Liquid self-absorbing air purifier

An air purifier and self-priming technology, applied in chemical instruments and methods, using liquid separators, dispersing particle separation, etc., can solve the problems of small contact area of leaves, limited water adhering to the surface, weak purification effect, etc. The effect of good gas passage, long contact time and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

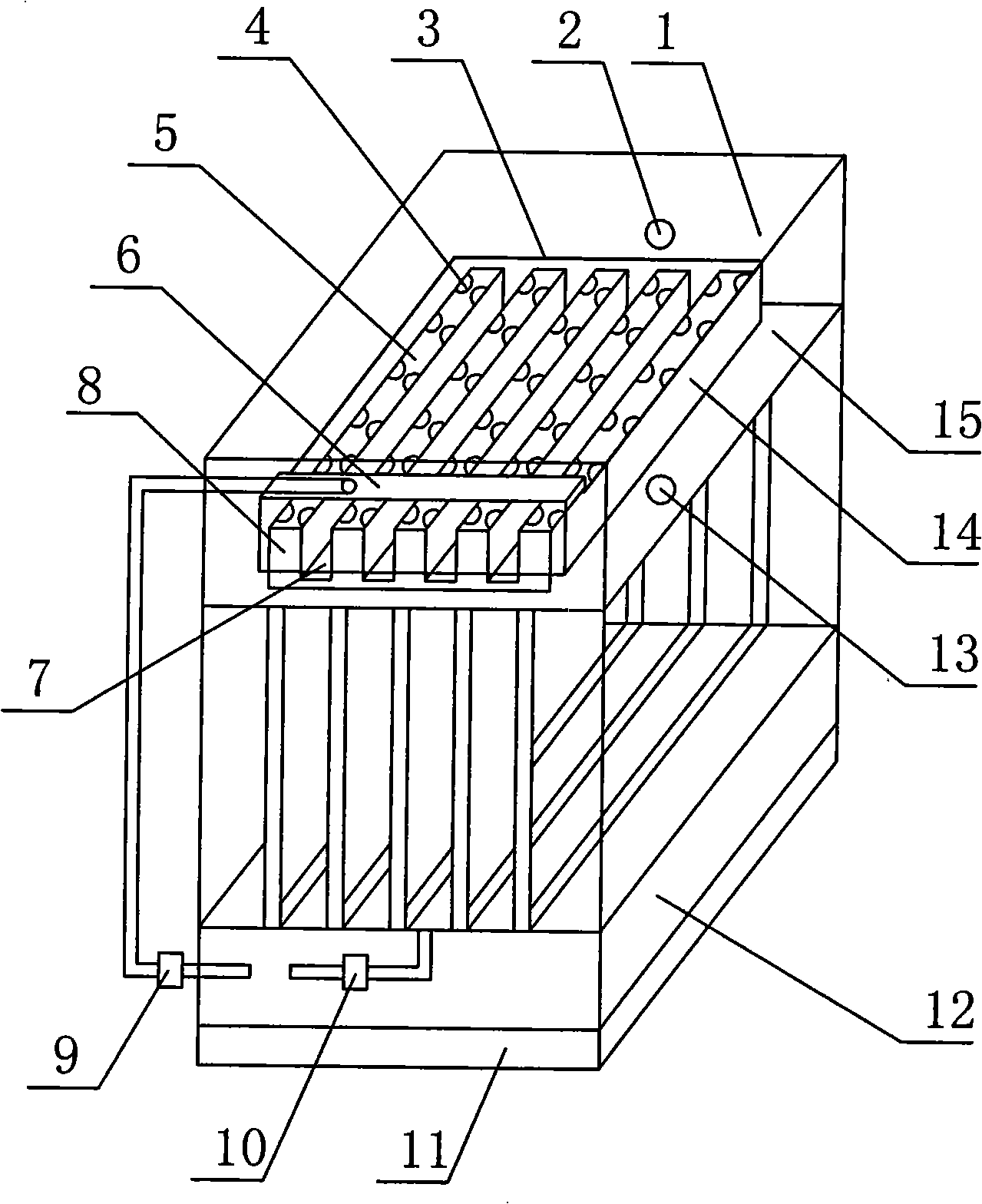

[0023] refer to figure 1 , the present embodiment includes a box body 1 provided with a liquid overflow port 2, the lower part of the box body 1 is provided with a main liquid tank 15 along the horizontal direction of the box wall, and the main liquid tank 15 is surrounded by four liquid separation tanks 7. Groove 15 is communicated with liquid separation tank 7, and liquid separation tank 7 walls are provided with deflector frame 8, and deflector frame 8 is provided with deflector 5, between deflector frame 8 inner wall and deflector 5 An upright deflector tube 4 is provided; the top of the deflector frame 8 and the deflector 5 is provided with a flat cover 3, and between the top of the flat cover 3 and the common top of the deflector frame 8 and the deflector 5 and the flat cover 3 A flat cover bracket is provided; a pressure exchange chamber 6 connected to the flat cove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com