Vortex type milk collector

A milk collector and eddy current technology, applied in the field of milk collectors, can solve problems such as unfavorable high-quality milk and milk froth, and achieve the effects of reducing foaming, stable cavity internal pressure, and breast protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the invention is described in further detail:

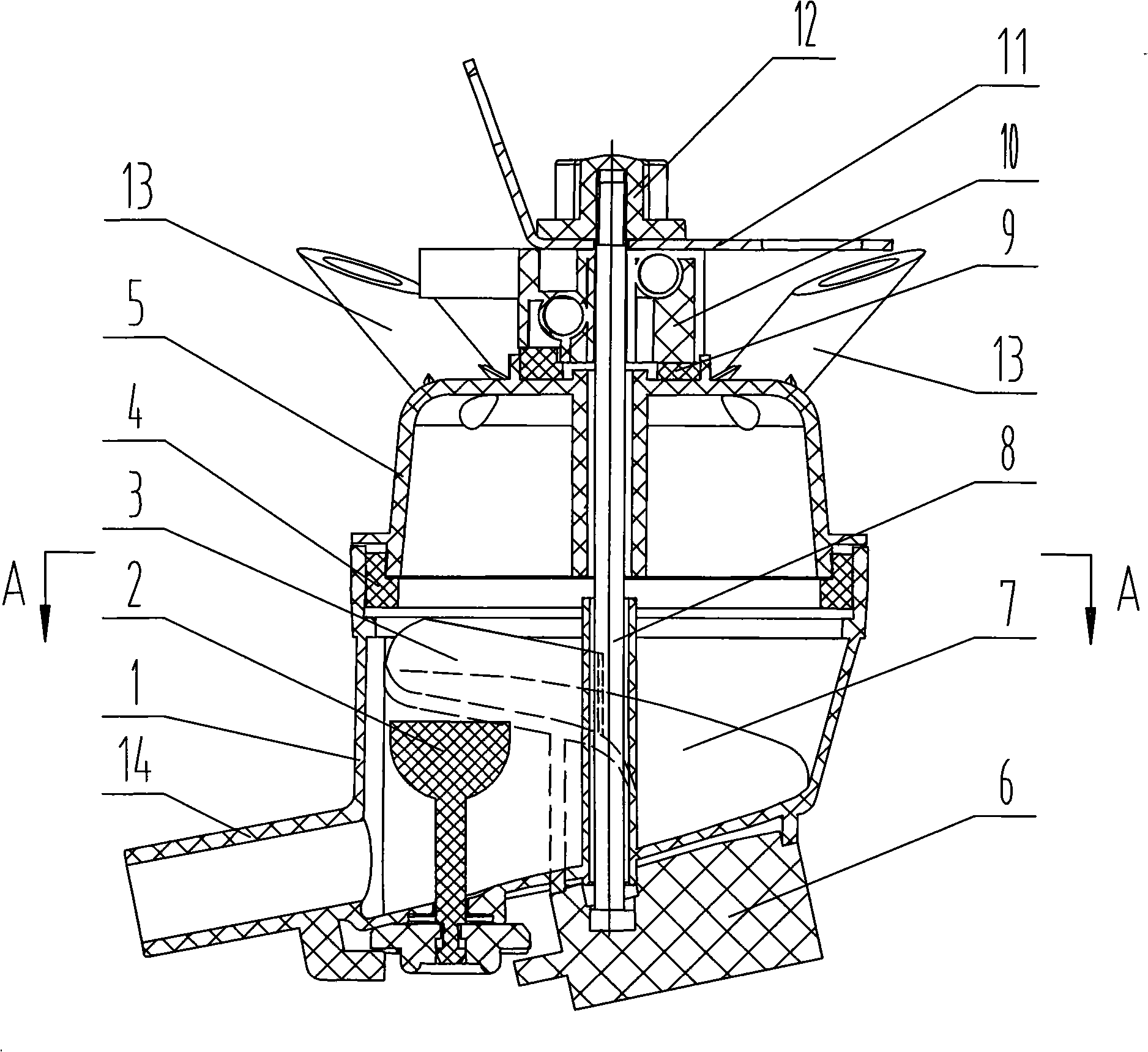

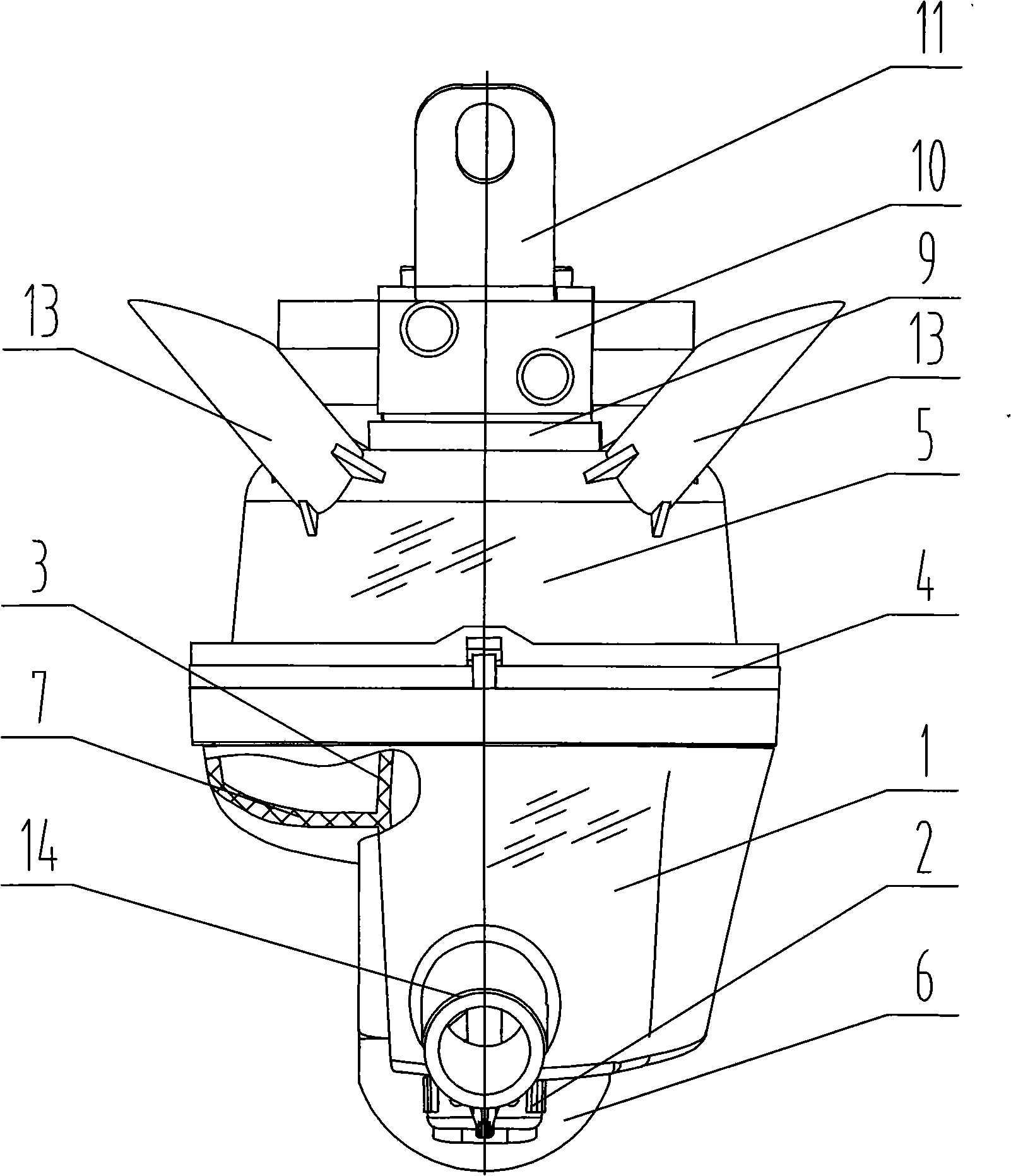

