Magnesium-base nano hydrogen-storage material and preparing method thereof

A technology for hydrogen storage materials and nanocrystals, which is applied in the field of magnesium-based nano-hydrogen storage materials and its preparation, can solve the problems of unfavorable large-scale practical application of magnesium-based hydrogen storage materials, high nickel and rare earth content, and high material cost, and achieve good results. Hydrogen absorption and desorption kinetics, high hydrogen storage capacity, and the effect of high hydrogen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a preparation method of the magnesium-based hydrogen storage material, the method comprising the steps of:

[0039] 1) Prepare a master alloy from raw materials, the composition of the obtained master alloy includes 15-25% by weight of nickel, 5-15% by weight of rare earth elements containing cerium and the balance of magnesium;

[0040] 2) Melting the obtained master alloy in the warehouse, and adopting a rapid solidification process, forming the melted master alloy into the magnesium-based hydrogen storage material; wherein, the inert gas atmosphere controls the temperature in the warehouse before and after the master alloy is melted. The pressure is such that the pressure in the chamber before the master alloy is melted is 350-500mbar, and the pressure in the chamber after the master alloy is melted is 150-350mbar.

[0041] The invention is not limited by any particular theory. However, oxidation can be prevented by passing an inert gas during...

Embodiment 1

[0053] material preparation

[0054] The raw material ratio (percentage by weight) of the master alloy of embodiment 1 is

