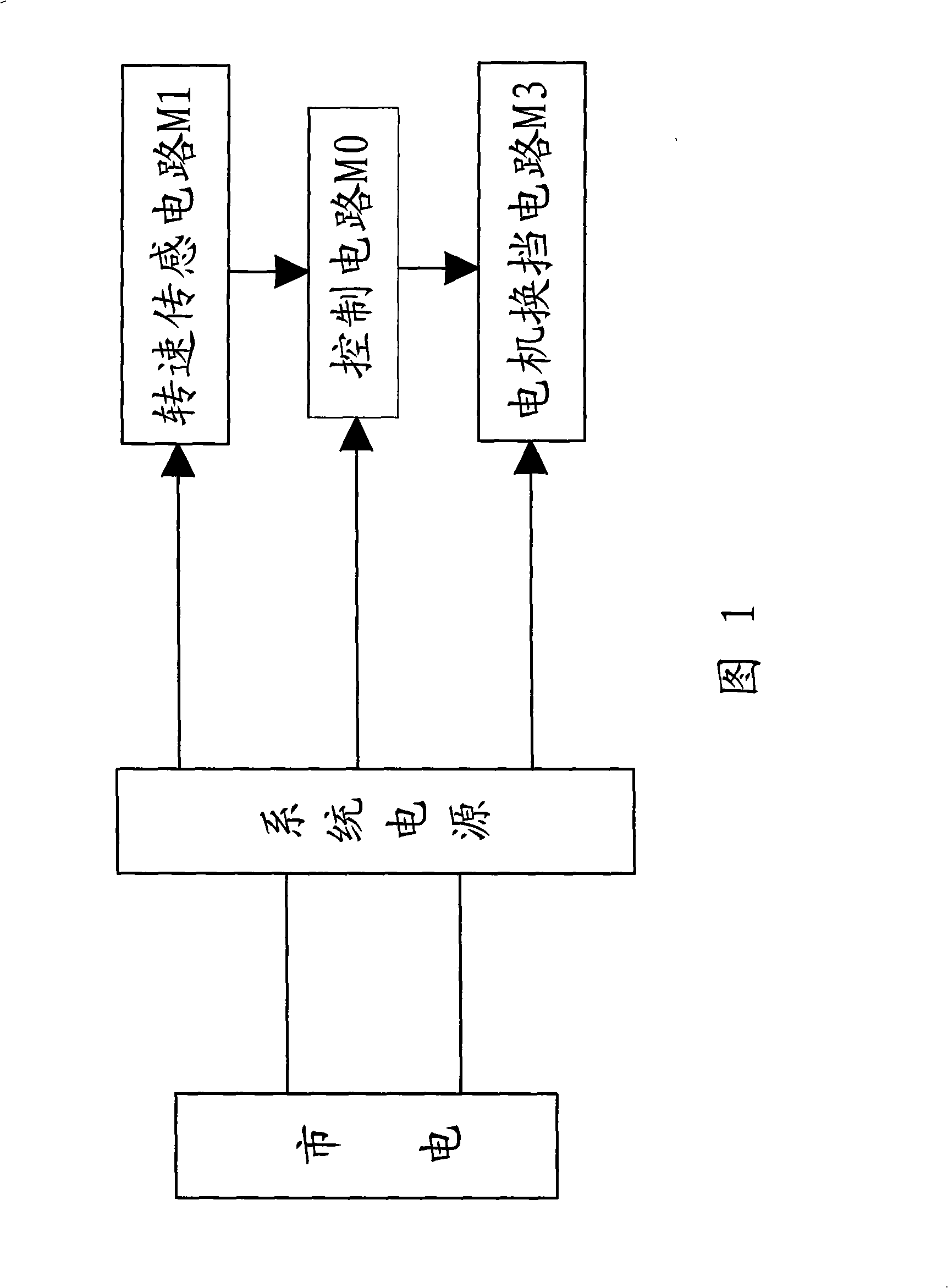

[0025] As shown in Figure 1, the automatic shifting system of this paper shredder is connected to the working circuit of the motor, including the speed sensing circuit M1, the control circuit M0, the motor switching circuit M3 and the system power supply for power supply, and the speed sensing circuit M1 The motor switching circuit M3 and the motor switching circuit M3 are both connected to the control circuit M0, the speed sensing circuit M1 is used to detect the speed of the motor M, and the control circuit M0 adjusts the output power of the motor M by controlling the motor shift circuit M3.