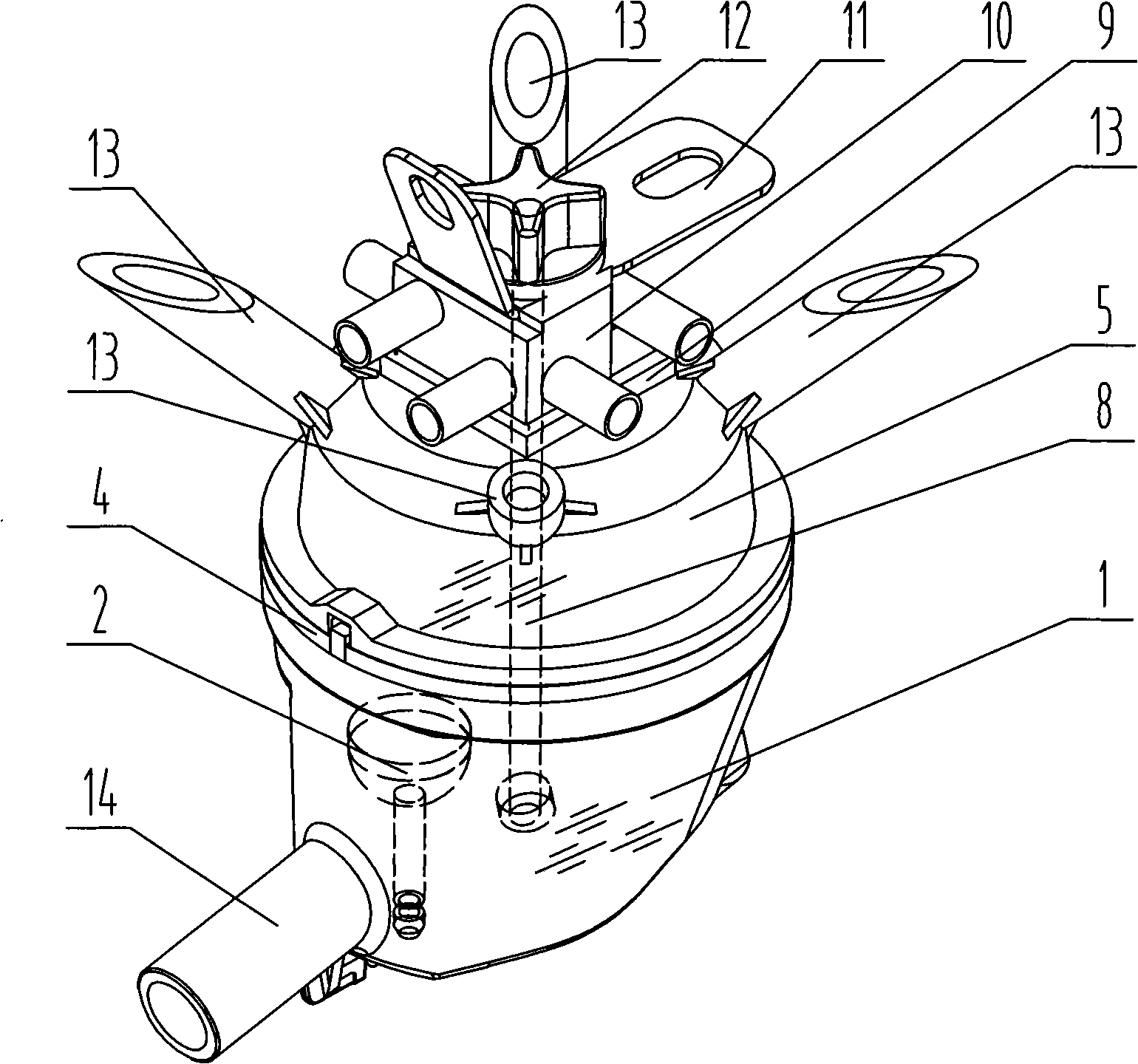

[0019] Such as figure 1 , figure 2 As shown, the structure diagram of the vortex type milk collector of the present invention is provided, including a lower chamber body 1, a rubber valve 2, an annular sealing ring 4, an upper chamber body 5, a bottom support 6, a screw rod 8, a square sleeve pad 9, Variable vacuum distribution valve 10, hook 11, wire nut 12, input joint 13, output joint 14. exist image 3 Among them, the four input connectors 13 are evenly distributed on the top of the upper chamber body 5 along the circumferential direction, and the output connectors 14 are arranged at the bottom of the lower chamber body 1. figure 1 Among them, the wire rod 8 and the plastic bottom bracket 6 are cast as one, and the lower chamber body 1 is fastened to the upper chamber body 5, and sealed by an annular sealing ring 4 embedded in the connection bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com