[0055] Magnesium with 99.98% purity: 72%

[0056] 99.98% pure nickel: 20%

[0057] Rare earth elements containing cerium with a purity of 99.7%: 8%

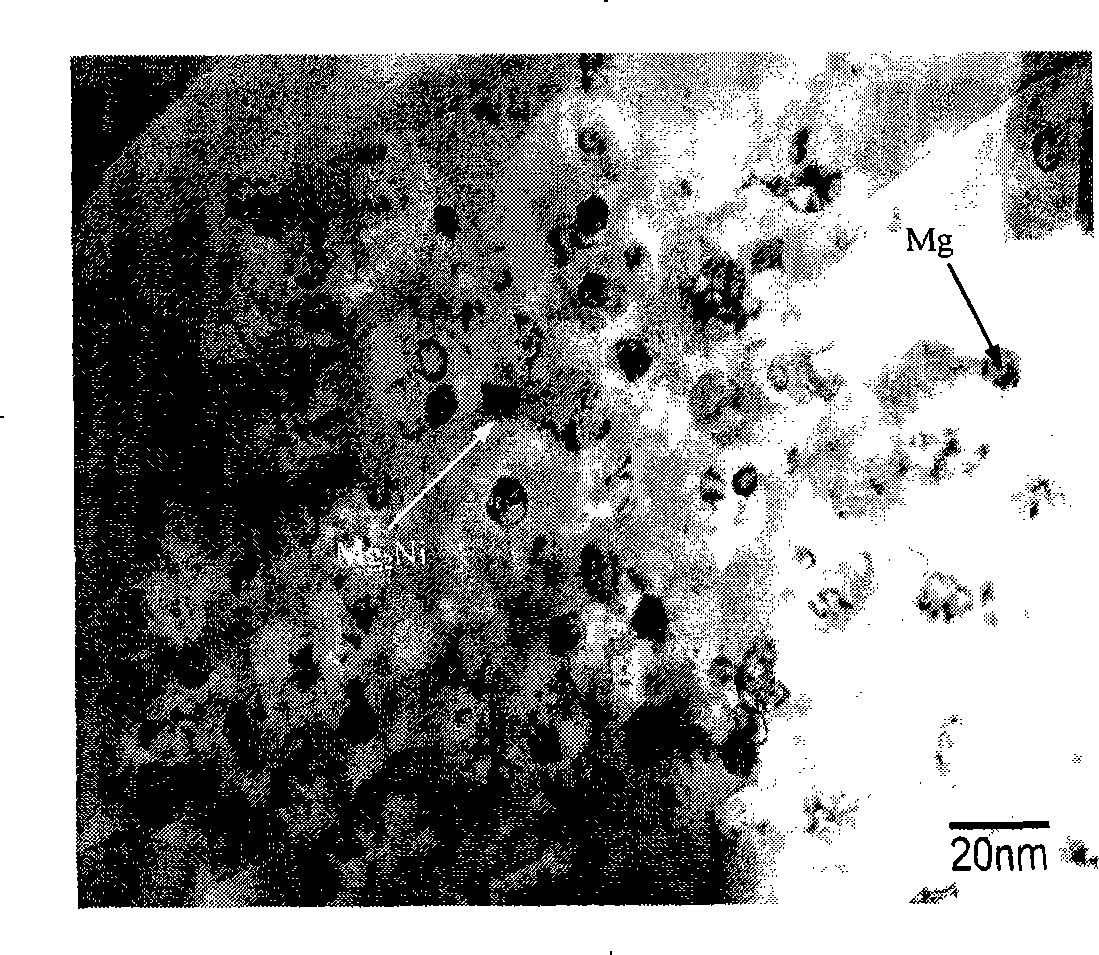

[0058] The master alloy is prepared by vacuum induction melting magnesium, nickel and cerium-containing rare earth elements according to the above ratio. Then, under the conditions of copper cooling disc and 10.5 m / s (m / s) disc rotation speed, rapid solidification is carried out under the protective atmosphere of argon, so as to obtain the material of Example 1. Wherein, the atmosphere pressure is controlled at 400mbar before the master alloy is melted, and the atmosphere pressure is controlled at 200mbar after melting. The resulting material is a strip-shaped magnesium-based hydrogen storage alloy consisting essentially of nanocrystals with a grain size of about 10 nm.