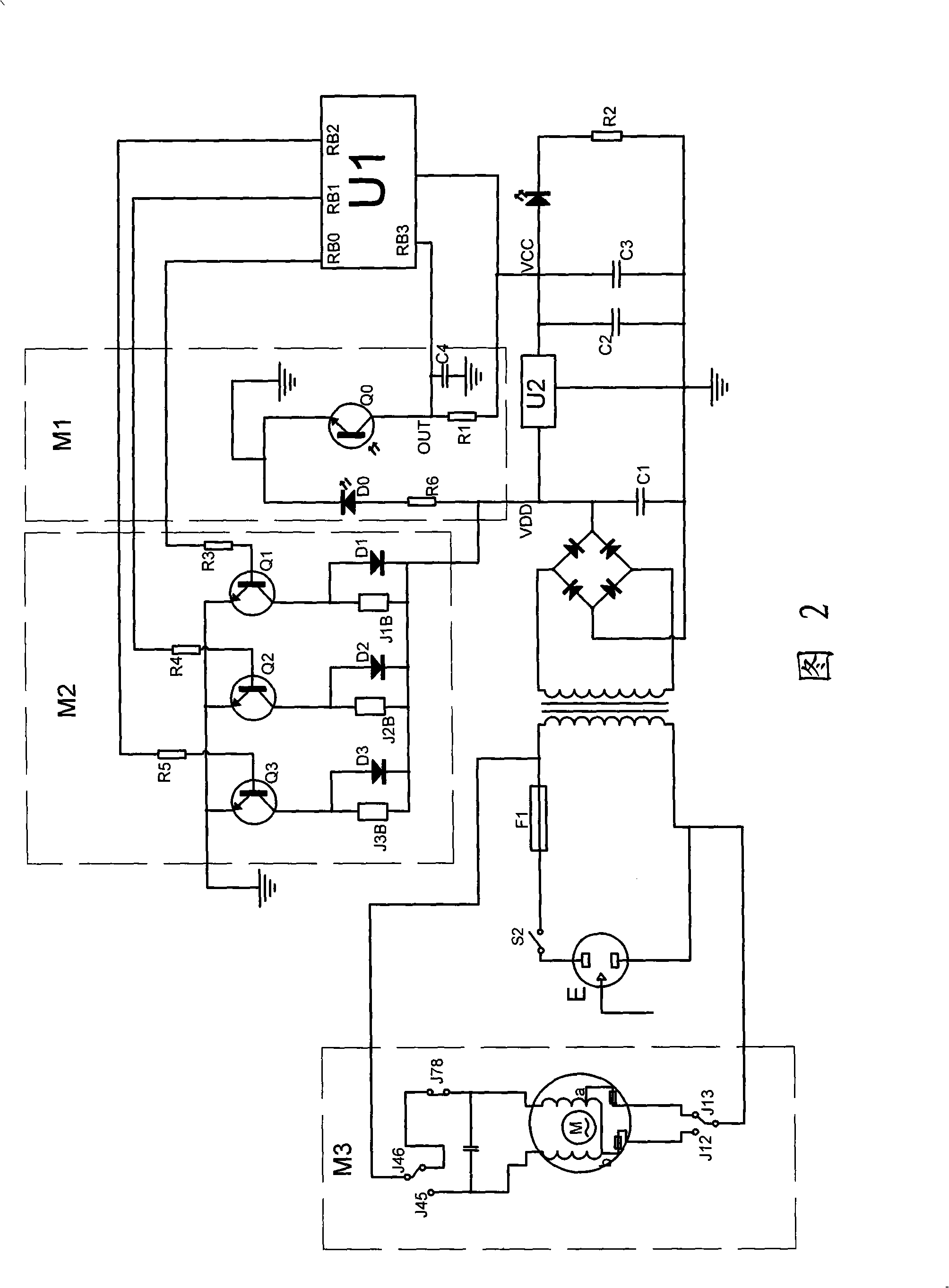

[0026] As shown in Figure 2, after the mains E is input, the alternating current is rectified into direct current after being tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com