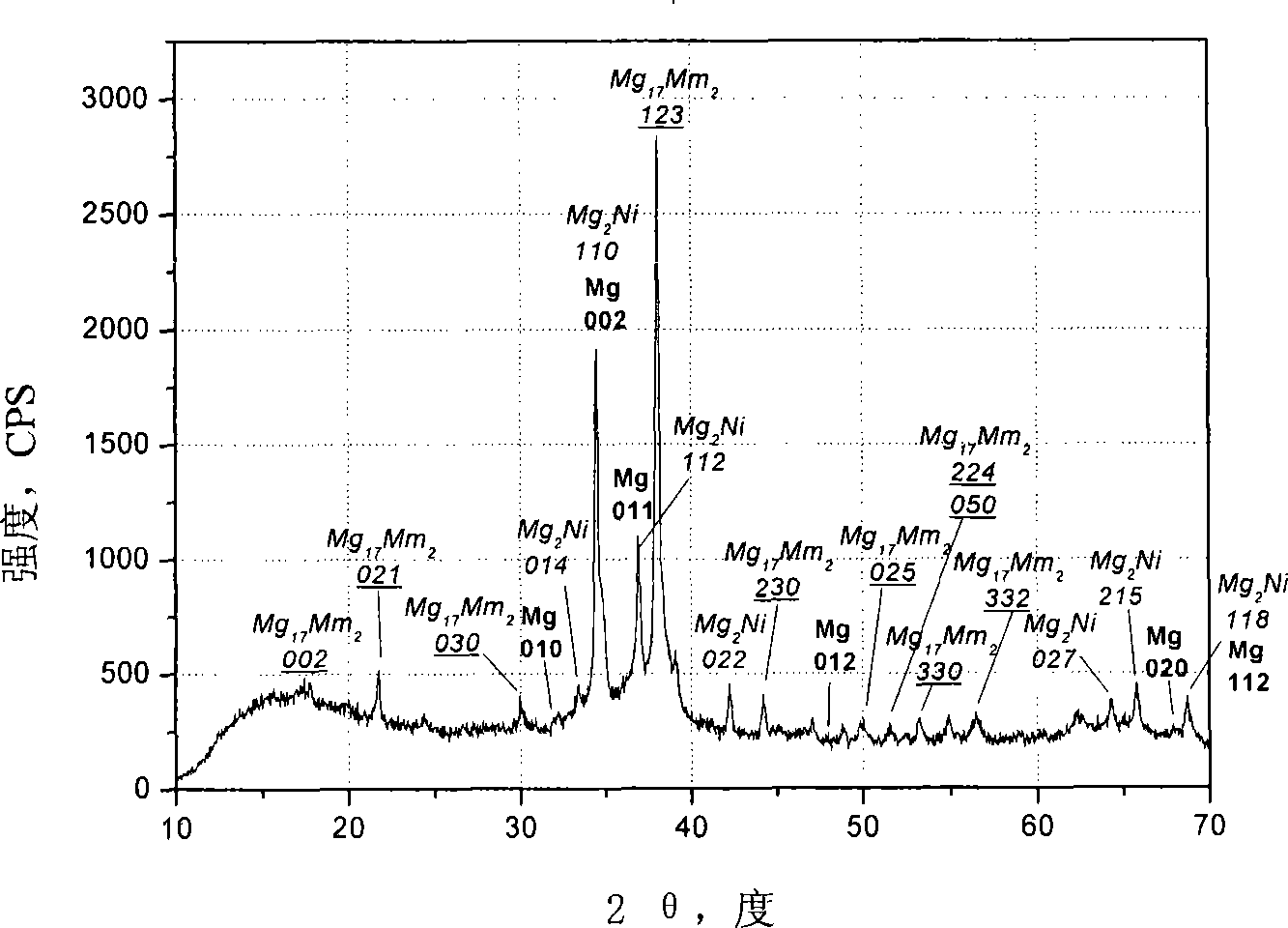

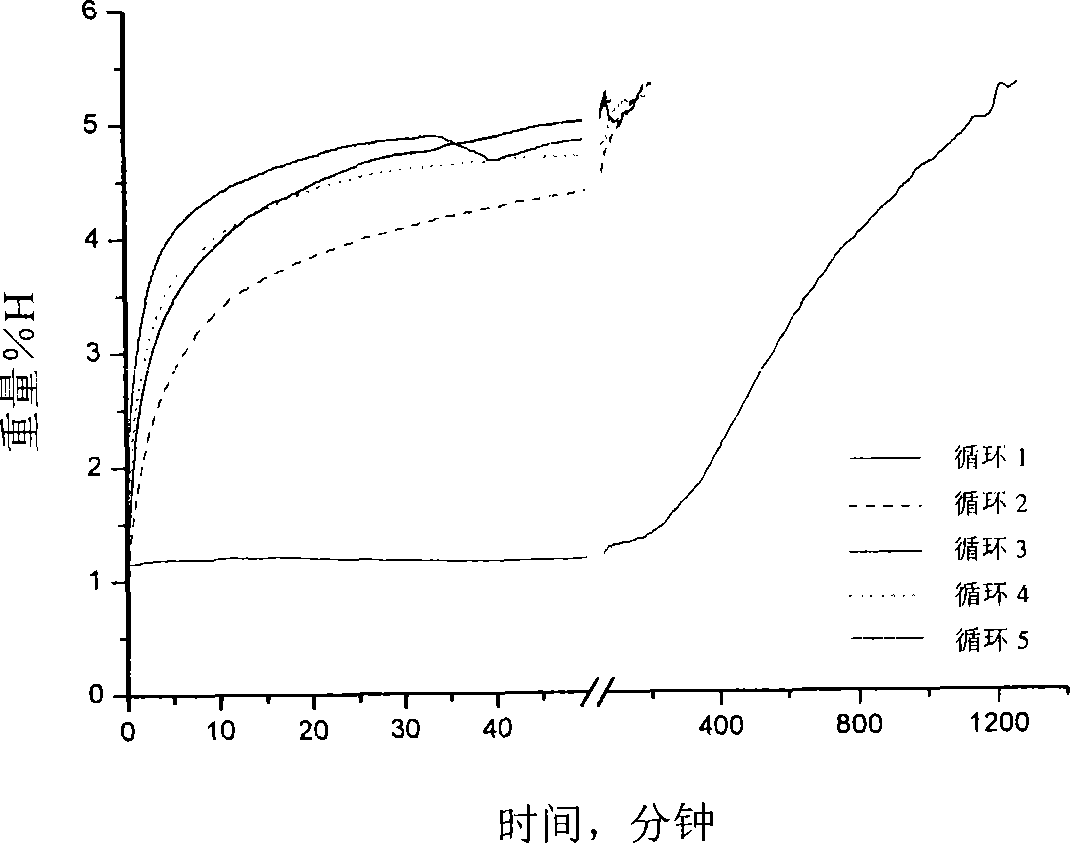

[0059] Material Characteriz...

Embodiment 2

[0063] material preparation

[0064] The raw material ratio (percentage by weight) of the master alloy of embodiment 2 is

[0065] Magnesium with 99.98% purity: 72%

[0066] 99.98% pure nickel: 22%

[0067] Rare earth elements containing cerium with a purity of 99.7%: 6%

[0068] The master alloy is prepared by vacuum induction melting magnesium, nickel and cerium-containing rare earth elements according to the above ratio. Then, rapid solidification was carried out under the conditions of copper cooling disc and 15 meters / second (m / s) disc rotation speed under the protective atmosphere of argon, so as to obtain the material of Example 2. Wherein, the atmosphere pressure is controlled at 400mbar before the master alloy is melted, and the atmosphere pressure is controlled at 200mbar after melting. The resulting material is a strip-shaped magnesium-based hydrogen storage alloy consisting essentially of nanocrystals with a grain size of about 10 nm.

[0069] Material Cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com